Composite coating for lead-based reactor pump impeller and preparation method of composite coating

A lead-based reactor, composite coating technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems of liquid lead alloy corrosion of structural materials, etc., to alleviate the problem of cracking and peeling, good resistance to lead Alloy corrosion performance, thermal stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

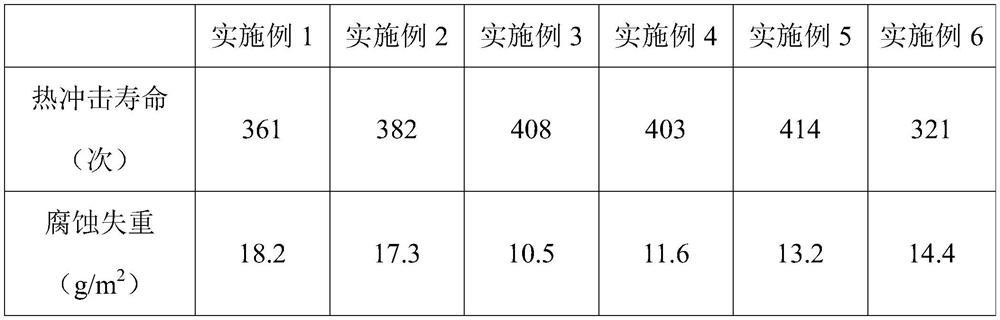

Examples

Embodiment 1

[0030] The composite coating for a lead-based reactor pump impeller of this embodiment adopts a three-layer gradient composite structure; the innermost layer of the three-layer gradient composite structure is composed of a high-entropy alloy coating whose chemical composition and thermal expansion coefficient match the metal matrix The outermost layer is made of Ti with good wear resistance and excellent corrosion resistance to lead alloy erosion. 3 AlC 2 Coating, the middle layer is made of high entropy alloy and Ti 3 AlC 2 Composite coating, and the Ti in the middle layer 3 AlC 2 The mass ratio is 50%. Wherein, the high-entropy alloy used in the innermost layer and the middle layer is specifically composed of Fe, Cr, Ni, and Al in a molar ratio of 1:1:1:1.

[0031] The preparation method of the composite coating for the above-mentioned lead-based reactor pump impeller:

[0032] S1, preparation of spray powder

[0033] Innermost layer: The spray powder is high-entropy ...

Embodiment 2

[0043] The composite coating for a lead-based reactor pump impeller of this embodiment adopts a three-layer gradient composite structure; the innermost layer of the three-layer gradient composite structure is composed of a high-entropy alloy coating whose chemical composition and thermal expansion coefficient match the metal matrix The outermost layer is made of Ti with good wear resistance and excellent corrosion resistance to lead alloy erosion. 3 AlC 2 Coating, the middle layer is made of high entropy alloy and Ti 3 AlC 2 Composite coating, and the Ti in the middle layer 3 AlC 2 The mass ratio is 50%. Wherein, the high-entropy alloy used in the innermost layer and the middle layer is specifically composed of Fe, Cr, Ni, Al, and Ti in a molar ratio of 1:1:1:1:0.2.

[0044] The preparation method of the composite coating for the above-mentioned lead-based reactor pump impeller:

[0045] S1, preparation of spray powder

[0046] Innermost layer: The spray powder is high-...

Embodiment 3

[0056] The composite coating for a lead-based reactor pump impeller of this embodiment adopts a three-layer gradient composite structure; the innermost layer of the three-layer gradient composite structure is composed of a high-entropy alloy coating whose chemical composition and thermal expansion coefficient match the metal matrix The outermost layer is made of Ti with good wear resistance and excellent corrosion resistance to lead alloy erosion. 3 AlC 2 Coating, the middle layer is made of high entropy alloy and Ti 3 AlC 2 Composite coating, and the Ti in the middle layer 3 AlC 2 The mass ratio is 50%. Wherein, the high-entropy alloy used in the innermost layer and the middle layer is specifically composed of Fe, Cr, Ni, Al, and Ti in a molar ratio of 1:1:1:1:0.2.

[0057] The preparation method of the composite coating for the above-mentioned lead-based reactor pump impeller:

[0058] S1, preparation of spray powder

[0059] Innermost layer: The spray powder is high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com