Inorganic fire retardant paper and preparation method and application thereof

A technology of inorganic flame-resistant paper and inorganic filler, which is applied in spinning solution preparation, textile and papermaking, fiber processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

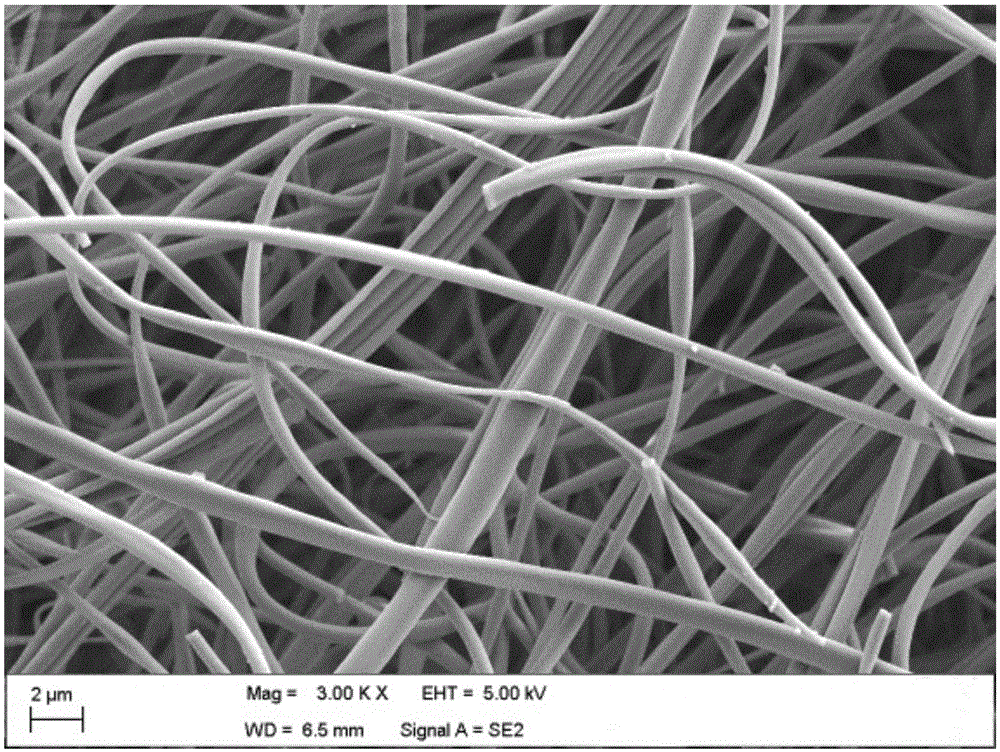

[0032] In this example, SiO 2 Nanofibers prepared by sol electrospinning as the main material of inorganic flame-resistant paper, TiO 2 As a paper filler, the present invention is further illustrated by examples, but the scope of protection of this patent should not be limited by this. All other inorganic glass precursor sols that can be used for spinning and can be treated by subsequent soaking-drying-compacting-heat treatment Silicate electrospun fiber nonwoven membranes for filling materials such as SiO 2 , CaO, Al 2 o 3 , ZrO 2 etc. and their mixtures are suitable for the inorganic flame-resistant paper disclosed in the present invention.

[0033] The preparation process of the inorganic flame-resistant paper of the present embodiment is as follows:

[0034] Step 1. With ethyl orthosilicate (TEOS), absolute ethanol (EtOH), water (H 2 O), acids (including hydrochloric acid (HCl), nitric acid (HNO 3 ), sulfuric acid (H 2 SO 4 ), acetic acid) as raw materials, and sy...

