Wastewater treatment device and wastewater treatment method for realizing deep wastewater denitrification based on sequencing batch type A/O (Anoxic/Oxic) linkage system

A linkage system, deep denitrification technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as many control parameters and complex operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

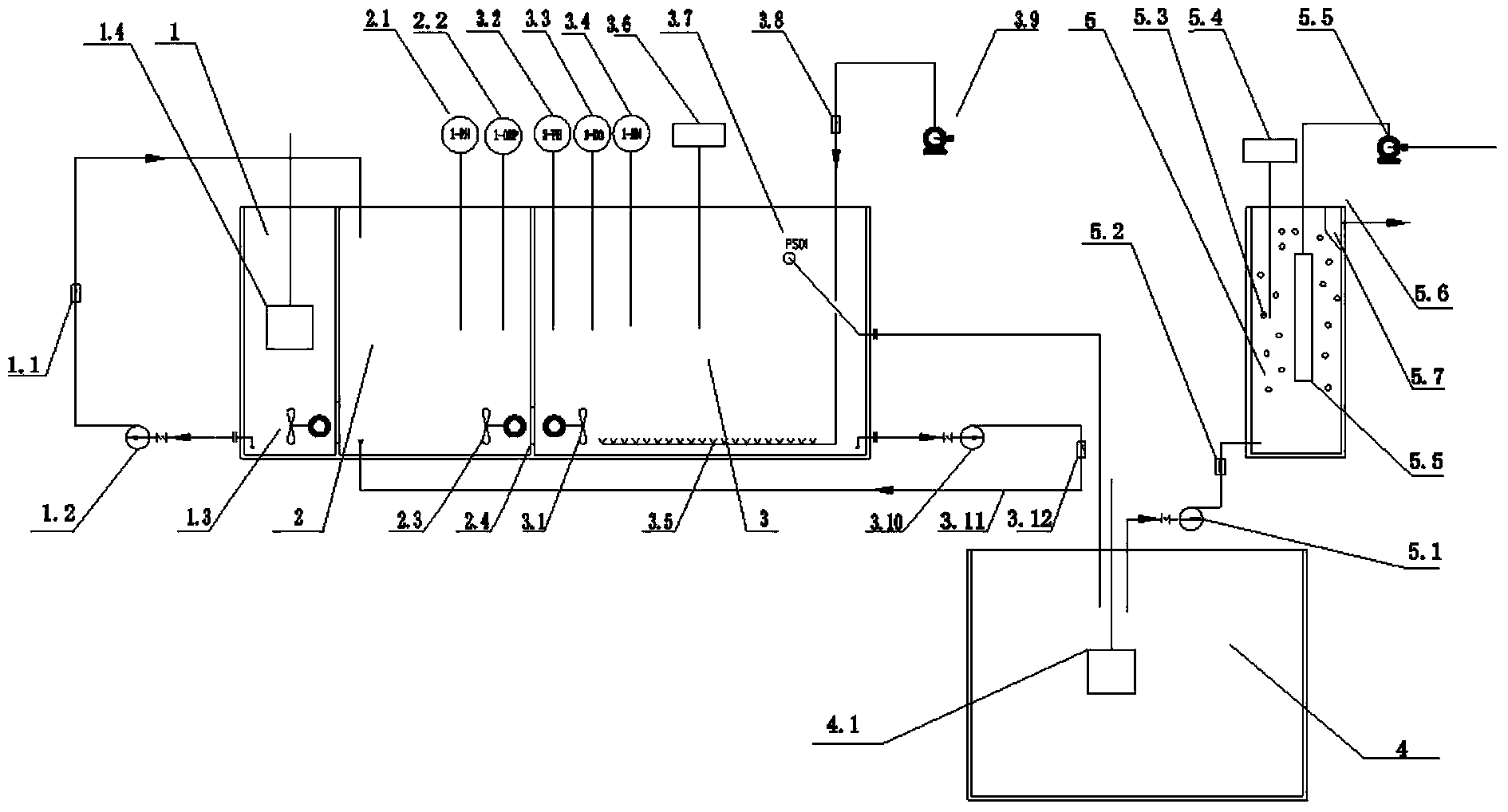

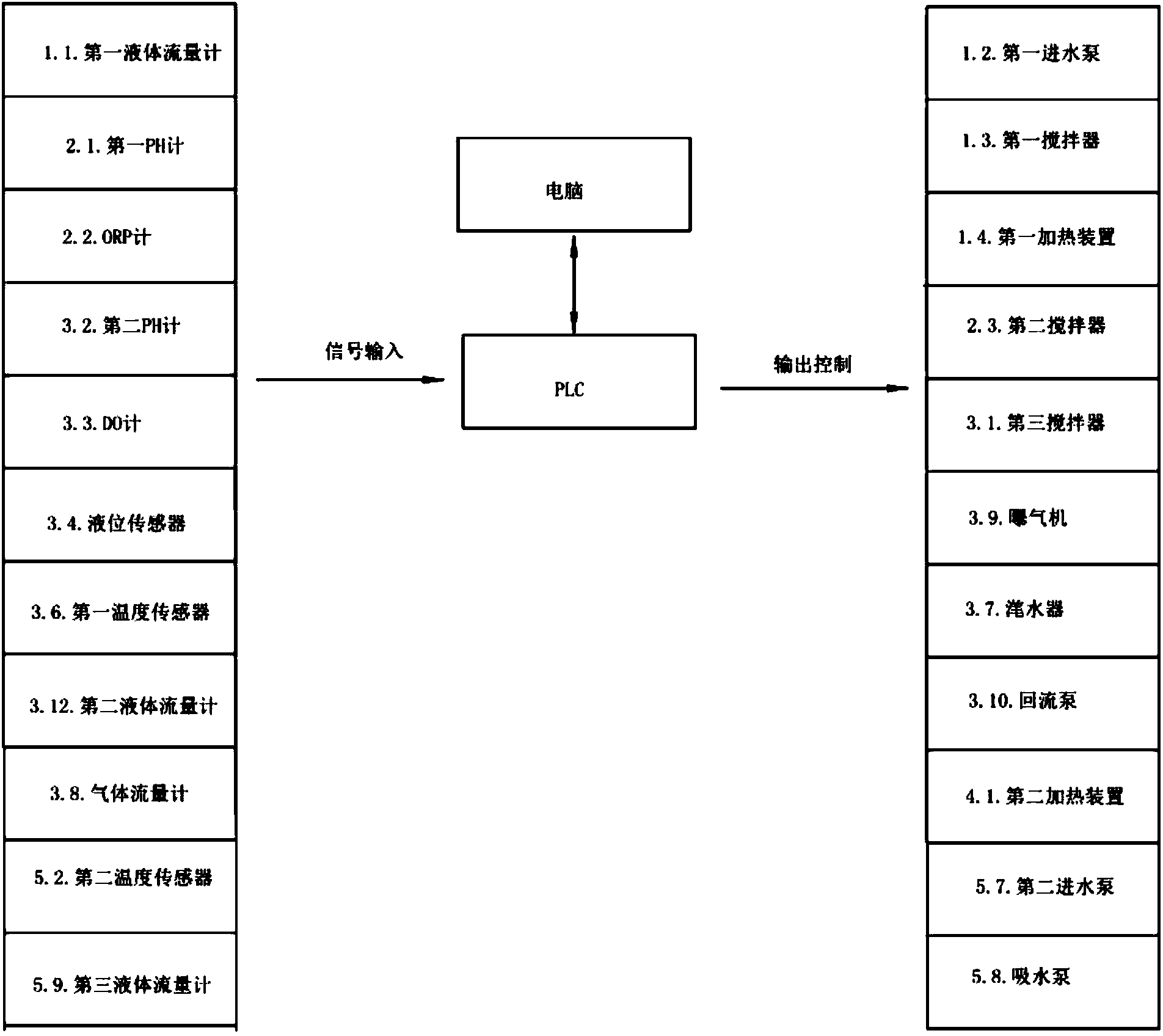

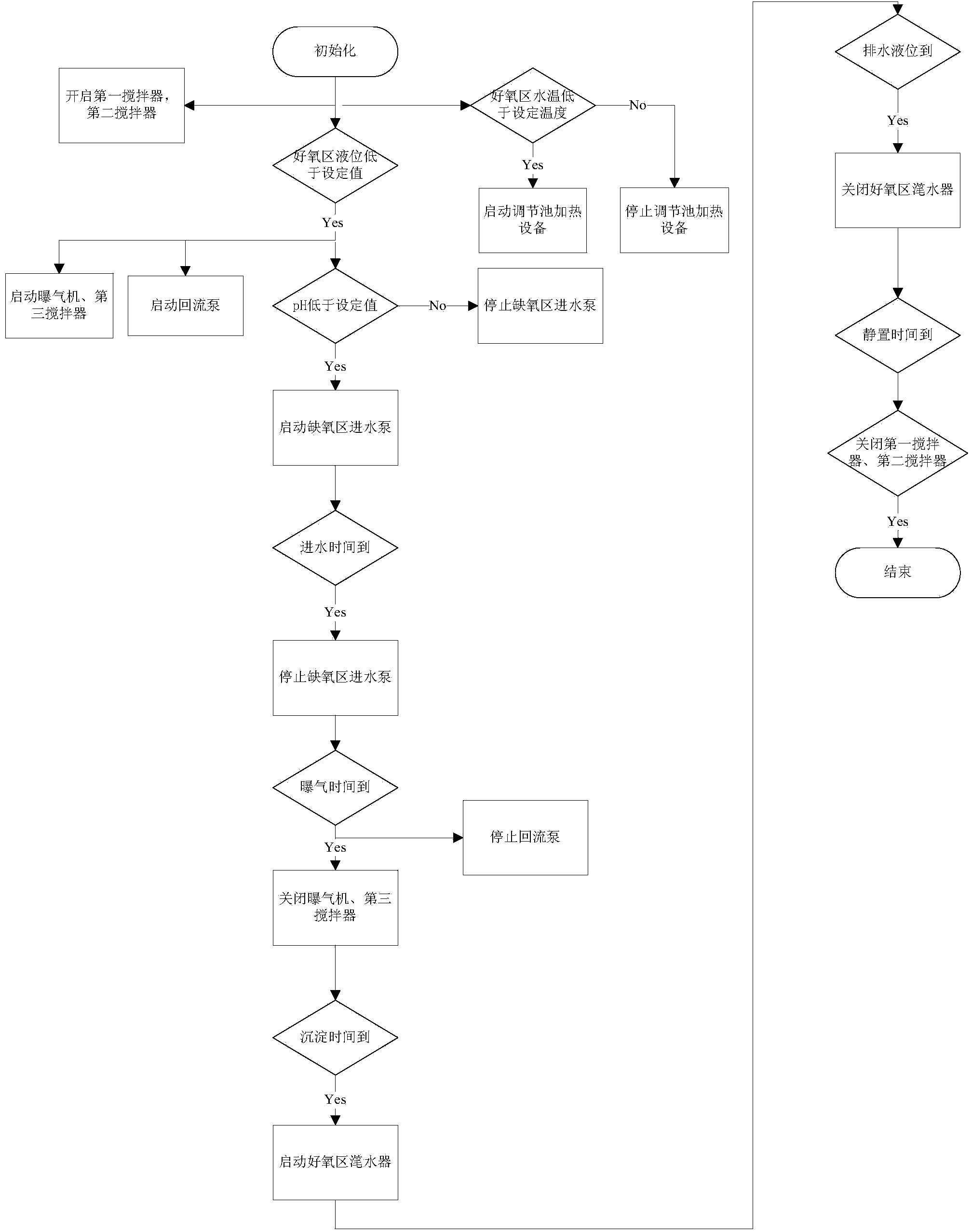

[0077] Such as figure 1 As shown, a wastewater treatment device based on the sequencing batch A / O linkage system to realize the deep denitrification of wastewater is equipped with a regulating tank 1, SBR reaction tanks 2 and 3, an intermediate storage tank 4 and an MBR / MBBR reaction tank 5; Described SBR reaction tank 2,3 comprises SBR reaction tank anoxic zone 2 and SBR reaction tank aerobic zone 3;

