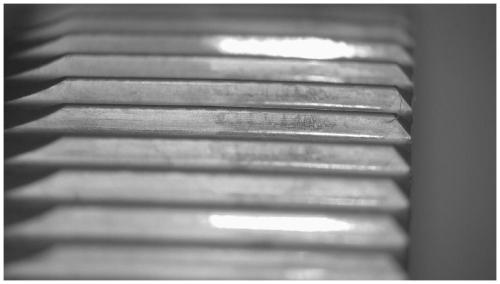

Harmonic reducer flexible gear with DLC coating

A technology of harmonic reducer and flexible wheel, which is applied in the direction of coating, superimposed layer plating, and components with teeth, etc. It can solve the problems of lower product accuracy, vibration and noise, and reduce temperature rise and noise. , Reduce friction coefficient, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to obtain a harmonic reducer flexible spline with a DLC coating, its characteristic is that the surface of the base material is distributed with a transition layer and a working layer in sequence from the inside to the outside, and the inner thickness of the transition layer is 0.4-0.6 μm. The material of the transition layer is chromium or titanium, and the thickness of the working layer is 0.8-3 μm, SP 2 Bond content is 70%-95%, SP 3 A DLC coating with a bond content of 5%-30%; the flexspline has a surface hardness of 1200 to 2500HV and a surface friction coefficient of 0.1, and the flexspline can be treated by arc ion plating as follows, the specific steps are as follows:

[0016] Step 1. Cleaning of workpiece

[0017] Before the workpiece enters the vacuum chamber for electroplating, it should be cleaned to remove some surface impurities to obtain a good electroplating effect. The specific cleaning steps can include:

[0018] (1a). Ultrasonic cleaning

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com