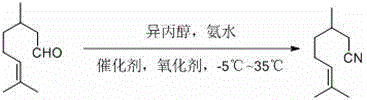

Production technology for preparing citronellyl nitrile from citronellal

A production process and citronellal technology are applied in the field of production technology for preparing citronellal from citronellal, which can solve the problems of large energy loss, environmental pollution by waste acid water, strong corrosiveness, high price and the like, and reduce labor intensity. , The effect of improving economy and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a 5-liter reaction kettle, add 785 g of isopropanol and 230 g of citronellal to mix, use nitrogen to remove the air in the kettle three times, control the reaction temperature at 15°C~25°C, quickly add 18 g of cobalt chloride and dropwise 364 g 25% ammonia water. Continue to control the temperature of the reaction solution at 15-25°C, add 340 g of 50% hydrogen peroxide, and track the reaction of citronellal with chromatography after the dropwise addition until the content of citronellal is less than 1.0%. After the reaction was completed, acetic acid was added to neutralize the reaction solution (PH = 7-8), the solvent was recovered, and 226 g of citronellolonitrile was obtained after purification, with a content of 97.6% and a yield of 87.2%.

Embodiment 2

[0022] In a 5-liter reaction kettle, add 785 g of isopropanol and 230 g of citronellal to mix, use nitrogen to remove the air in the kettle three times, control the temperature of the reaction solution at 15~25°C, quickly add 10 g of cuprous chloride and drop 425 g 25% ammonia water. Control the temperature of the reaction solution at 15-25°C, add 192 g of 50% hydrogen peroxide, and react until the citronellal content is less than 1.0% after the dropwise addition. After the reaction was completed, acetic acid was added to neutralize the reaction solution (PH = 7-8), the solvent was recovered, and 219 g of citronellyl nitrile product was obtained after purification, with a content of 98.1% and a yield of 85.0%.

Embodiment 3

[0024] In a 5 liter reactor, mix 785 g of isopropanol and 230 g of citronellal. Use nitrogen to remove the air in the kettle three times, control the temperature of the reaction solution at 3~15°C, quickly add 15 g of copper chloride and 387 g of 25% ammonia water dropwise. Control the temperature of the reaction solution at 3-15°C, add 192 g of 50% hydrogen peroxide dropwise, and react until the citronellal content is less than 1.0%. After the reaction was completed, acetic acid was added to neutralize the reaction solution (PH=7-8), the solvent was recovered, and 218 g of citronellonitrile product was obtained after purification, with a content of 97.8% and a yield of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com