Al2O3-TiC/Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die and preparation method thereof

An al2o3-tic-caf2, al2o3-tic technology, applied in the field of preparation of the laminated ceramic mold, can solve the problems of high friction coefficient and poor toughness, and achieve high hardness and strength, improved toughness, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

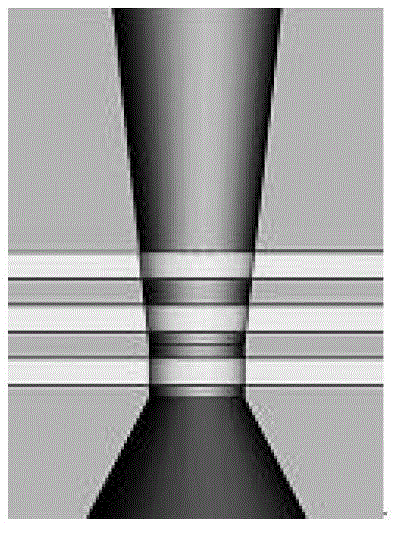

[0031] Al of the present invention 2 O 3 -TiC / Al 2 O 3 -TiC-CaF 2 The self-lubricating laminated ceramic drawing die has an aperture size of F4mm, which is prepared by a composite lamination-vacuum hot pressing sintering method in the early stage, and a two-step process of die hole grinding and processing in the later stage.

[0032] The early stage composite laminate-vacuum hot pressing sintering process is:

[0033] According to the principle of physical and chemical compatibility, the Al 2 O 3 -TiC layer ceramic powder and bonding metal powder in accordance with Al 2 O 3 :TiC:Mo:Ni=45:50:0.5:4.5 (Vol.%) to obtain Al after mixed ball milling 2 O 3 -TiC ceramic powder. Al 2 O 3 -TiC-CaF 2 Ceramic powder is also made of Al 2 O 3 Powder, TiC powder and CaF 2 Powder according to Al 2 O 3 :TiC: CaF 2 =30:60:10 (Vol.%) is obtained after mixing and ball milling. Taking full account of the contact between the metal wire and the mold in the actual drawing process, the Al 2 O 3 -TiC layer ...

Embodiment 2

[0039] It is basically the same as embodiment 1, and the difference lies in:

[0040] The die hole size of the mold is different, the die hole size is F1mm;

[0041] The post-processing process is different, the post-processing is through the EDM perforation-inner hole grinding process;

[0042] Ben Al 2 O 3 -TiC / Al 2 O 3 -TiC-CaF 2 The density of the self-lubricating laminated ceramic drawing die is 4.42g / cm 3 , The theoretical density is 4.53g / cm 3 , The hardness is 20.1GPa, and the mold has self-lubricating characteristics during the drawing process.

Embodiment 3

[0044] It is basically the same as embodiment 1, and the difference lies in:

[0045] Different laminated structure design, Al 2 O 3 -TiC layer ceramic powder and Al 2 O 3 -TiC-CaF 2 The layered ceramic powder is designed in a laminated structure with a volume ratio of 12:2:1:2:1:2:20 from bottom to top in the graphite mold, and the unit volume thickness is 0.5mm.

[0046] Ben Al 2 O 3 -TiC / Al 2 O 3 -TiC-CaF 2 The density of the self-lubricating laminated ceramic drawing die is 4.40g / cm 3 , The theoretical density is 4.56g / cm 3 , The hardness is 20.4GPa, and the mold has self-lubricating characteristics during the drawing process.

[0047] In summary, the Al prepared by the manufacturing method of the present invention 2 O 3 -TiC / Al 2 O 3 -TiC-CaF 2 The self-lubricating laminated ceramic drawing die not only has the characteristics of high hardness, high strength and good toughness, but also has self-lubricating properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Theoretical density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com