Flexible graphite folding type rotary kiln sealing device

A technology of flexible graphite and sealing devices, which is applied in the direction of rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of graphite block bearing large extrusion force, leakage of protective gas, sealing failure, etc., and achieves simple structure, Low proportion of gas leakage, effect of compensating axial deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

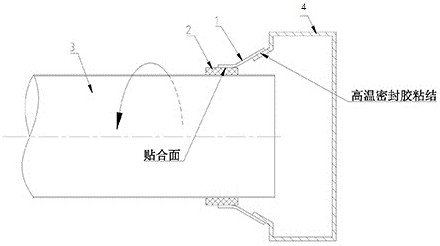

[0018] see figure 1 , this embodiment provides a flexible graphite folding rotary kiln sealing device, including a folding belt 1, a wear-resistant ring 2, a rotary kiln shell 3 and a cover 4, and the wear-resistant ring 2 is socketed and fixed on the rotary kiln shell 3 In the circumferential direction, the folding belt 1 is in the shape of a conical ring, and its small end is closely attached to the wear-resistant ring 2, and the large end is bonded and fixed to the cover body 4 through high-temperature-resistant glue.

[0019] The axes of the overlapping belt 1, the wear-resistant ring 2, the rotary kiln shell 3 and the cover body 4 are located on the same axis, and the angle between the hypotenuse of the folding belt 1 and the axis is 15°~45°.

[0020] The inner surface of the small head end of the folding belt 1 is placed on the outer surface of the wear-resistant ring 2, and the two fit together to produce relative slippage.

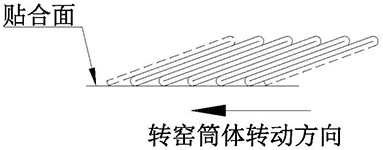

[0021] like figure 2 As shown, the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com