High-temperature-resistant and high-humidity-resistant self-lubricating polyketone composition and application thereof

A self-lubricating, high-heat-resistant technology, applied in the field of self-lubricating materials, can solve the problems of inability to combine polyketone matrix, inability to exert wear resistance, instability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

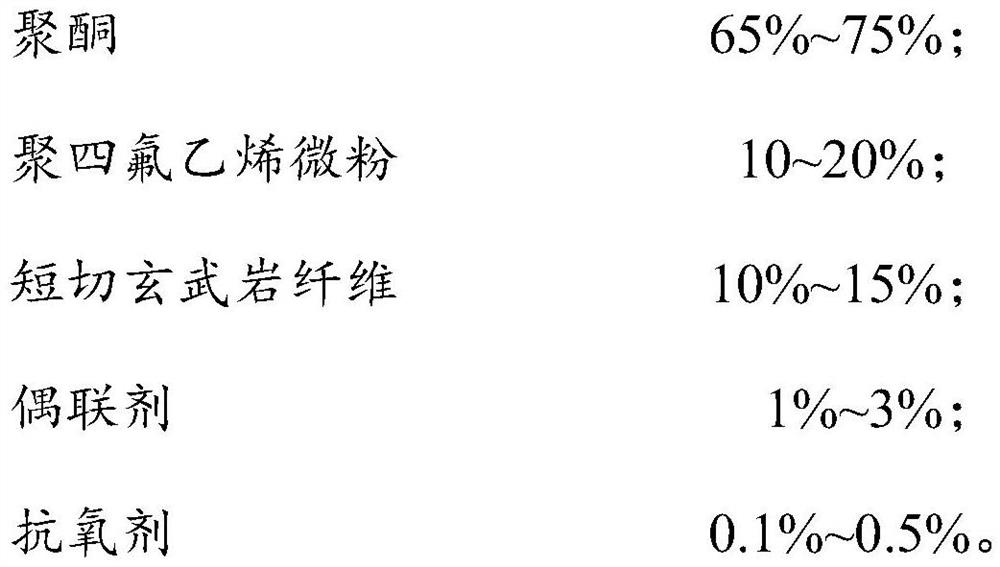

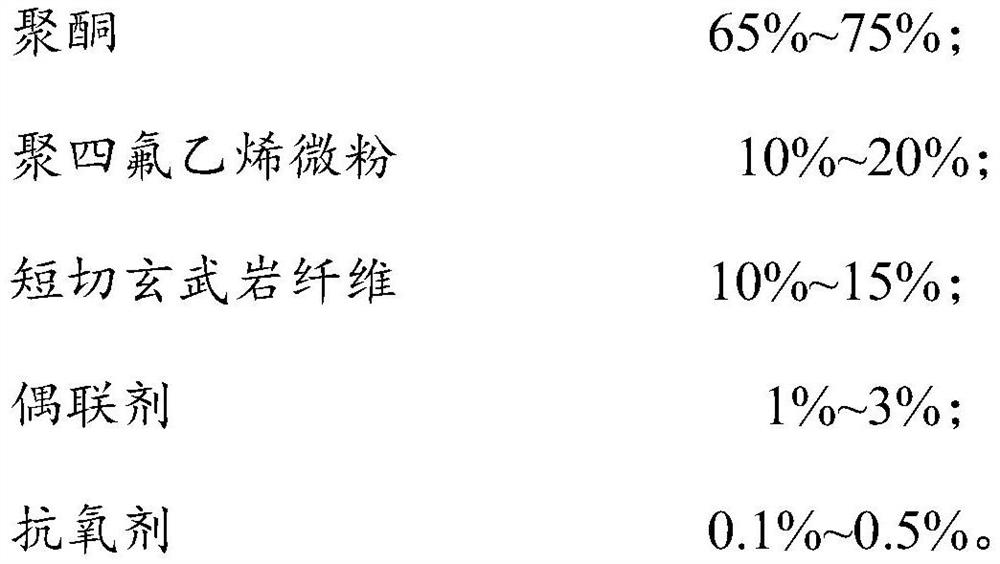

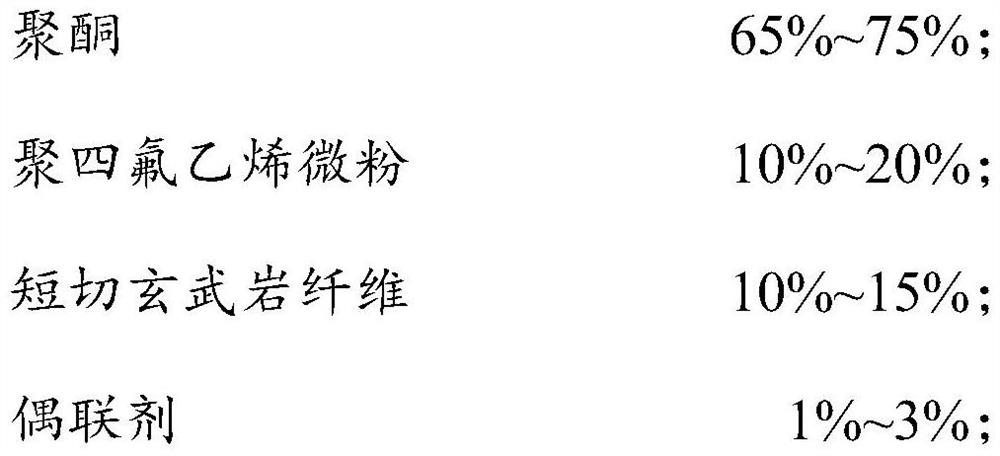

[0053] In the second aspect, the present invention provides a high heat and high humidity self-lubricating polyketone masterbatch obtained by the following preparation method:

[0054] Prepare the above-mentioned high heat-resistant and high-humidity self-lubricating polyketone composition;

[0055] Modify part of the coupling agent on the surface of chopped basalt fiber to obtain modified fiber;

[0056] Mix anhydrous polyketone resin, remaining coupling agent, antioxidant, and polytetrafluoroethylene micropowder, and add modified fiber through side feeding to obtain a premix;

[0057] Melt and blend the premix at 220-260°C, and finally extrude and granulate to obtain high heat and high humidity self-lubricating polyketone masterbatch.

[0058] In the third aspect, the present invention provides a high heat and high humidity resistant self-lubricating workpiece prepared from the above high heat and high humidity self-lubricating polyketone composition, in particular, the hig...

Embodiment 1

[0061] The high heat-resistant and high-humidity self-lubricating polyketone composition provided in this example includes the following components by weight percentage: polyketone 73%, polytetrafluoroethylene micropowder 12%, chopped basalt fiber 12%, coupling agent 2.5% %, antioxidant 0.5%.

