Injection compound and injection molding process for preparing high thermal conductivity oil-free self-lubricating hook

A self-lubricating rotary hook, high thermal conductivity technology, applied in the field of plastic injection, can solve the problems of uncontinuous production process, high production cost, low efficiency, etc., and achieves low possibility of lubricating oil pollution, high work efficiency, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

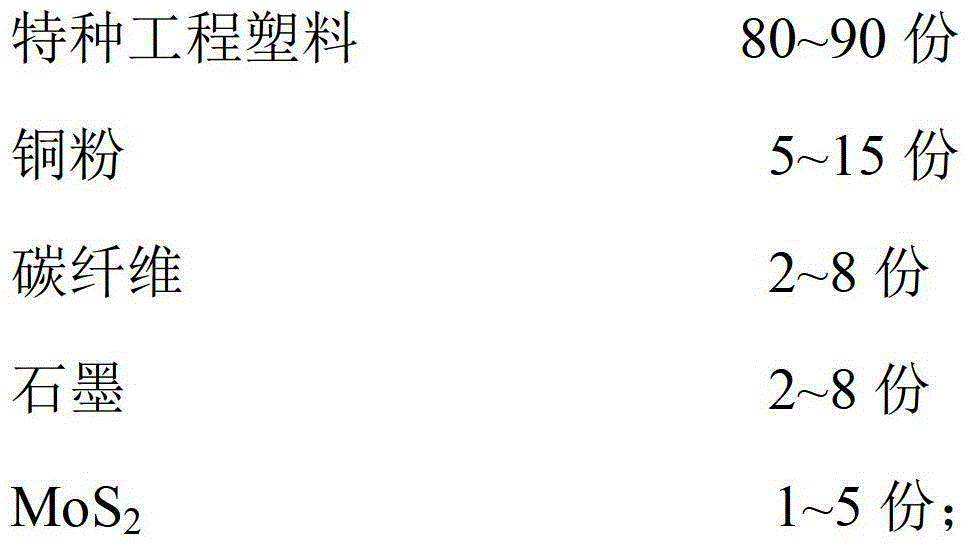

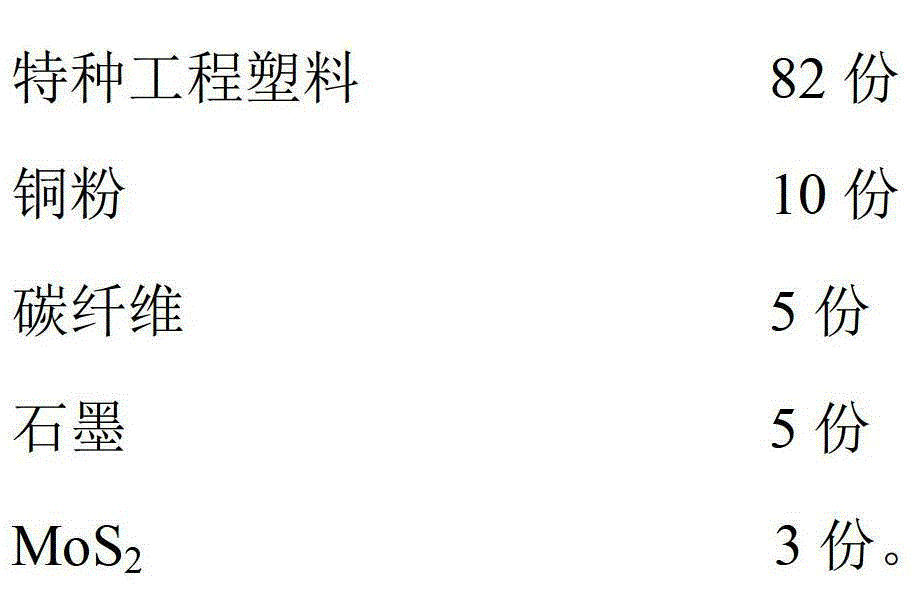

[0023] The quality composition of injection plastic is as follows:

[0024] Polyamide-imide resin (TORLONPAI-4203, Belgium Solvay (Shanghai) Co., Ltd.) 82 parts;

[0025] Copper powder (800 mesh) 10 parts;

[0026] Carbon fiber (T800 type) 5 parts;

[0027] 5 parts of graphite (800 mesh);

[0028] MoS 2 (800 mesh) 3 parts.

[0029] Injection molding process:

[0030] (1) Surface roughening sandblasting (quartz sand, Sa2.5 grade) for injection molding inserts;

[0031] (2) Heat the mold to keep the temperature of the moving mold and the static mold at 200°C;

[0032] (3) Put the injection molding insert (stainless steel) into the oven, and control the temperature of the oven at 200°C until the temperature of the injection molding insert is constant at 200°C;

[0033] (4) Take the insert for injection molding out of the oven and place it in the designated position of the mold, inject the injection molding material prepared by the formula amount of special engineering plas...

Embodiment 2

[0037] The quality composition of injection plastic is as follows:

[0038] Polyetheretherketone resin (Victrex High Performance Materials Trading (Shanghai) Co., Ltd.) 80 parts;

[0039] 12 parts of copper powder (800 mesh);

[0040] Carbon fiber (T800 type) 6 parts;

[0041] 6 parts of graphite (800 mesh);

[0042] MoS 2 (800 mesh) 4 parts.

[0043] Injection molding process:

[0044] 1. Surface roughening sandblasting (quartz sand, Sa2.5 grade) for injection molding inserts;

[0045] 2. Heat the mold to keep the temperature of the moving mold and the static mold at 200°C;

[0046] 3. Put the injection molding insert (stainless steel) into the oven, and control the temperature of the oven at 200°C until the temperature of the injection molding insert is constant at 200°C;

[0047] 4. Take the injection molding insert out of the oven and place it in the designated position of the mold, inject the injection molding material formulated with the formula amount of special ...

Embodiment 3

[0050] The quality composition of injection plastic is as follows:

[0051] Polyamide-imide resin (TORLONPAI-4203, Belgium Solvay (Shanghai) Co., Ltd.) 72 parts;

[0052] Polyetheretherketone resin (Victrex High Performance Materials Trading (Shanghai) Co., Ltd.) 10 parts;

[0053] 12 parts of copper powder (800 mesh);

[0054] Carbon fiber (T800 type) 3 parts;

[0055] 3 parts of graphite (800 mesh);

[0056] MoS 2 (800 mesh) 2 parts.

[0057] Injection molding process:

[0058] (1) Surface roughening sandblasting (quartz sand, Sa2.5 grade) for injection molding inserts;

[0059] (2) Heat the mold to keep the temperature of the moving mold and the static mold at 200°C;

[0060] (3) Put the injection molding insert (stainless steel) into the oven, and control the temperature of the oven at 200°C until the temperature of the injection molding insert is constant at 200°C;

[0061] (4) Take the injection molding insert out of the oven and place it in the designated positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com