Embodiment 2-25

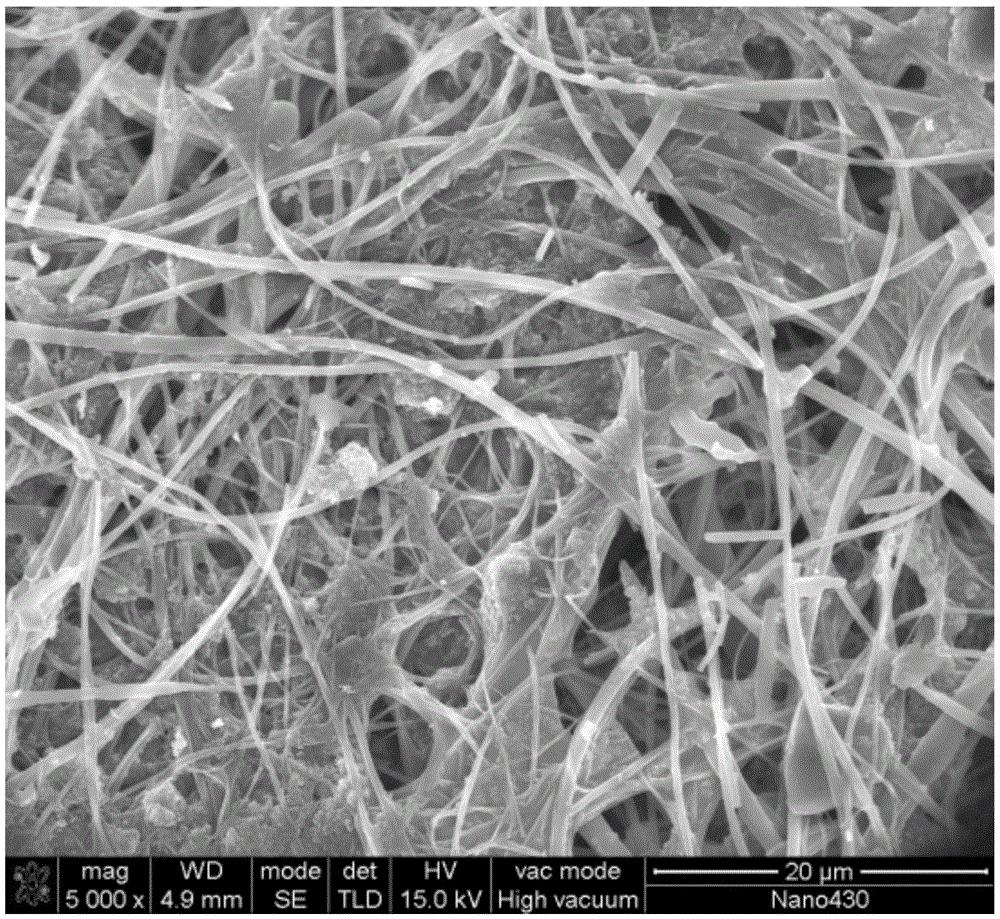

[0048] The silicate electrospun nanofiber that the present invention relates to, its composition is SiO 2 As the main body, Al can also be added 2 o 3 , ZrO 2 and other components to improve the mechanical and thermal properties of the fiber. Illustrate below through embodiment 2-25. The main feature of embodiment 2-25 is to adjust the molar ratio of each added raw material in the spinning sol, as shown in table 2:

[0049] The mass ratio of each raw material in the spinning sol of the embodiment 2-25 of table 2

[0050]

[0051]

[0052] The operation steps are as follows:

[0053] Step 1. Use tetraethyl orthosilicate (TEOS), aluminum nitrate pentahydrate (Al(NO 3 ) 3 ·5H 2 O), zirconium nitrate pentahydrate (Zr(NO 3 ) 2 ·5H 2 O), ethanol (EtOH), water (H 2 O), hydrochloric acid (HCl), as raw materials, synthesize spinnable sol by sol-gel technology. The above raw materials were uniformly mixed according to the proportion listed in Table 1, and then a spinn...

PUM

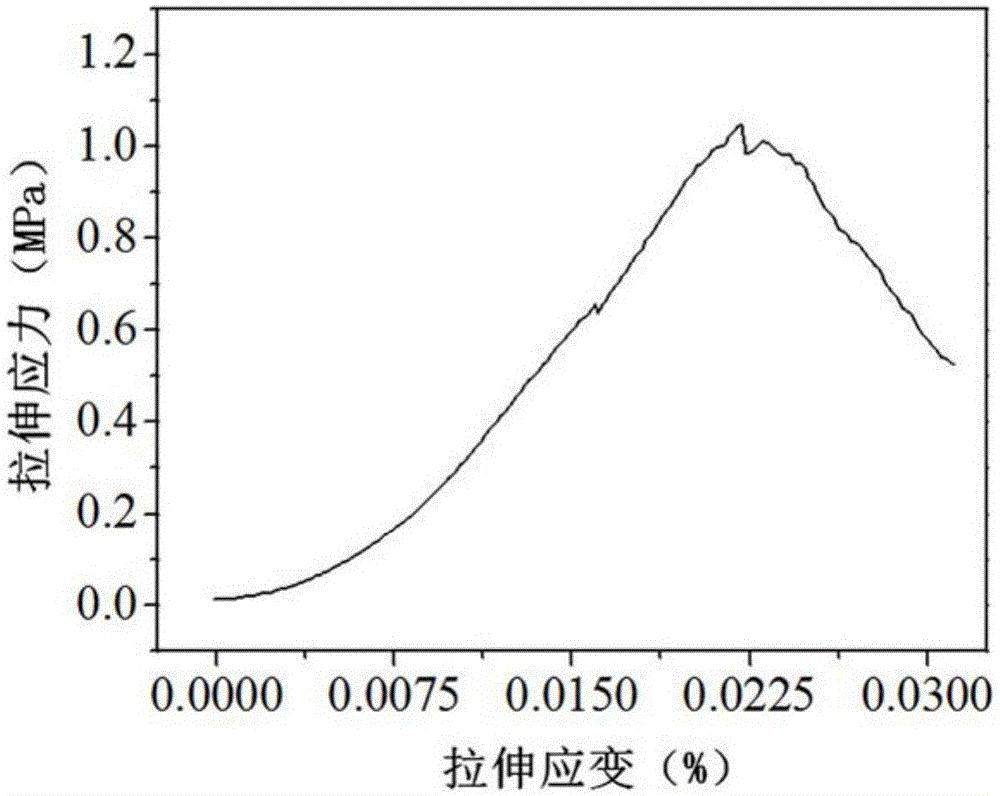

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com