Three-blocking and two-injecting gas extraction hole sealing method

A three-blocking, two-injection, gas technology, which is applied in the direction of gas discharge, earthwork drilling, sealing/isolation, etc., can solve the problem of unsatisfactory gas drainage effect, excessive gas leakage from coal walls and orifices, and unsatisfactory sealing effect and other issues to achieve the effect of reducing scrap rate, improving drainage effect and saving economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

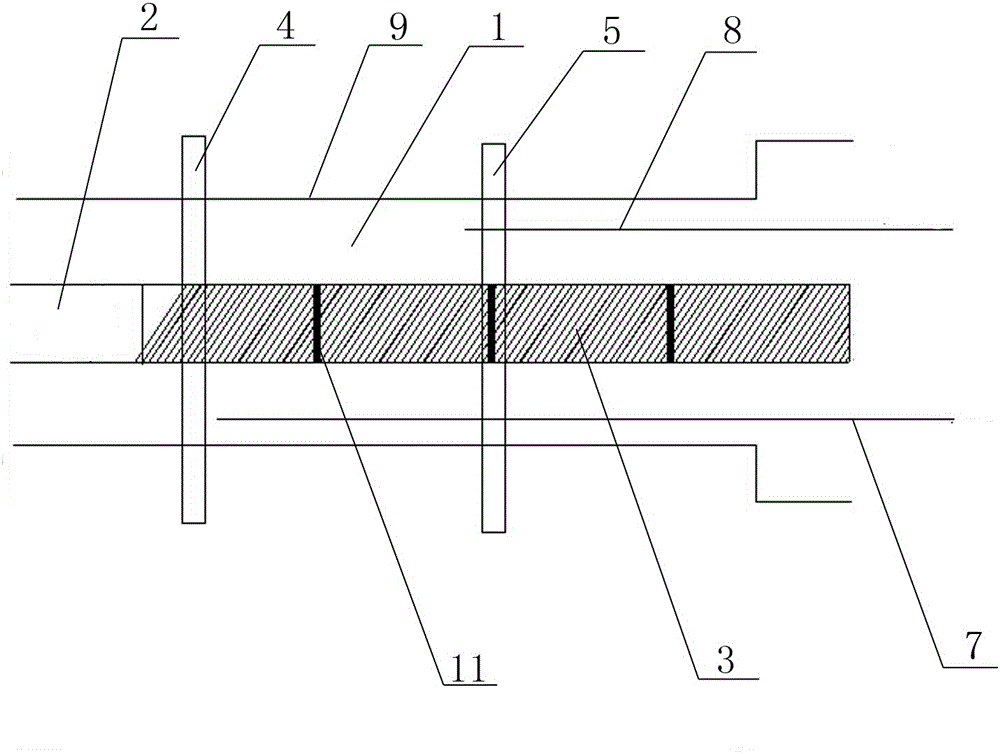

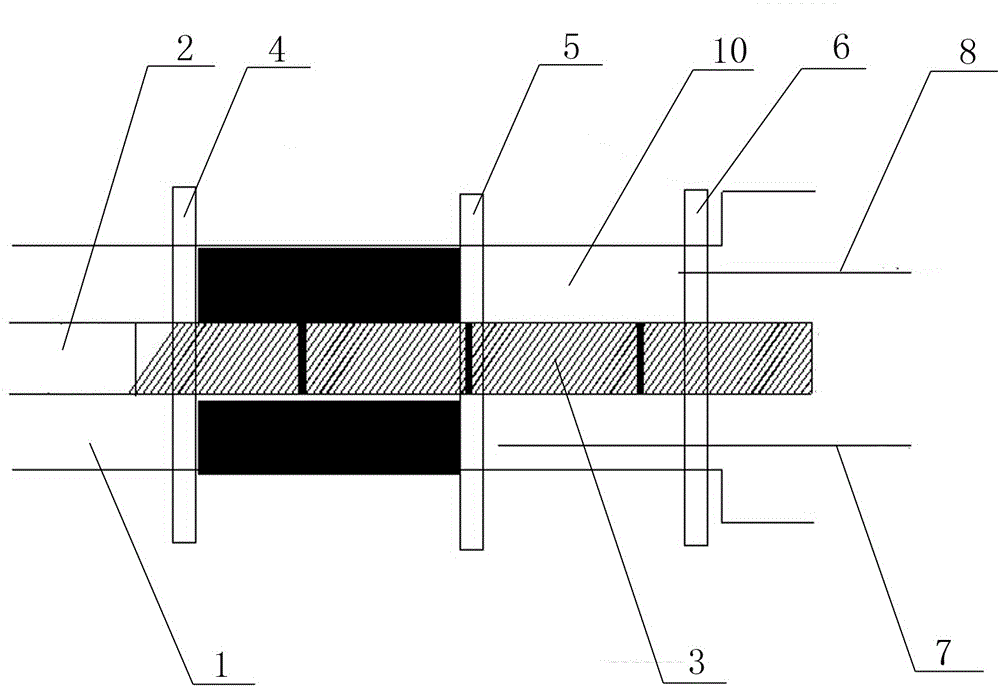

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] A "three-blocking and two-injection" gas pumping anti-hole sealing method, including hole washing, plugging, pre-sealing, pressure measurement before grouting, first half of grouting under pressure, second half of grouting under pressure, pasting holes . After the hole is formed, use the returned water in the drill pipe to wash the hole. After the drill pipe is pulled out, the entire drill hole will be filled, and the bag will be used for pre-sealing, and air will be injected for pressure testing. , Use sealing cement to paste the hole.

[0033] Specific steps are as follows:

[0034] (1) wash hole

[0035] After the hole is drilled, because the drillers do not pay attention to the hole washing work, a large amount of coal dust remains in the drill hole. After the hole is pre-sealed, due to the existence of the coal dust, the bag and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com