Oil-containing nylon roller envelope for warp knitting machine cam swing arm transmission mechanism and its production method

A technology of transmission mechanism and cam pendulum, which is applied in warp knitting, mechanical equipment, textiles and papermaking, etc., can solve the problems of low service life and easy wear and tear, and achieve high mechanical strength, wear-resistant cost, and simple and easy manufacturing method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a, 85 kg of caprolactam is placed in the reactor and melted at a temperature of 50°C;

[0021] B, add 2 kilograms of sodium hydroxide additives and 5 kilograms of mineral oils (can be conventional lubricating grease) to above-mentioned fully molten caprolactam, stir to obtain casting raw material;

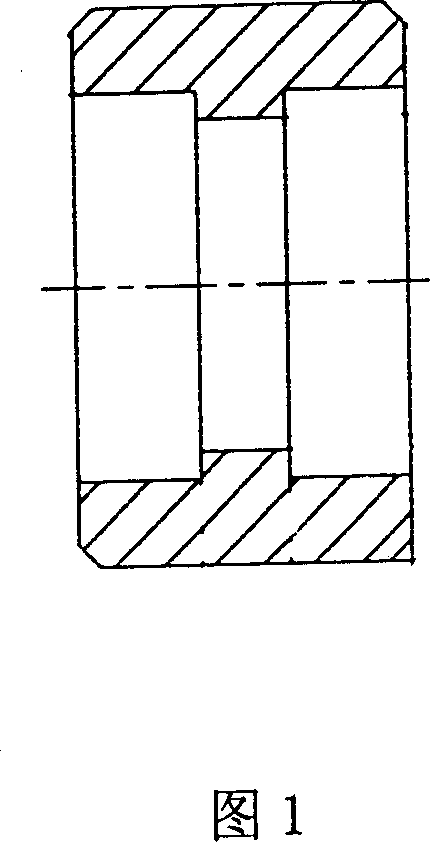

[0022] c. Pour the above-mentioned uniformly stirred casting raw materials into the mold and heat to 200°C, and after natural cooling, the blank as shown in Figure 1 is obtained;

[0023] d. Machining the above-mentioned blanks to meet the requirements of the drawings to obtain the finished product of the present invention.

Embodiment 2

[0025] a, 90 kg of caprolactam is placed in the reactor and melted at a temperature of 100°C;

[0026] B, add 2 kilograms of sodium hydroxide additives and 8 kilograms of mineral oils (such as butter) to above-mentioned fully molten caprolactam, stir to obtain casting raw material;

[0027] c. Pour the above-mentioned uniformly stirred casting raw materials into the mold and heat to 250°C, and after natural cooling, the blank as shown in Figure 1 is obtained;

[0028] d. Machining the above-mentioned blanks to meet the requirements of the drawings to obtain the finished product of the present invention.

Embodiment 3

[0030] a, 93 kg of caprolactam is placed in the reactor and melted at a temperature of 120°C;

[0031] B, add 5 kilograms of sodium hydroxide additives and 10 kilograms of mineral oils (as lithium-based lubricating oil) to above-mentioned fully molten caprolactam, stir to obtain casting raw material;

[0032] c. Pour the above-mentioned uniformly stirred casting raw materials into the mold and heat to 250°C, and after natural cooling, the blank as shown in Figure 1 is obtained;

[0033] d. Machining the above-mentioned blanks to meet the requirements of the drawings to obtain the finished product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com