A kind of preparation method of high-performance dragon belt

A high-performance, dragon-belt technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problem of increased wear, achieve moderate cost, good strength, and improve practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

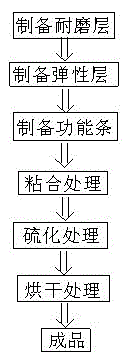

Image

Examples

Embodiment 1

[0018] Concrete preparation process is as follows:

[0019] a) Prepare the wear-resistant layer. The main components and percentage ratio of the wear-resistant layer are: 85% NBR, 5% ceramic particles, 4% resin, and the rest are additives; the preparation process of the wear-resistant layer is as follows: Mixing, kneading, calendering, trimming, etc., the total thickness of the wear-resistant layer is about 1.4mm; among them, the kneading temperature is controlled at 75 ° C, and the time is 18 minutes; during the rolling process, the wear-resistant layer A groove structure is formed in the middle of the upper surface, the depth of the groove structure is about 0.5mm, and the width is about 1 / 3 of the total width of the wear-resistant layer;

[0020] b) Prepare the elastic layer. The main material of the elastic layer is chloroprene rubber. The preparation process includes: raw material melting, calendering, film forming and trimming, etc. The thickness of the prepared elastic ...

Embodiment 2

[0026] Concrete preparation process is as follows:

[0027] a) Prepare the wear-resistant layer. The main components and percentage ratio of the wear-resistant layer are: 88% NBR, 4% ceramic particles, 3% resin, and the rest are additives; the preparation process of the wear-resistant layer is as follows: Mixing, kneading, rolling, trimming, etc., the total thickness of the wear-resistant layer is about 1.4mm; among them, the kneading temperature is controlled at 80 ° C, and the time is 15 minutes; during the rolling process, the wear-resistant layer A groove structure is formed in the middle of the upper surface, the depth of the groove structure is about 0.5mm, and the width is about 1 / 3 of the total width of the wear-resistant layer;

[0028] b) Prepare the elastic layer. The main material of the elastic layer is chloroprene rubber. The preparation process includes: raw material melting, calendering, film forming and trimming, etc. The thickness of the prepared elastic laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com