Superfine nickel fiber and preparation method thereof

A technology of nickel fiber and nickel salt, which is applied in the field of new one-dimensional magnetic materials and new microwave absorbing materials, can solve the problems of restricting the application research of ultrafine nickel fibers, unfavorable industrial scale-up preparation, complicated purification process, etc., and achieve large-scale and various The effects of anisotropy, cheap raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

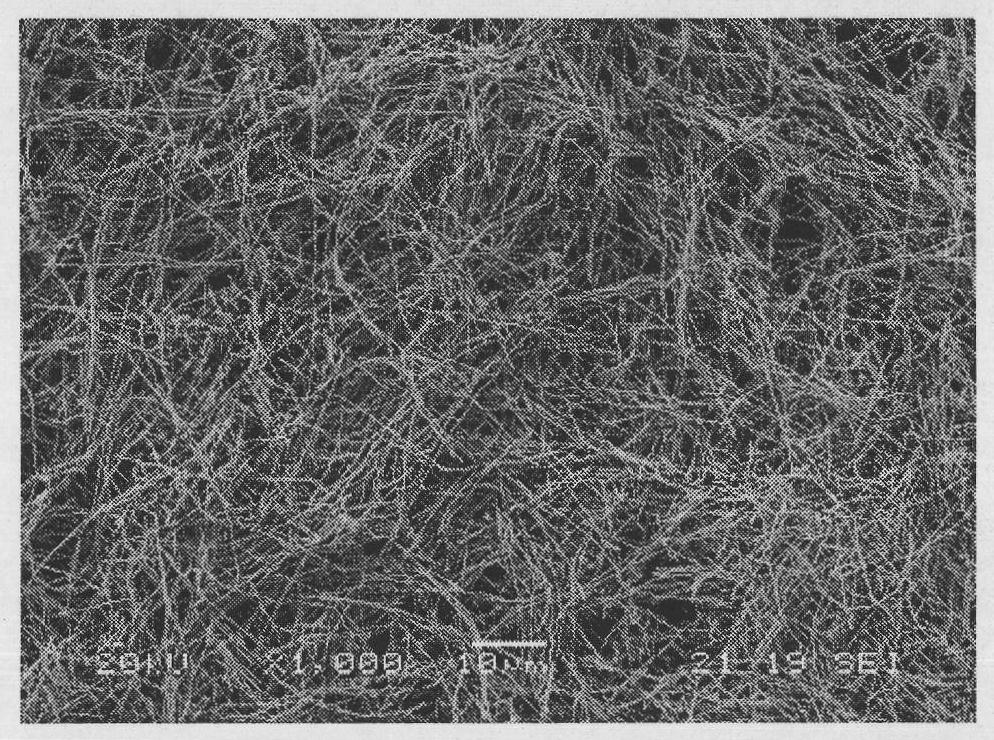

Embodiment 1

[0051] Nickel chloride hexahydrate NiCl 2 ·6H 2 O was completely dissolved in 50ml ethylene glycol, NiCl 2 ·6H 2 The concentration of O is 0.01M, add 1ml of 80wt% H to the above solution 4 N 2 ·H 2 O solution and 0.3g NaOH particles were mixed thoroughly. After mixing, the solution was slowly heated to 55°C and kept at this temperature for 15 minutes, and then the reactant was naturally cooled to room temperature. The black product is separated magnetically, washed three times with absolute ethanol, and dried in vacuum to obtain pure ultrafine nickel fibers.