[0078] The regulating tank 1 communicates with the anoxic zone 2 of the SBR reaction tank through the first water inlet pump 1.2 and the first liquid flow meter 1.1 in sequence;

[0079] The anoxic zone 2 of the SBR reaction tank communicates with the aerobic zone 3 of the SBR reaction tank through the overflow tank 2.4;

[0080] An aeration pipe 3.5 is provided at the bottom of the aerobic zone 3 of the SBR reaction tank; the aeration pipe 3.5 is connected to the aerator through a gas flow meter;

[0081] The bottom of the aerobic zone 3 of the SBR reaction tank communicates...

Embodiment 2

[0120] The wastewater treatment device based on the sequencing batch A / O linkage system of the present invention to realize the deep denitrification of wastewater, wherein the size of the regulating tank is B×H×L=470×500×440cm, and the total volume is 103,400L. The size of the anoxic zone of the SBR reaction tank is 470×500×440cm, and the effective volume is 100,000L; the size of the aerobic zone of the SBR reaction tank is 470×500×1540cm, and the effective volume is 300,000L; the size of the intermediate storage tank is 470×500 ×1540cm; the size of the MBR / MBBR reaction tank is 175×185×160cm, and the effective volume is 5,000L.

[0121] Take the landfill leachate from Xiaping Solid Waste Landfill in Shenzhen City, its pH is 8.01-8.65, NH 4 + -N concentration up to 1500~3000mg / L, BOD 5 / TN is less than 3 to 5, which is a typical waste water with high ammonia nitrogen concentration and low carbon nitrogen ratio.

[0122] (1) Start the nitrosation reaction:

[0123] 1) Injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com