Closed wound surface curing dressing system

A closed and traumatic technology, applied in the field of medical devices, can solve the problems of no simple anti-suckback design, unstable sealing effect, and restrictions on popularization and application, and achieve the effects of easy collection, low air leakage, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

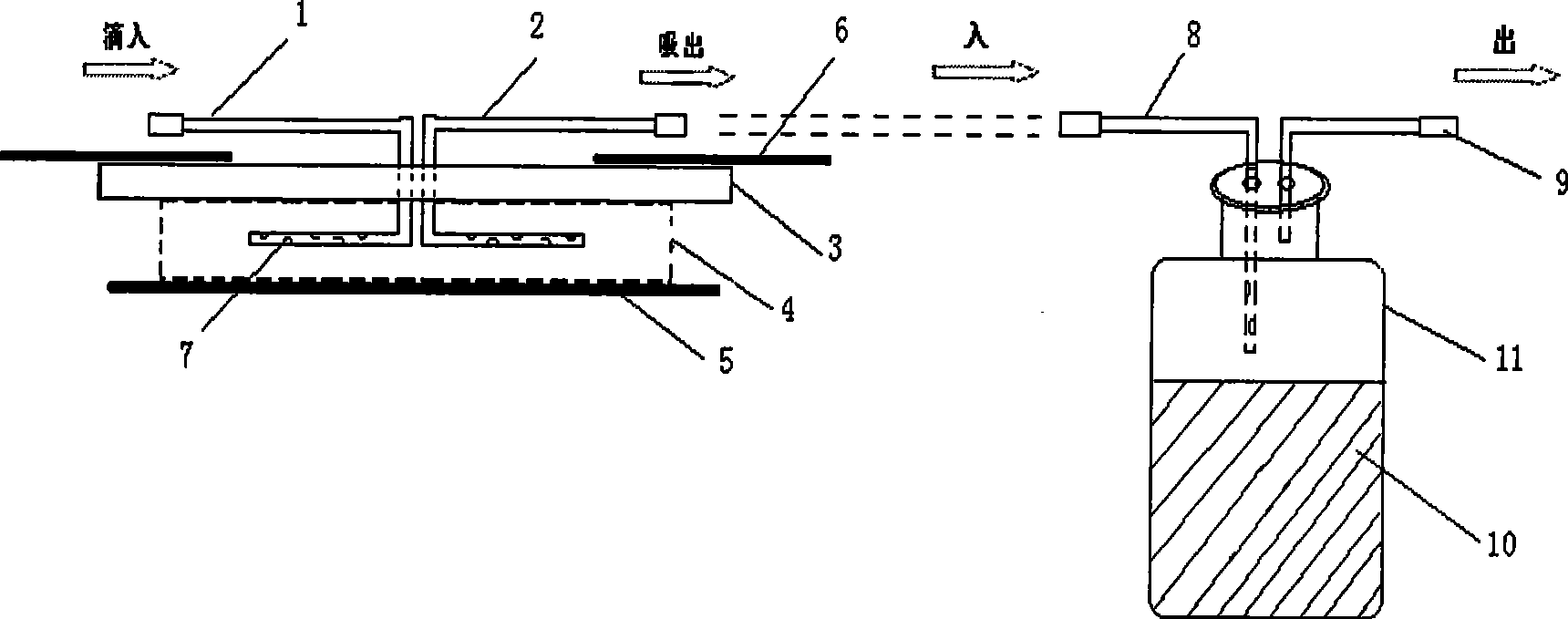

[0015] Referring to the accompanying drawings, the non-stick gauze 5 is provided with a polyurethane sponge 4, the polyurethane sponge 4 is provided with a silicone membrane 3, the infusion tube 1 and the drainage tube 2 pass through the silicone membrane 3 respectively, and the silicone membrane 3 and the periwound skin are used for medical use. The film 6 is pasted and closed, inserted into the polyurethane sponge 4, the drip tube 1 and the drainage tube 2 left in the polyurethane sponge 4 are all provided with side holes 7, the drainage tube 2 is connected with the inlet tube 8 of the drainage bottle 11, and the drainage bottle 11 has a built-in The microporous adsorbent material 10 , the inlet pipe 8 and the outlet pipe 9 lead into the drainage bottle 11 respectively, and the inlet pipe 8 and the outlet pipe 9 leave a distance from the microporous adsorbent material 10 .

[0016] The polyurethane sponge has a thickness of 1.5-2.0 cm and a pore diameter of 400-600 μm. There...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com