Durable washing machine seal ring

A technology for washing machines and sealing rings, which is applied to engine sealing, mechanical equipment, engine components, etc., can solve the problems of reduced sealing performance, damage, and sealing failure, and achieve the effects of improving sealing effect, strong resistance, and stable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

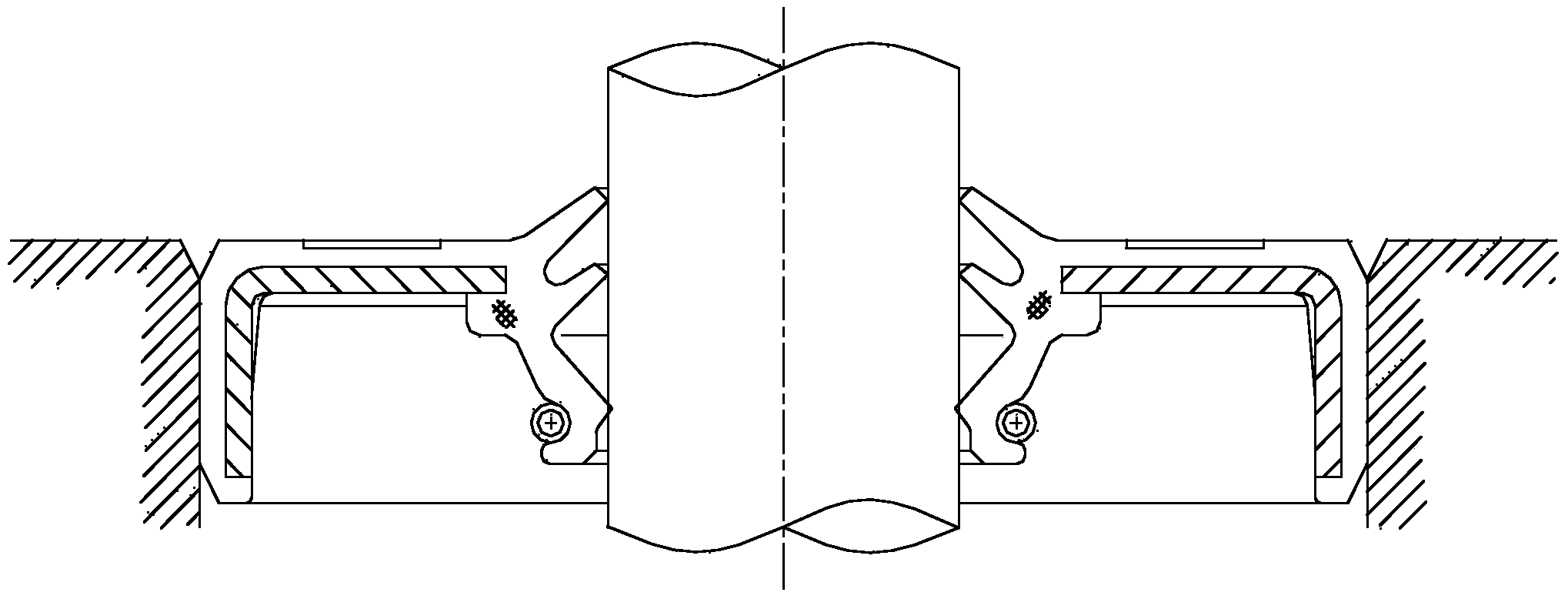

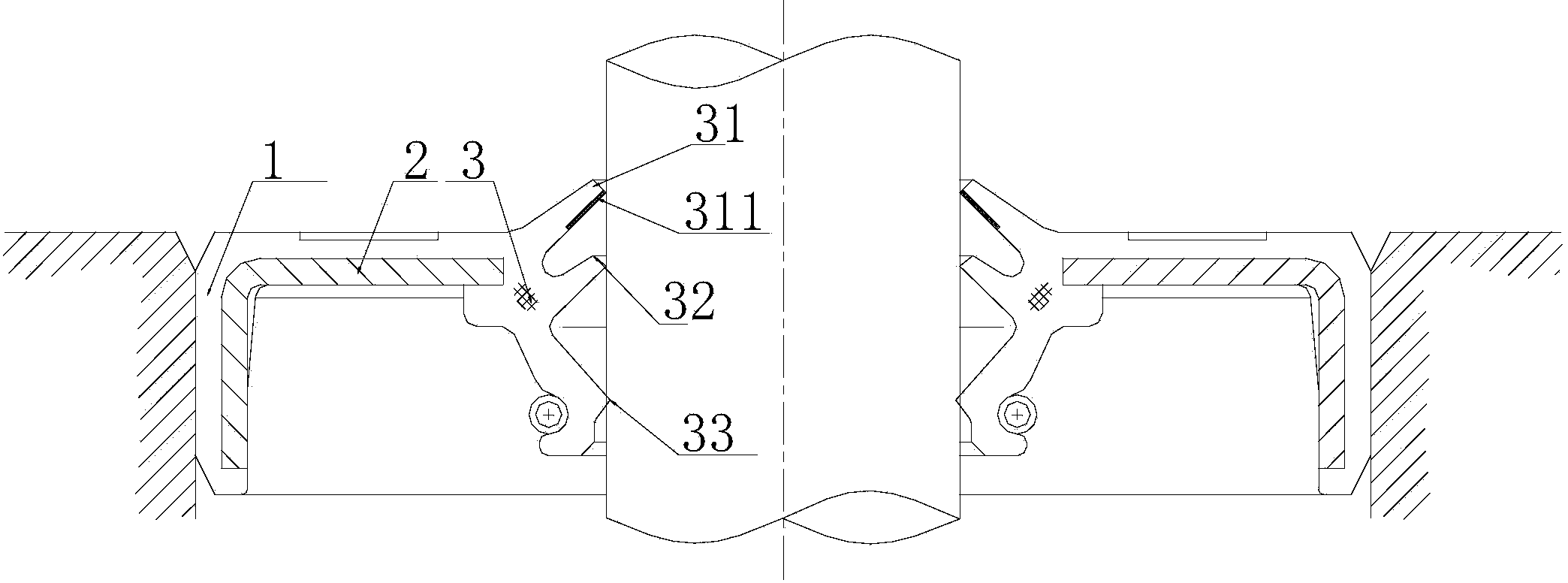

[0024] Such as figure 2 As shown, the sealing ring of the long-lasting washing machine includes an outer sealing part 1, a support ring 2 and an inner sealing part 3. The outer sealing part 1 cooperates with the mounting seat hole to realize the installation of the sealing ring and the sealing of the mounting seat hole. The support ring 2 is set Between the outer sealing part 1 and the inner sealing part 3, it plays the role of connecting the outer sealing part 1 and the inner sealing part 3. The inner sealing part 3 cooperates with the dehydration shaft to realize the sealing of the dehydration shaft, preventing the washing water from being static and running. Leakage occurs at the shaft of the dehydration shaft.

[0025] The inner sealing part 3 includes three sealing lips, namely the first sealing lip 31, the second sealing lip 32 and the third sealing lip 33, the first sealing lip 31 acts as the main seal function, the second sealing lip 32 is located between the first s...

