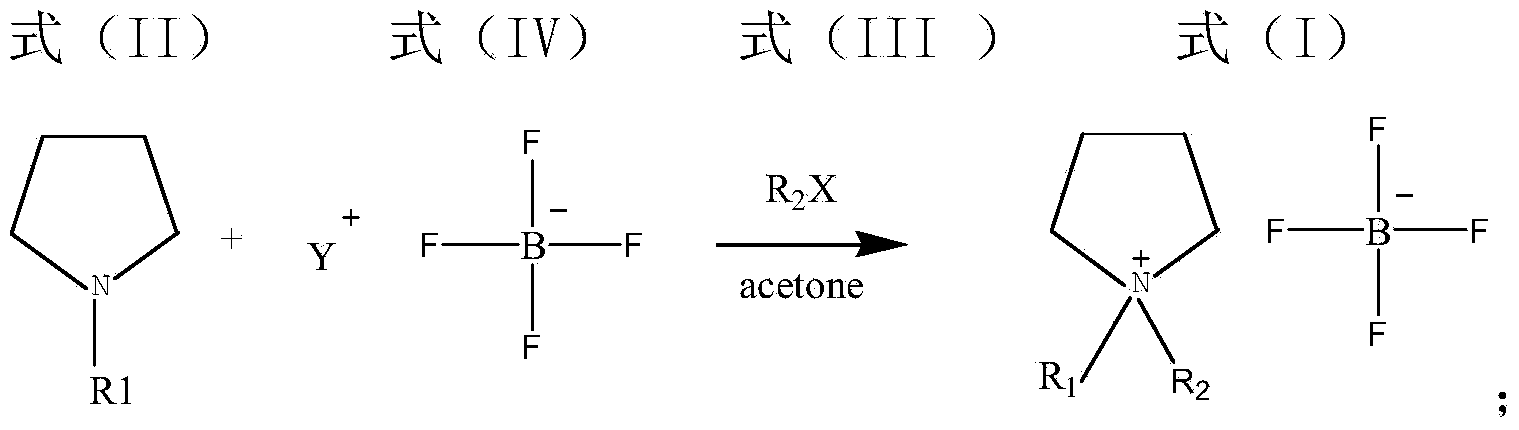

Preparation method and industrialized production method of pyrrolidinium with tetrafluoroborate anions

A technology of tetrafluoroborate and pyrrolidinium salt, which is applied in the field of preparation of pyrrolidinium salt, can solve the problem that the synthesis process and refining process are not suitable, the synthesis method and purification method are not mentioned, and the manufacturing cost is high, etc. problems, to achieve the effect of facilitating industrialized continuous mass production, low production cost, and easy product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

