Support structure for gutter cover

a support structure and gutter cover technology, applied in the field of rain gutters, can solve the problem that the majority of the prior art does not provide a means to support the width of the sectional length of the gutter cover, and achieve the effect of being easily wet by water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

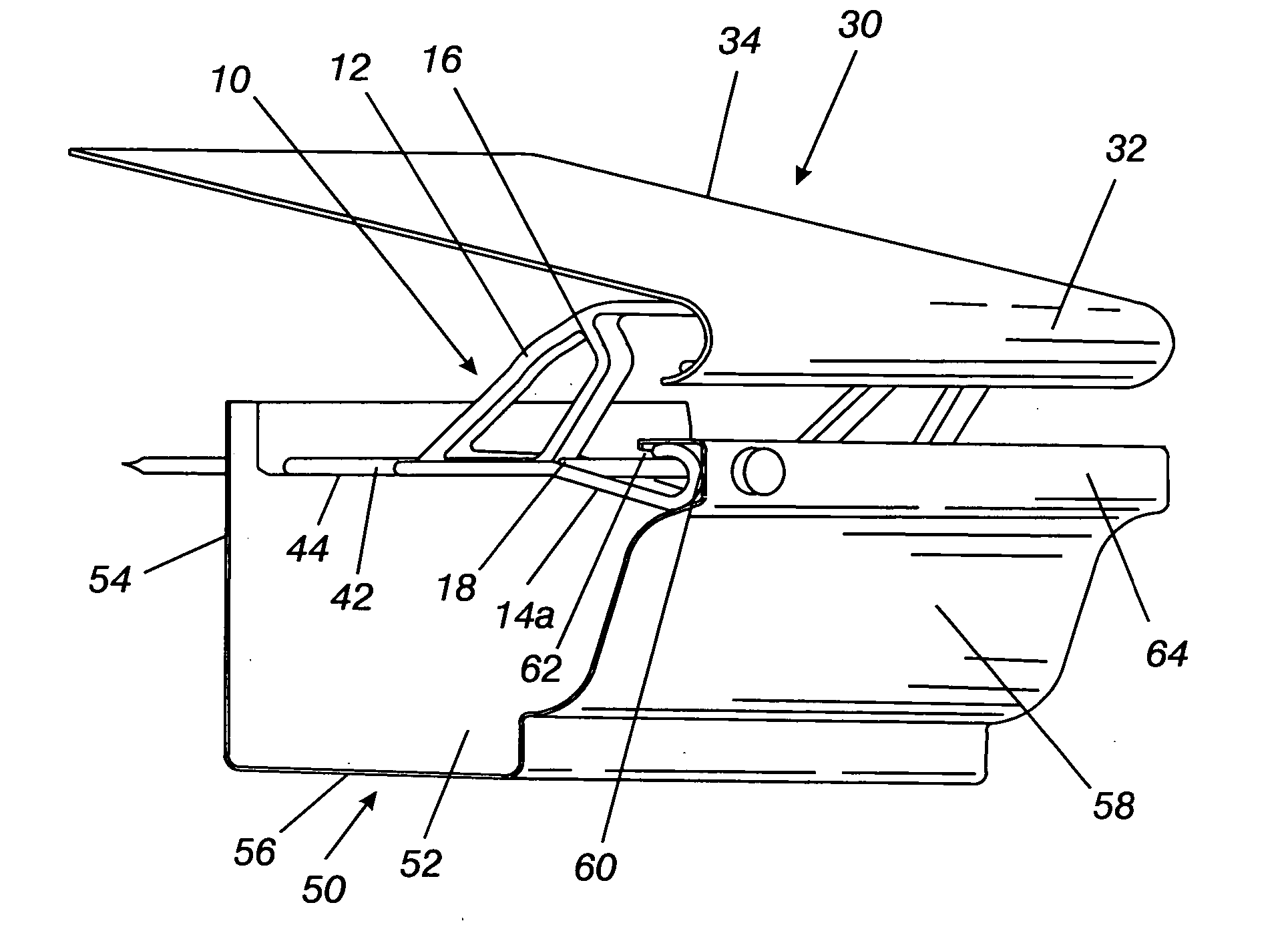

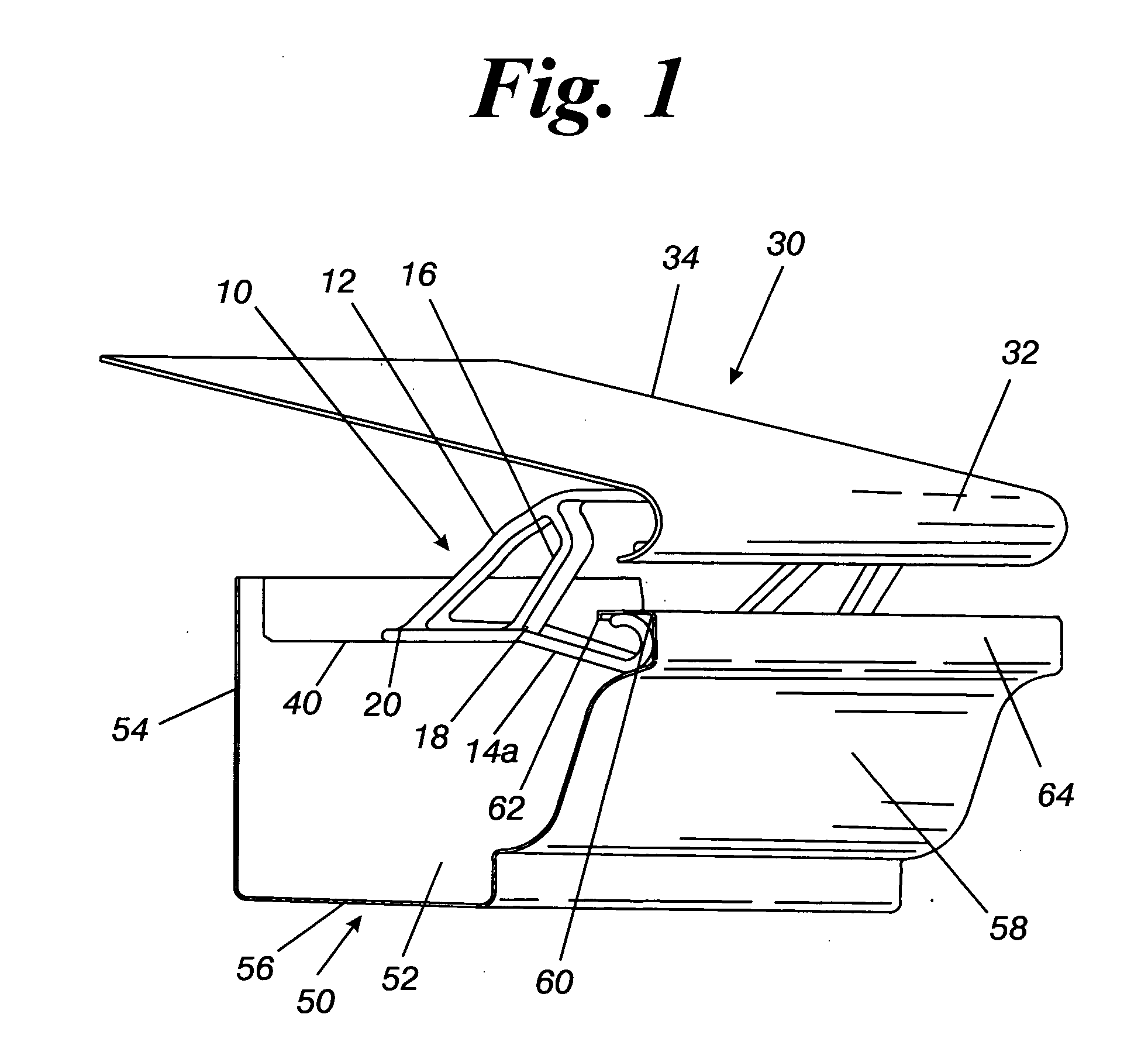

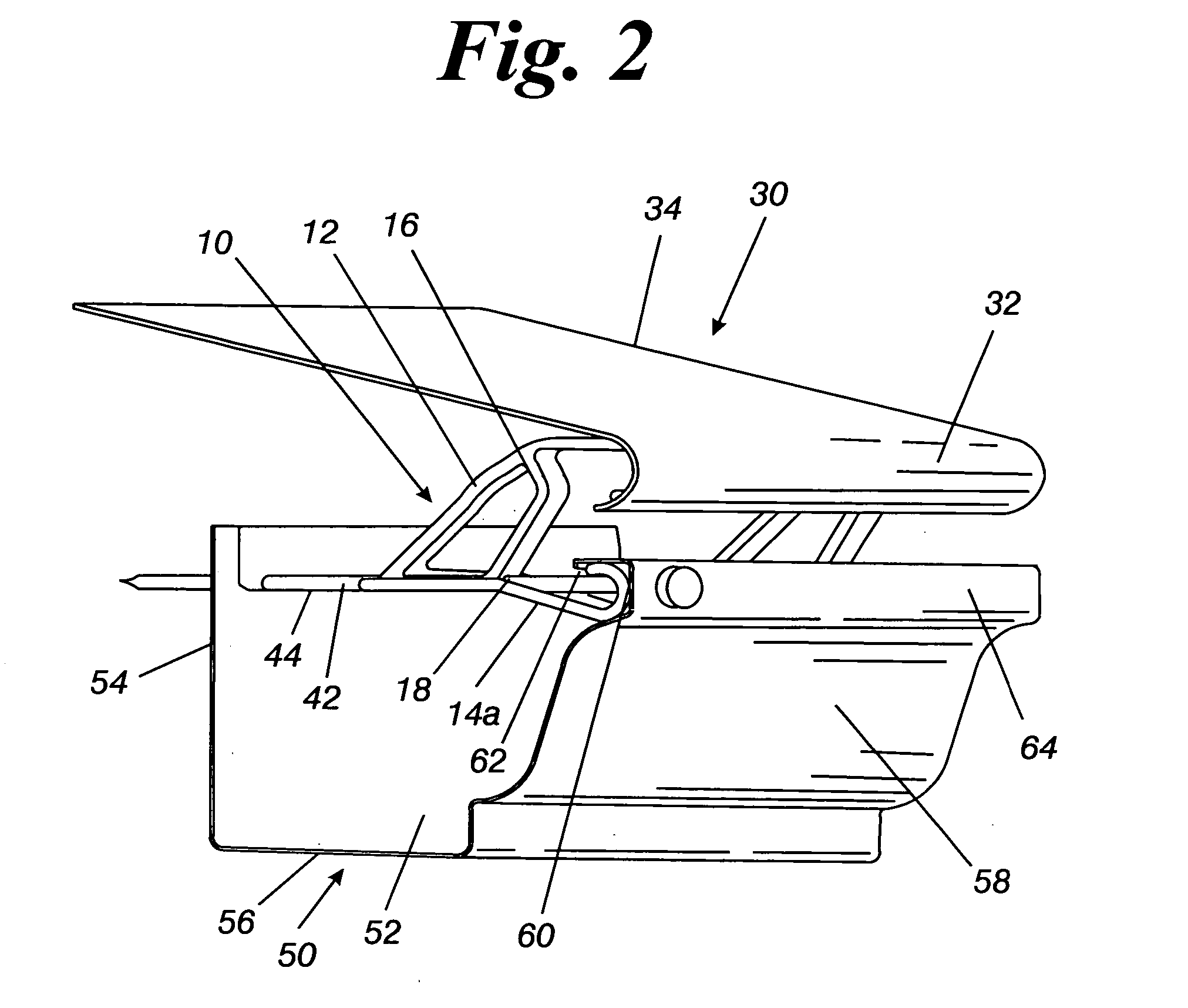

[0028] Referring now to the drawings and particularly to FIG. 1, the invention is a support structure 10 for mounting a gutter cover 30. The gutter cover 30 is installed on a sheet metal rain gutter 50, preferably made of aluminum. The rain gutter 50 has a trough 52 with a front wall 58, a bottom 56, and a rear wall 54. The rain gutter 50 is attached to a wall (not shown) of a house with hidden hanger 40. The gutter cover 30 has a substantially flat region 34 that is coextensive and underlying a course of shingles (not shown). The cover 30 is supported by lifting strut 12 that extends from junction 20 of support structure 10. The distal end of lifting strut 12 is curved, and protrudes into the inner surface of the frontal curved portion 32 of the cover 30

[0029] Referring to FIGS. 3 and 4, the support structure 10 has four struts, a lifting strut 12, two stabilizing struts 14a, 14b, and a connecting strut 16. The lifting strut 12 and the two stabilizing struts 14a, 14b converge at ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com