Lightweight aluminum bamboo/carbon compound material, and preparation method and application thereof

A carbon composite material, lightweight technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of limited use of composite materials, blank period, etc. Good noise cancelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

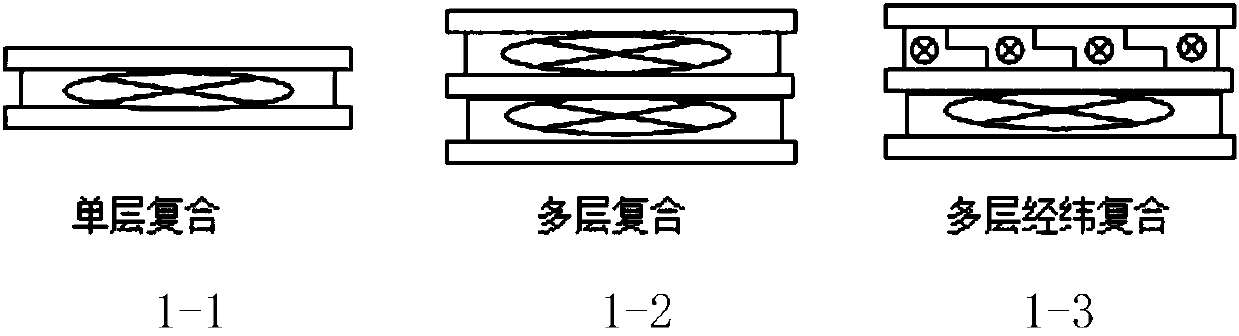

[0022] According to the single-layer composite method (such as Picture 1-1 As shown), an aluminum plate with a thickness of 3 mm and a bamboo plate with a thickness of 5 mm are rolled together in a vise and then placed in a vacuum resistance furnace for sintering.

[0023] The sintering system is: the pressure of the vacuum furnace is 180Pa; the sintering temperature is 800℃; the temperature is kept for 3 hours; and then it is naturally cooled to room temperature.

[0024] After taking out the sintered aluminum-bamboo (carbon) composite material, use a universal testing machine to test the mechanical properties. The result shows: the ultimate tensile strength σ b =315MPa; tensile yield strength σ 0.2 =261MPa; elongation δ 5 (%)=13; Hardness HB=54; Compared with aluminum alloy of the same volume, the mass is reduced by 14%.

Embodiment 2

[0026] According to the double-layer composite method (such as figure 1 -2), the aluminum plate with a thickness of 3mm and a bamboo plate with a thickness of 5mm are rolled together in a vise and then placed in a vacuum resistance furnace for sintering.

[0027] The sintering system is: the pressure of the vacuum furnace is 150Pa; the sintering temperature is 700°C; the temperature is kept for 5 hours; then it is naturally cooled to room temperature.

[0028] After taking out the sintered aluminum-bamboo (carbon) composite material, use a universal testing machine to test the mechanical properties. The result shows: the ultimate tensile strength σ b =321MPa; tensile yield strength σ 0.2 =257MPa; elongation δ 5 (%)=11; Hardness HB=45; Compared with aluminum alloy of the same volume, the mass is reduced by 18%.

Embodiment 3

[0030] According to the longitude and weft compound method (such as figure 1 -3), the aluminum plate with a thickness of 2mm and a bamboo plate with a thickness of 4mm are rolled together in a vise and then placed in a vacuum resistance furnace for sintering.

[0031] The sintering system is: the pressure of the vacuum furnace is 160 Pa; the sintering temperature is 850°C; the temperature is kept for 4 hours; then it is naturally cooled to room temperature.

[0032] After taking out the sintered aluminum-bamboo (carbon) composite material, use a universal testing machine to test the mechanical properties. The result shows: the ultimate tensile strength σ b =311MPa; tensile yield strength σ 0.2 =251MPa; elongation δ 5 (%)=11; Hardness HB=48; Compared with aluminum alloy of the same volume, the mass is reduced by 17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com