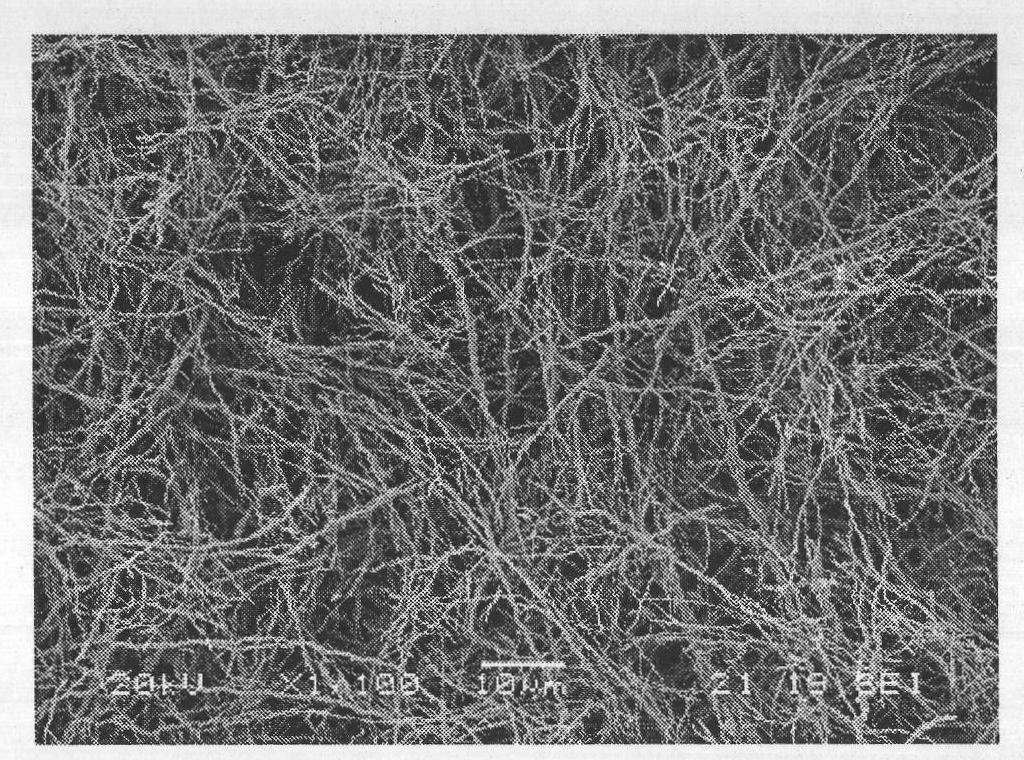

Embodiment 2

[0053] Nickel chloride hexahydrate NiCl2 ·6H 2 O was completely dissolved in 50ml ethylene glycol, NiCl 2 ·6H 2 The concentration of O is 0.02M, add 3ml of 80wt% H to the above solution 4 N 2 ·H 2 O solution and 0.40g NaOH particles were mixed thoroughly. After mixing, the solution was slowly heated to 55°C and kept at this temperature for 20 minutes, and then the reactant was naturally cooled to room temperature. The black product is separated by suction filtration, washed three times with absolute ethanol, and dried in vacuum to obtain pure ultrafine nickel fibers.

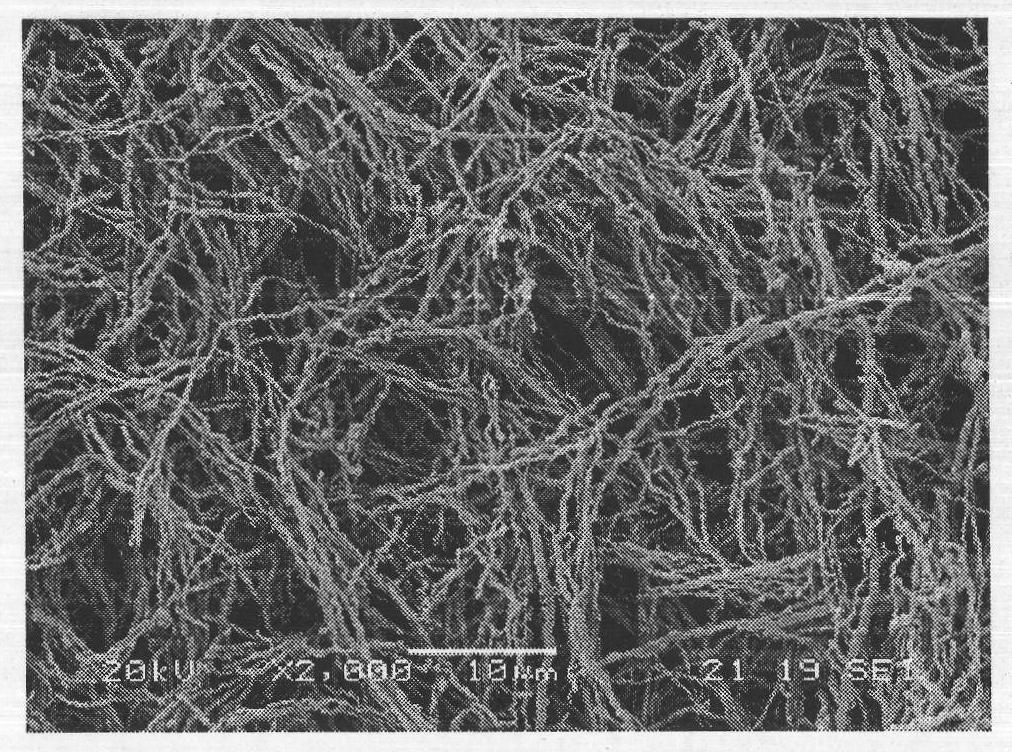

Embodiment 3

[0055] Nickel chloride hexahydrate NiCl 2 ·6H 2 O was completely dissolved in 50ml ethylene glycol, NiCl 2 ·6H 2 The concentration of O is 0.05M, add 3ml of 80wt% H to the above solution 4 N 2 ·H 2 O solution and 1.5g NaOH particles were mixed thoroughly. After mixing, the solution was slowly heated to 55°C and kept at this temperature for 30 minutes, and then the reactant was naturally cooled to room temperature. The black product is separated magnetically, washed three times with absolute ethanol, and dried in vacuum to obtain pure ultrafine nickel fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com