Intelligent explosion-proof solenoid valve

A solenoid valve, intelligent technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problem of losing the remote or automatic control valve of the cut-off valve, no control mechanism, wasting air source, etc., to improve the control reliability, The effect of preventing freezing blockage and avoiding stagnation or accumulation of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

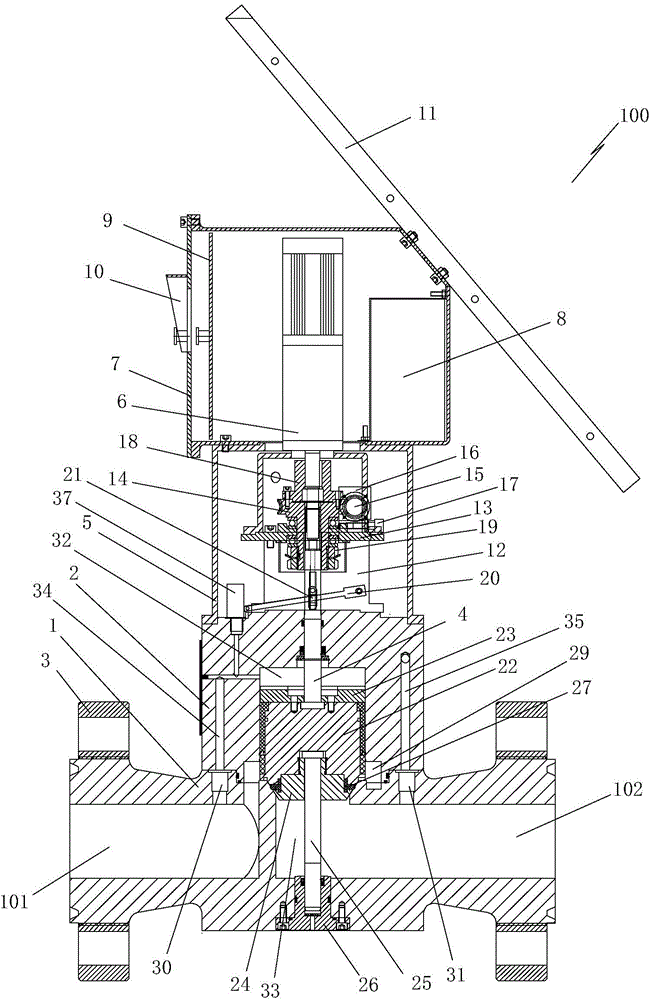

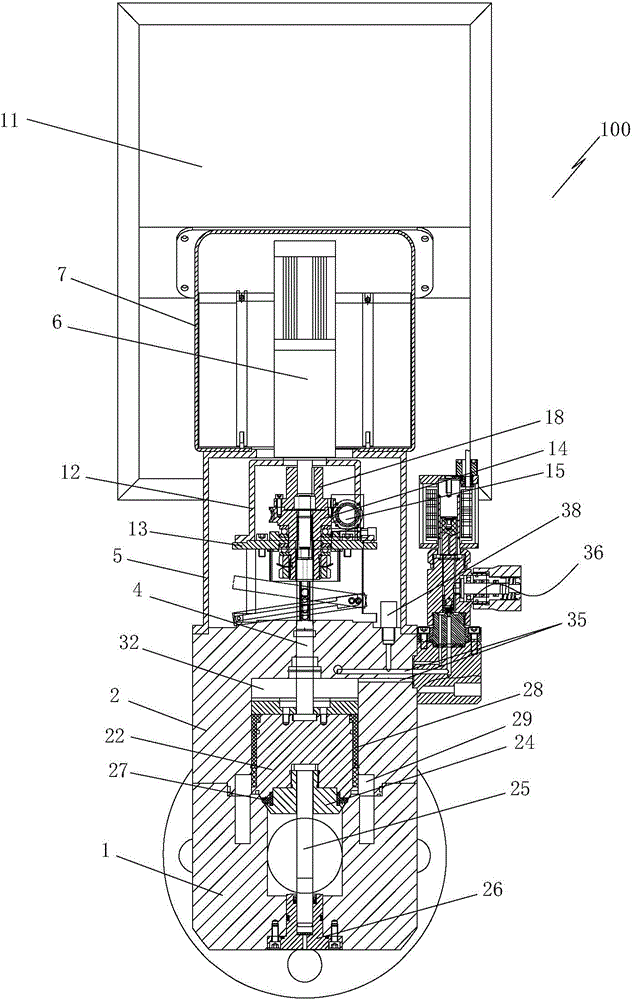

[0019] Such as figure 1 and figure 2 As shown, the present invention provides an intelligent explosion-proof solenoid valve 100, which includes a valve body 1 and a valve cover 2 arranged above the valve body 1. An air inlet passage 101 and an air outlet passage 102 are horizontally provided in the valve body 1. The inlet channel 101 and the outlet channel 102 at both ends of the valve body 1 are respectively connected to the upstream and downstream pipelines through the flange 3 . A main valve core assembly (i.e. a cut-off device) is arranged inside the valve cover 2, the upper end of the main valve core assembly is connected to a valve core lifting mechanism through a pull rod 4, the lower end of the pull rod 4 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com