Method for preparing calcium sulfoaluminate-alite-belite-iron phase system cement clinker by phase separation combination

A technology of calcium sulfoaluminate and cement clinker, which is applied in the field of cement clinker, can solve the problems of high formation temperature of tricalcium silicate, difficulty in production operation, and decomposition of tricalcium silicate, so as to avoid abnormal setting time and reduce The difficulty of preparation and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of calcium sulfoaluminate-Alite-Beilite-iron phase system cement clinker of the present invention, the burning of clinker takes the electric furnace method as an example, and concrete steps are as follows:

[0030] 1. According to the principle of preparation of mineral combinations with the same temperature range formed by calcination, the present invention divides cement clinker into C 3 S-C 2 There are two groups of S-iron phase system clinker and sulphoaluminate cement clinker (that is, calcium sulphoaluminate-dicalcium silicate-iron phase system clinker), among which sulphoaluminate cement clinker is commercially available. During preparation, first calculate C according to the mineral composition of the calcium sulfoaluminate-Alite-Beilite-iron phase system cement clinker and the mineral composition of the existing sulfoaluminate cement clinker 3 S-C 2 The percentage content of each mineral in the clinker of the S-iron phase system.

[00...

Embodiment approach

[0037] Further, the mineral composition of the sulphoaluminate cement clinker of the present invention is: calcium sulphoaluminate, belite or dicalcium silicate, iron phase, anhydrous calcium sulfate; C 3 S-C 2 The mineral composition of the clinker in the S-iron phase system is: alite, belite, iron phase, and free calcium oxide. The mineral composition content of sulfoaluminate cement clinker is (wt%): calcium sulfoaluminate 50-70%, dicalcium silicate 15-30%, iron phase 2-10%, anhydrous calcium sulfate 0-8% , Free calcium oxide 0-0.5%. In the preferred embodiment of the present invention, the mineral composition content of the sulphoaluminate cement clinker used is (wt%): 65% calcium sulphoaluminate, 23.1% belite dicalcium silicate, 6.1% iron phase, no Calcium sulfate water 5.51%, free calcium oxide 0.29%; the chemical formula of the iron phase is C 4 A x f 2-x , 0≤X<2.

[0038] In the case of sulphoaluminate cement clinker with the above mineral composition content, C ...

Embodiment 1

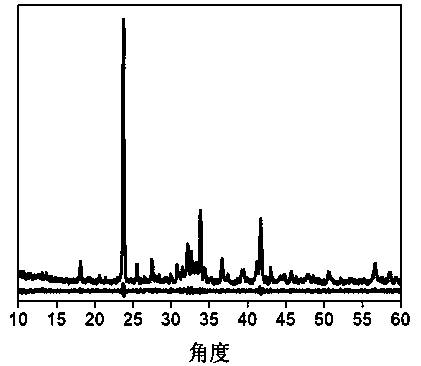

[0044] The mineral composition of sulphoaluminate cement clinker was calculated by Rietveld full spectrum fitting, and the results are shown in Table 1. figure 1 is the XRD pattern of sulphoaluminate cement clinker. C 3 S-C 2 The rate value of clinker in S-iron phase system is KH=0.86, SM=3.09, IM=0.64.

[0045]

[0046] Ingredients: The amount of raw material is calculated according to the three rate values, and the specific oxide ratio is shown in Table 2. Wet mixing is adopted, according to raw material: ball: water = 1:1:1. Put the weighed sample into a sealed mixing tank, ball mill and mix for 1-2 hours, then take it out and dry it. Mix the raw material evenly, add about 7-10wt% water, use a φ40 mm*40 mm mold, press the load 15-20 MPa, and press it into a 10-15 g green sheet.

[0047] Firing system: calcining the green sheet, raising the temperature to 800-1000°C at a rate of 5°C / min, holding it for 40 minutes, then raising the temperature at a rate of 3°C / min to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com