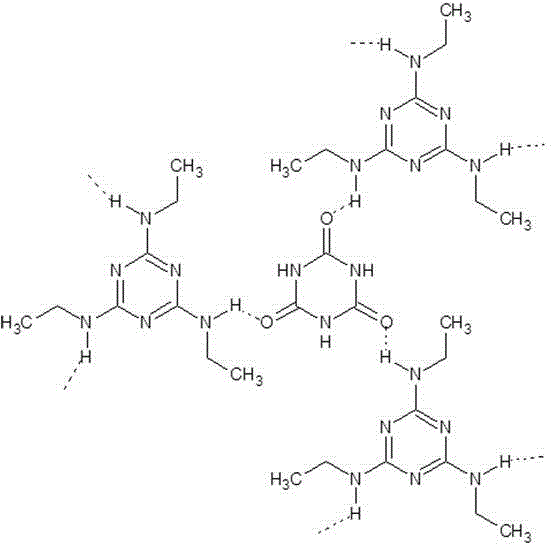

Method for preparing microcapsule-coated ammonium polyphosphate through in-situ polymerization molecular self-assembly

A technology for coating ammonium polyphosphate and ammonium polyphosphate, which is applied in the field of materials, can solve the problems of reduced water solubility of ammonium polyphosphate, deteriorated heat transfer of the reaction kettle, and decreased stability, so as to reduce water solubility, facilitate industrial production, The effect of surface polarity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

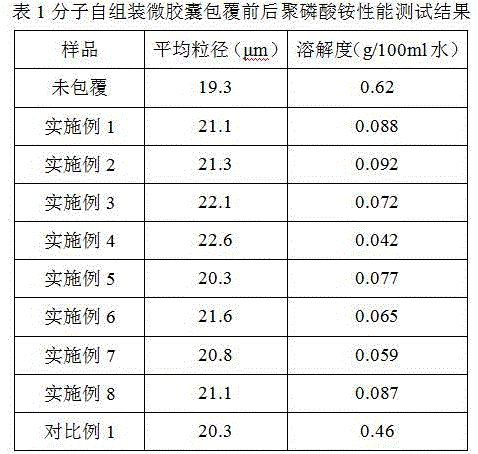

Embodiment 1

[0033] In a 2L reaction kettle equipped with a stirrer, a thermometer, and a condensing reflux device, add 45g of melamine and 45g of formaldehyde (37wt% formaldehyde aqueous solution, the same below), adjust the pH to 8-9 with sodium bicarbonate, and raise the temperature to 70°C to react 0.5 -1h, after the reaction, cool down to 30°C, then add 180g ammonium polyphosphate and 540g deionized water, stir for 1-2h, then add 45g cyanuric acid, rise to 40°C, stir for 3-4h, filter and dry after reaction, Obtain 268g molecular self-assembled microcapsule-coated ammonium polyphosphate.

Embodiment 2

[0035] Add 36g melamine and 36g formaldehyde to a 2L reactor equipped with a stirrer, thermometer and condensing reflux device, adjust the pH to 8-9, raise the temperature to 70°C for 0.5-1h, cool down to 30°C after the reaction, and then add 180g Ammonium polyphosphate and 720g deionized water were stirred for 1-2 hours, then 36g of cyanuric acid was added, the temperature was raised to 60°C and the reaction was stirred for 3-4 hours. After the reaction, it was filtered and dried to obtain 248.6g of molecular self-assembled microcapsule-coated ammonium polyphosphate .

Embodiment 3

[0037]Add 30g melamine and 30g formaldehyde to a 2L reaction kettle equipped with a stirrer, a thermometer and a condensing reflux device, adjust the pH to 8-9, raise the temperature to 70°C for 0.5-1h, cool down to 30°C after the reaction, and then add 180g ammonium polyphosphate and 900g deionized water, stirred for 1-2 hours, then added 30g of cyanuric acid, heated to 60°C and stirred for 3-4 hours, filtered and dried after reaction to obtain 233.6g molecular self-assembled microcapsule-coated polyphosphoric acid Ammonium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com