Preparation and application of daphne genkwa extract

The technology of extract and daikon flower is applied to the preparation and application field of fenugreek flower extract, which can solve the problems of bacteria resistance and environmental pollution, and achieve the effects of excellent antibacterial ability, excellent antibacterial range and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

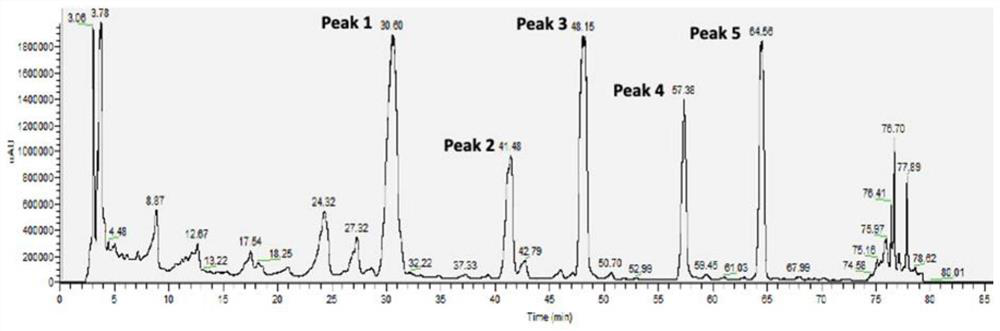

[0033] Embodiment 1: Preparation of Daphne genkwa extract

[0034] Grind the dried genkwa into powder and pass through a 20-mesh sieve. 1 liter of 80% ethanol was added to 100 grams of Daphne genkwa powder, and ultrasonic extraction was performed at 40° C. and 480 W for 1 hour. Centrifuge at 900 g for 10 minutes at room temperature, remove the supernatant, and add 1 liter of 80% ethanol to the residue for re-extraction for 1 hour. The supernatant was evaporated and concentrated in a rotary evaporator at 40°C to 1 / 5 of the original volume, and the concentrated extract was frozen at -80°C overnight and then dried in a vacuum freeze dryer to obtain Daphne genkwa extract powder. The yield of Daphne genkwa extract powder of the present invention is 13.7%.

Embodiment 2

[0035] Embodiment 2: the preparation of Daphne genkwa extract

[0036] Grind the dried genkwa into powder and pass through a 20-mesh sieve. Add 1 liter of 80% ethanol to 100 grams of Daphne genkwa powder, and ultrasonically extract at 50° C. for 1 hour at 480 W. Centrifuge at 900 g for 10 minutes at room temperature, remove the supernatant, and add 1 liter of 80% ethanol to the residue for re-extraction for 1 hour. The supernatant was evaporated and concentrated to 1 / 4 of the original volume in a rotary evaporator at 40°C, and the concentrated extract was frozen at -80°C overnight and then dried in a vacuum freeze dryer to obtain Daphne genkwa extract powder. The yield of Daphne genkwa extract powder of the present invention is 15.3%.

Embodiment 3

[0037] Embodiment 3: Preparation of Daphne genkwa extract

[0038] Grind the dried genkwa into powder and pass through a 40-mesh sieve. Add 2 liters of 80% ethanol to 100 grams of Daphne genkwa powder, and assisted ultrasonic extraction at 60°C and 480W for 2 hours. Centrifuge at 1000 g for 15 minutes at room temperature, remove the supernatant, and re-extract the residue by adding 2 liters of 80% ethanol for 2 hours. The supernatant was evaporated and concentrated to 1 / 4 of the original volume in a rotary evaporator at 40°C, and the concentrated extract was frozen at -80°C overnight and then dried in a vacuum freeze dryer to obtain Daphne genkwa extract powder. The yield of the genkwa genkwa extract powder of the present invention is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com