Method and device for degrading phenol wastewater by heterogeneous catalysis of ozone in high gravity field

A heterogeneous catalysis, heterogeneous catalyst technology, applied in the direction of chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the loss of metal ions, difficulty in separation, secondary pollution of the environment, ozone mass transfer efficiency And other problems, to achieve the effect of reducing processing costs, improving ozone utilization rate, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

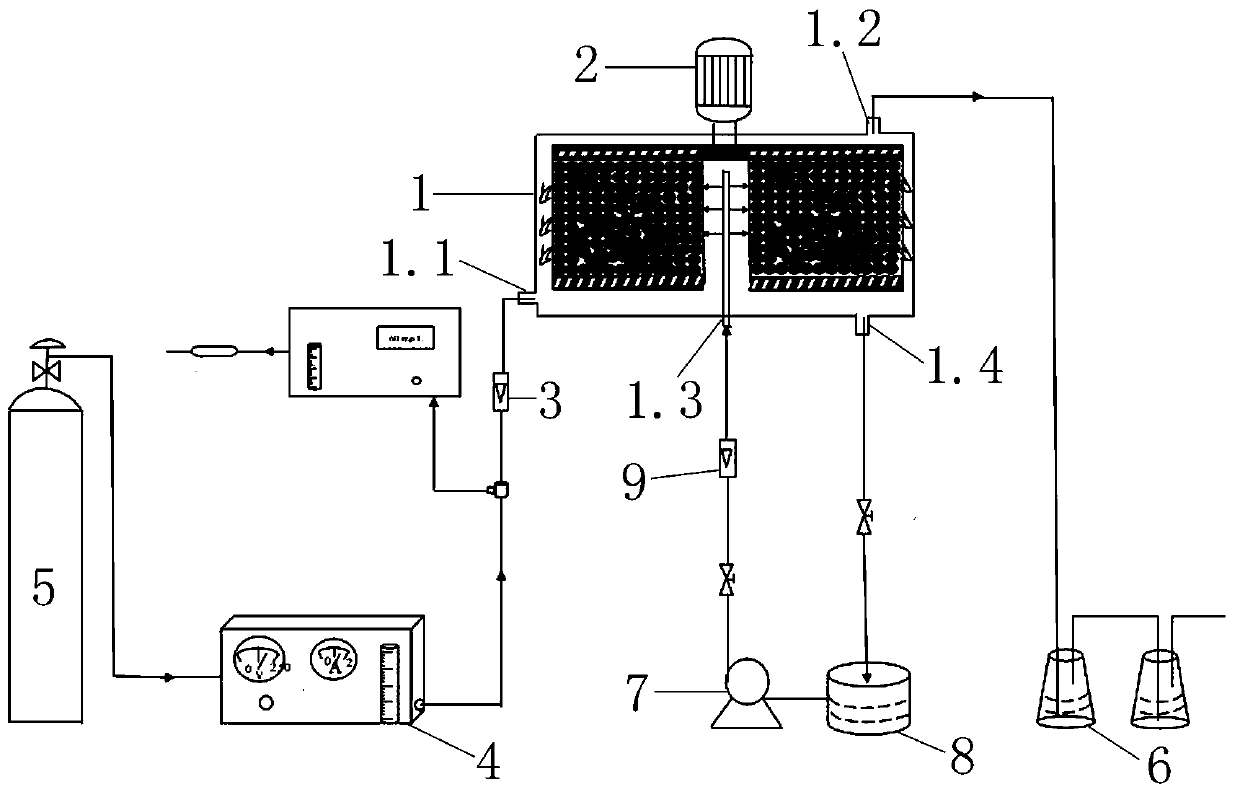

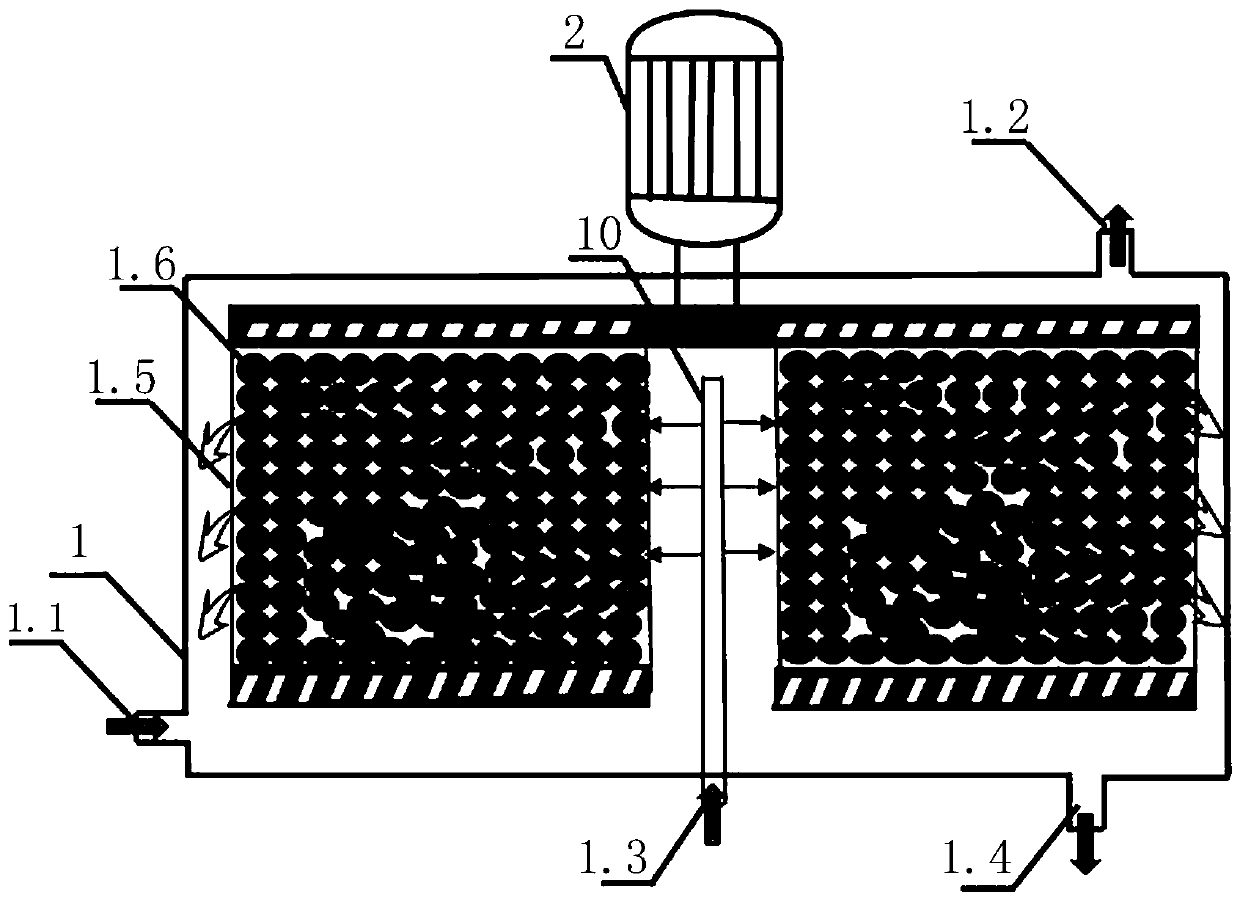

[0033] Example 1: Using figure 1 In the process shown, Fe-Mn-Cu / γ-Al2O3 catalyst is used as filler to degrade phenol wastewater in a high gravity field. The active components Fe: Mn: Cu are 0.2%, 0.2% and 0.8% respectively, the specific surface area is 212.12m2 / g, the pore volume is 0.7 cm3 / g, the pore diameter is 5.013 nm, and the pHpzc is 6. The initial concentration of phenol was 100 mg / L, 2 L of water samples were taken, the hypergravity factor β was 40, the liquid flow rate was 85 L / h, the gas flow rate was 60 L / h, the gas phase ozone concentration was 60 mg / L, and the catalyst dosage The pH value is 110 g / L, the pH value is 6, the wastewater circulation reaction is 30 min, and the TOC removal rate reaches 96.42%. When the pH is 2, the TOC removal rate reaches 79.73%, and when the pH is 12, the TOC removal rate reaches 60.74%. , Compared with traditional equipment, it is increased by 21%, and the utilization rate of ozone is increased by 30%.

Embodiment 2