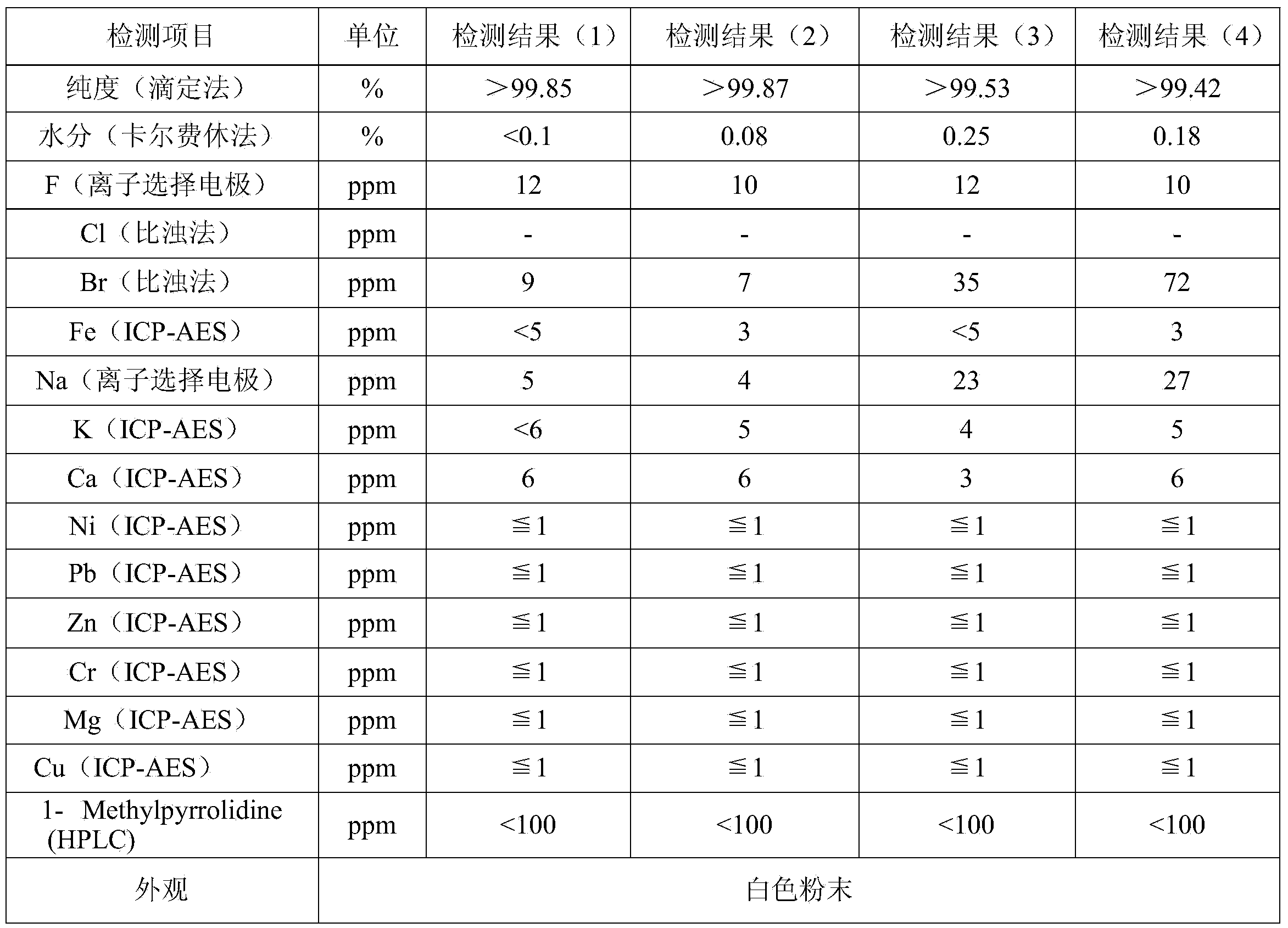

Embodiment 1

[0032] Take a 1000mL three-necked flask and add 129.43g of N-methylpyrrolidine, 183.60g of sodium fluoroborate, and 130mL of acetone into a cold water bath and stir. Set the stirring frequency to 35Hz. Add 182.19g of bromine dropwise within 5 hours at 30°C. Ethane, continue to stir for 19 hours after the dropwise addition, remove the solid by-product by centrifuge filtration, and distill the filtrate under reduced pressure to obtain a white solid (that is, the crude product of pyrrolidinium salt with tetrafluoroborate anion), add 150g of isopropanol, stir and heat up to 65°C, slowly cool down to crystallize after the white solid is completely dissolved, control the cooling rate to 10°C / h, until the crystal mixture is completely precipitated, centrifugally filter the crystal mixture, and filter the filtered crystal mixture with isopropanol Propanol was used for rinsing to obtain a rinsing liquid. The content of bromide ions in the rinsing liquid was detected by the acetone-silve...

Embodiment 2

[0034] Take a 1000mL three-neck flask and add 129.43g of N-methylpyrrolidine, 183.60g of sodium fluoroborate, and 130mL of acetone into a cold water bath and stir. Set the stirring frequency to 35Hz. Add 182.19g of bromine dropwise within 25 hours at 0°C. Ethane, continue to stir for 47 hours after the dropwise addition, remove the solid by-products by centrifuge filtration, and distill the filtrate under reduced pressure to obtain a white solid (that is, the crude product of pyrrolidinium salt with tetrafluoroborate anion), add 150g of isopropanol, stir and heat up to 40°C, slowly cool down to crystallize after the white solid is completely dissolved, control the cooling rate to 5°C / h, until the crystal mixture is completely precipitated, centrifugally filter the crystal mixture, and filter the filtered crystal mixture with isopropanol Propanol was used for rinsing to obtain a rinsing liquid. The content of bromide ions in the rinsing liquid was detected by the acetone-silver ...

Embodiment 3

[0036] Add 129.43kg of N-methylpyrrolidine, 183.60kg of sodium fluoroborate, and 130L of acetone into a 1000L glass-lined reactor and stir, set the stirring frequency to 35Hz, and drop 182.19kg of ethyl bromide within 5 hours at 55°C alkane, continue to stir for 25 hours after the dropwise addition, and remove the solid by-product by centrifugal filtration. The filtrate is injected into a vacuum distillation kettle through an infusion pump and distilled under reduced pressure until no components flow out to obtain a white solid (that is, with tetrafluoroborate anion pyrrolidinium salt crude product), then add 150kg of isopropanol to the white solid, stir and heat up to 95°C, and slowly cool down to crystallize after the white solid is completely dissolved, control the cooling rate to 15°C / h, about 55°C Observe the precipitation of crystal mixture, adjust the cooling rate to 10°C / h, continue to cool down until the crystal mixture is completely precipitated, centrifuge, filter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com