Manufacturing method of bearing and manufacturing method of harmonic reducer

A technology of a harmonic reducer and a manufacturing method, applied in the directions of bearing components, shafts and bearings, transmission parts, etc., can solve the problems of large friction of cross bearings, failure of lubrication, high carbonization of grease, etc., to reduce friction and reduce use. amount, the effect of reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

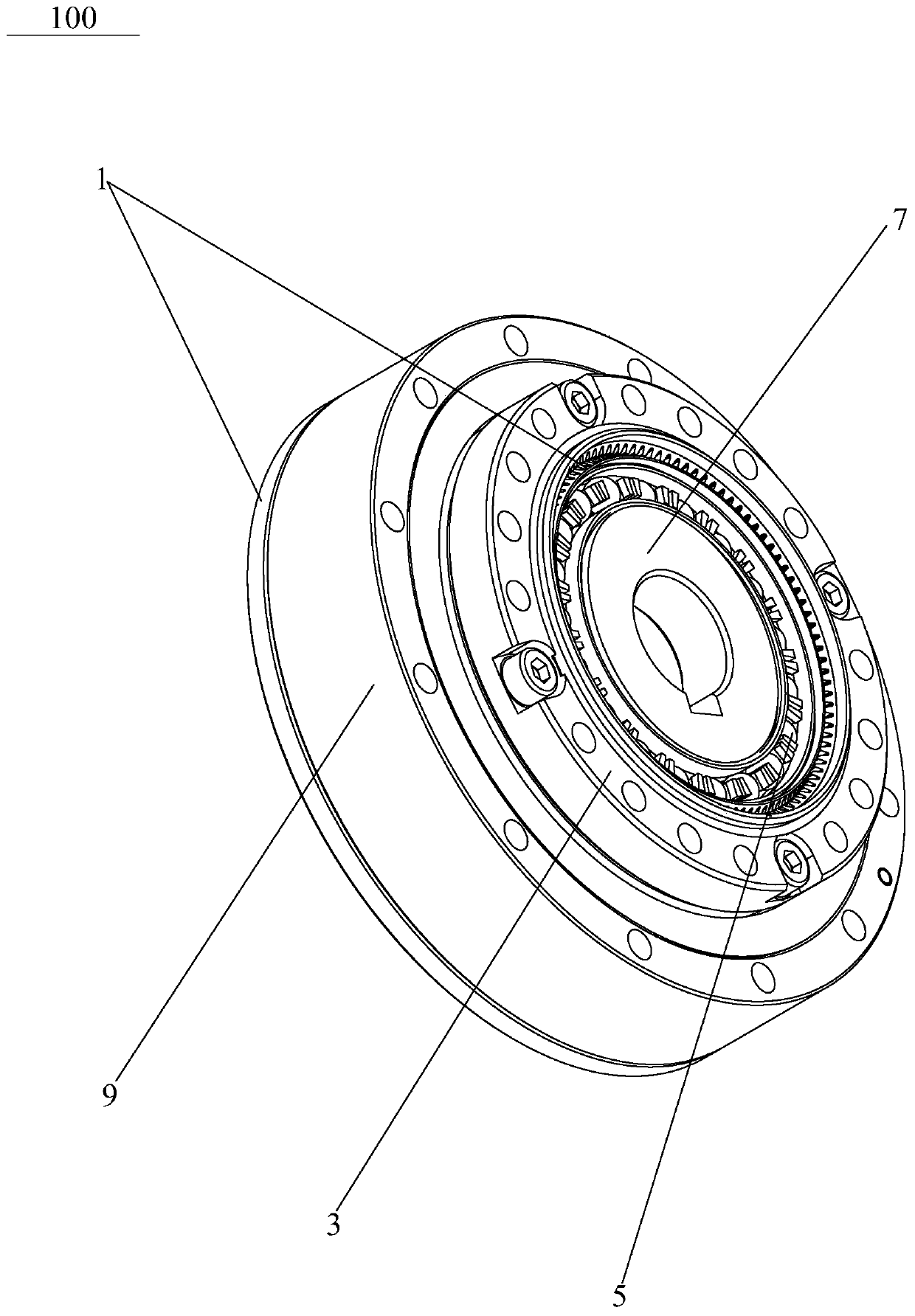

[0092] Such as figure 1 The manufacturing method of the shown harmonic reducer 100 (model: 14-50) includes the following steps:

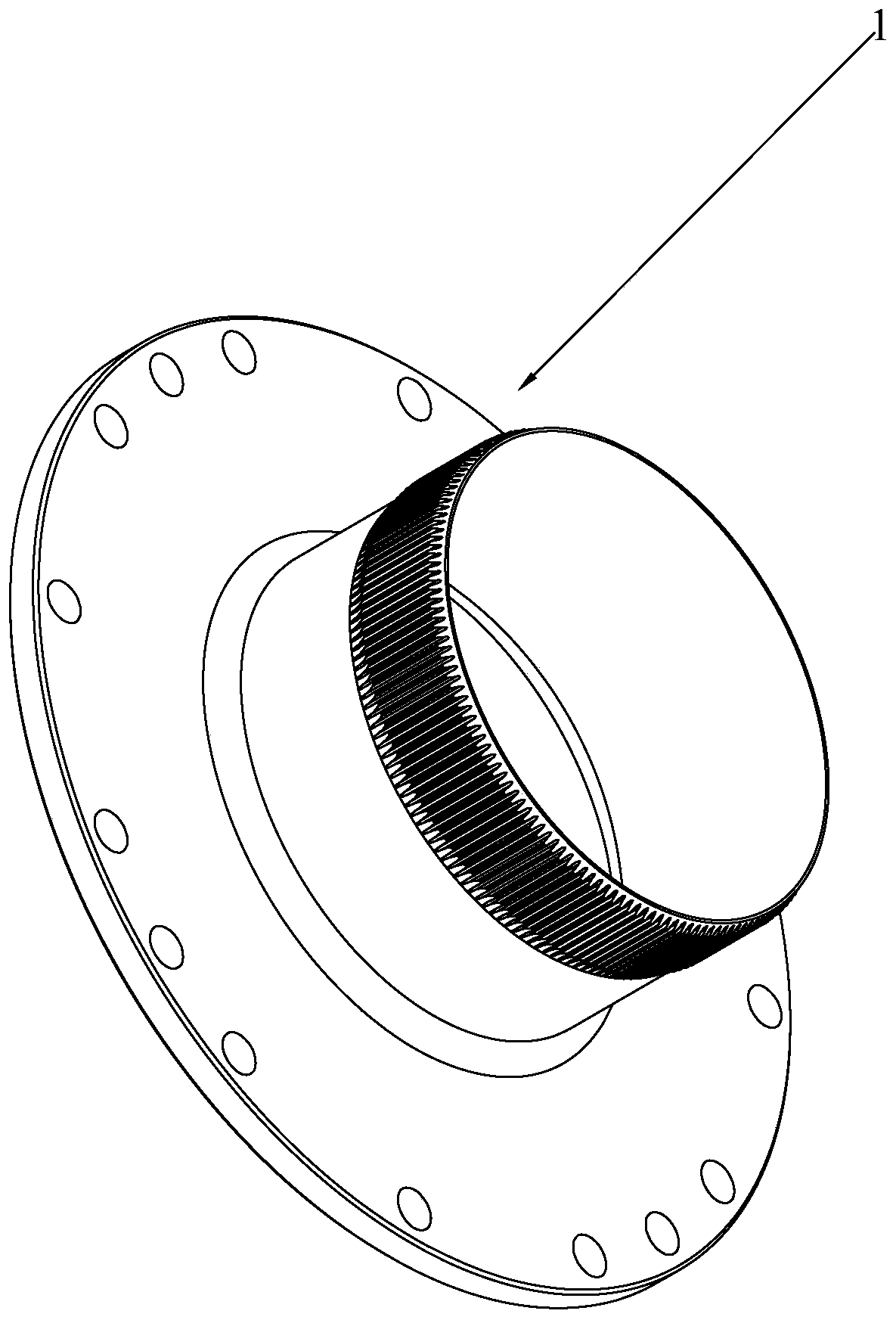

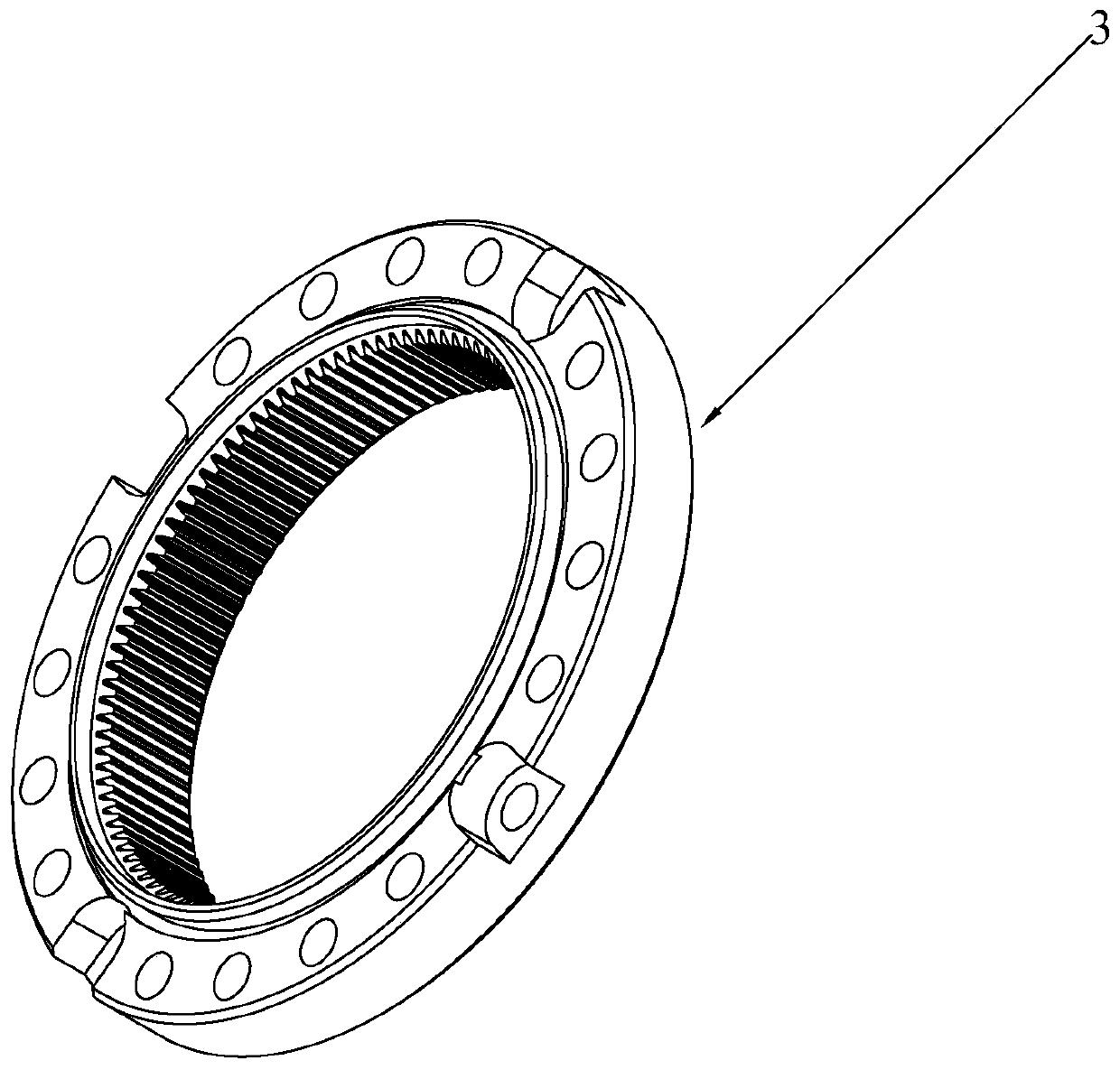

[0093] (1) Processing of flexible spline 1 and rigid spline 3

[0094] The processing procedure of the flexible wheel 1 is: lowering the bar - forging (forging the bar into a ring, and the initial temperature of the forging is 1150°C, and the end temperature is 850°C) - annealing - spinning (spinning the workpiece into a Thin-walled solid ring, and reserved machining allowance) - quenching and tempering (hardness control is HRC35) - rough turning - finishing turning - surface hardening (hardness control is HRC45) - sandblasting (only thin-walled parts) - Double end surface fine grinding (surface roughness is 0.4μm, surface parallelism is 1μm)-inner and outer circle fine grinding (surface roughness is 0.4μm)-screw hole machining-the first ultrasonic cleaning and drying-ultra-precision gear shaping ( The surface roughness is maintained at 0.4 μm) - ...

Embodiment 2

[0108] Such as figure 1 The manufacturing method of the shown harmonic reducer 100 (model: 40-160) includes the following steps:

[0109] (1) Processing of flexible spline 1 and rigid spline 3

[0110] The processing procedure of the flexible wheel 1 is: lowering the bar - forging (forging the bar into a ring, and the initial temperature of the forging is 1150°C, and the end temperature is 850°C) - annealing - spinning (spinning the workpiece into a Thin-walled solid ring, and reserved machining allowance) - quenching and tempering (hardness control is HRC35) - rough turning - finishing turning - surface hardening (hardness control is HRC45) - sandblasting (only thin-walled parts) - Double end surface fine grinding (surface roughness is 0.4μm, surface parallelism is 1μm)-inner and outer circle fine grinding (surface roughness is 0.4μm)-screw hole machining-the first ultrasonic cleaning and drying-ultra-precision gear shaping or Gear hobbing (surface roughness maintained at 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com