[0034] Example 2: Using figure 1 In the process shown, CuO-Fe2O3 / γ-Al2O3 catalyst is used as filler to degrade phenol wastewater in a supergravity field. The active components Cu: Fe are 2% and 2% respectively, and the specific surface area is 172.32 m2 / g, the pore volume is 0.35 cm3 / g, the pore diameter is 10 nm, and the pHpzc is 8.5. The initial concentration of phenol is 200 mg / L, 2 L of water sample is taken, the hypergravity factor β is 30, the liquid flow rate is 65 L / h, the gas flow rate is 40 L / h, the pH value is adjusted to 8, and the catalyst dosage is 60 g / L, the gas phase ozone concentration was adjusted to 60 mg / L, and the wastewater was circulated for 30 minutes, and the TOC removal rate reached 84.21%. When the ozone concentration was 80 mg / L, the TOC removal rate was 91.42%. Compared with traditional equipment, the TOC removal rate is increased by 18%, and the ozone utilization rate is increased by 30%.

Embodiment 3

[0035] Example 3: Using figure 1 The process shown uses MnOx / SAC catalyst as filler to degrade phenol wastewater in a high-gravity field. Contains active component Mn (1%), and its specific surface area is 100.24 m2 / g, pore volume is 0.164 cm3 / g, pore diameter is 3.633nm, pHpzc is 3. The initial concentration of phenol was 300 mg / L, 2 L of water samples were taken, the gas phase ozone concentration was 80 mg / L, the liquid flow rate was 65 L / h, the gas flow rate was 60 L / h, the pH value was adjusted to 4, and the catalyst dosage was was 90 g / L, adjusted the hypergravity factor β to 60, and the wastewater was circulated for 30 minutes, the TOC removal rate reached 90.51%. When β was 0, the TOC removal rate reached 36.99%. Compared with traditional equipment, the TOC removal rate is increased by 20%, and the ozone utilization rate is increased by 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com