Embodiment 2

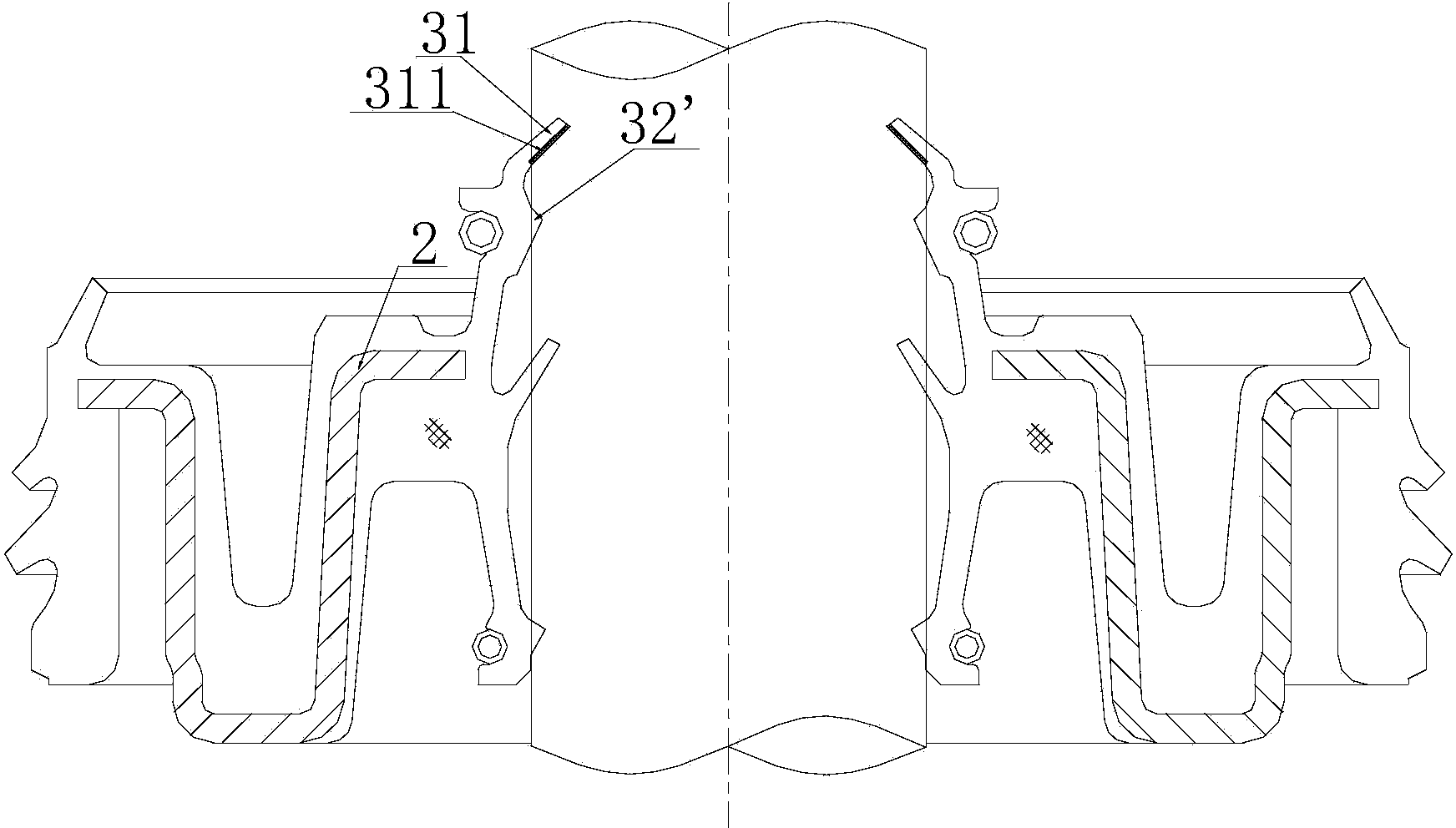

[0028] The difference with embodiment 1 is: as image 3 As shown, the support ring 2 is U-shaped, and the overall elasticity of the sealing ring and the followability with the rotating shaft can be improved by arranging the U-shaped support ring. The first sealing lip 31 plays the main sealing role, and there is a fourth sealing lip 32' between the first sealing lip 31 and the second sealing lip 32, and the fourth sealing lip 32' A spring is provided on the outer side of the annular ring, and the spring provides a holding force for the fourth sealing lip 32', thus enhancing the sealing effect. The space between the first sealing lip 31 and the fourth sealing lip 32' is narrow, and lithium-based grease cannot be filled, so a sheet 311 made of modified PTFE is installed at the first sealing lip 31, and the The low friction and self-lubricating properties reduce the wear of the lip and improve its sealing stability during long-term use. The sealing ring is mainly used in the cl...

Embodiment 3

[0031] The difference with embodiment 1 is: as Figure 4 As shown, the first sealing lip 31 is made of a high-strength modified PTFE annular sheet with a thickness of 0.7-1 mm, and is integrated with the sealing ring through vulcanization. The first sealing lip 31 is formed with the dehydration shaft A tape of a certain width is sealed. During the washing process, there are often a large number of metal objects or sharp objects, which can adversely affect the first sealing lip. Due to the low strength of the rubber material, it is easy to be damaged by foreign matter, resulting in seal failure, while the strength of modified PTFE is higher than that of rubber material, so it can provide stronger resistance to foreign matter damage during washing. In order to improve the resistance to these foreign matters, at the same time, due to the low friction, self-lubricating properties of the modified PTFE and the use of belt seals, the sealing effect of its long-term use is guaranteed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com