[0062] The preparation method of the high heat and high humidity self-lubricating polyketone masterbatch provided in this embodiment comprises the following steps:

[0063] (1) Prepare the high heat and high humidity self-lubricating polyketone composition according to the following weight percentage: 73% polyketone, 12% polytetrafluoroethylene micropowder, 12% chopped basalt fiber, 2.5% coupling agent, 0.5% antioxidant .

[0064] (2) Surface modification treatment of chopped basalt fiber: add chopped basalt fiber to the ethanol solution of KH550 coupling agent, the mass percentage concentration of KH550 coupling agent is 3%, and fully stir in a high-speed shear disperser for 30min , ...

Embodiment 2

[0069] The high heat-resistant and high-humidity self-lubricating polyketone composition provided in this example is composed of the following components by weight percentage: 70% polyketone, 15% polytetrafluoroethylene micropowder, 12% chopped basalt fiber, and a coupling agent 2.5%, antioxidant 0.5%.

[0070] The preparation method of the high heat and high humidity self-lubricating polyketone masterbatch provided in this embodiment comprises the following steps:

[0071] (1) Prepare the high heat and high humidity self-lubricating polyketone composition according to the following weight percentage: 70% polyketone, 15% polytetrafluoroethylene micropowder, 12% chopped basalt fiber, 2.5% coupling agent, 0.5% antioxidant ;

[0072] (2) Surface modification treatment of chopped basalt fiber: add chopped basalt fiber to the ethanol solution of KH550 coupling agent, the mass percent concentration of KH550 coupling agent is 2%, and fully stir in a high-speed shear disperser for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com