Paraffin hydrogenation post-treatment method

A technology of paraffin and hydrogenation reaction, which is applied in the field of post-treatment of paraffin hydrofining, which can solve the problems of increasing the difficulty of subsequent environmental protection system processing and wasting hydrogen resources, so as to save fresh water consumption, save equipment investment costs, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

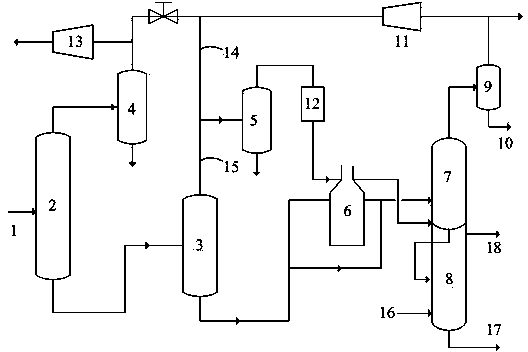

[0027] Test device: a small hydrogenation test device equipped with a hydrorefining reaction system, with a figure 1 The small aftertreatment system shown is just that the heating furnace is replaced by electric heating tubes.

[0028] Hydrofining reactor loaded with catalyst FV-10 catalyst (commercial wax hydrofinishing catalyst developed by Fushun Petrochemical Research Institute) 100 mL.

[0029] Test raw materials: melting point 59.5°C, color, Saybolt number +10, light stability No. 6, bromine taste No. 2, oil content 0.28% (mass).

[0030] The purity of hydrogen is 99.99%.

[0031] Reaction conditions: reaction temperature 260°C, reaction pressure 6.0MPa, feed rate 150mL / h, hydrogen wax volume ratio 300.

[0032] Post-processing operating conditions: the pressure of the hot high-pressure separator is 6.0 MPa and the temperature is 220°C; the pressure of the hot low-pressure separator is 0.5 MPa and the temperature is 200°C; the pressure of the first-stage stripping towe...

Embodiment 2

[0035] The test device is the same as in Example 1.

[0036] Hydrofining reactor loaded with catalyst FV-10 catalyst (commercial wax hydrofinishing catalyst developed by Fushun Petrochemical Research Institute) 100 mL.

[0037] Test raw materials: melting point 63.5°C, color, Saybolt number +14, photostability No. 9, bromine taste No. 3, oil content 0.35% (mass).

[0038] The purity of hydrogen is 99.99%.

[0039] Reaction conditions: reaction temperature 270°C, reaction pressure 6.5MPa, feed rate 100mL / h, hydrogen wax volume ratio 320.

[0040] Post-processing conditions: the pressure of the hot high-pressure separator is 6.5 MPa, and the temperature is 220°C; the pressure of the hot low-pressure separator is 0.5 MPa, and the temperature is 200°C; the pressure of the first-stage stripping tower is 0.1MPa, the stripping temperature is 220°C, the hydrogen 50L / h; the pressure of the secondary stripping tower is 0.02 MPa, the stripping temperature is 220°C, and the new hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com