Wastewater treatment device and method of sequencing batch A/O (Anaerobic/Oxic) linked system for realizing partial nitrification of wastewater

A technology of short-range nitrification and linkage system, which is applied in the field of wastewater treatment devices of sequencing batch A/O linkage system, can solve the problems of complex operation procedures and many control parameters, and achieve the effects of precise control, simple process operation flow and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

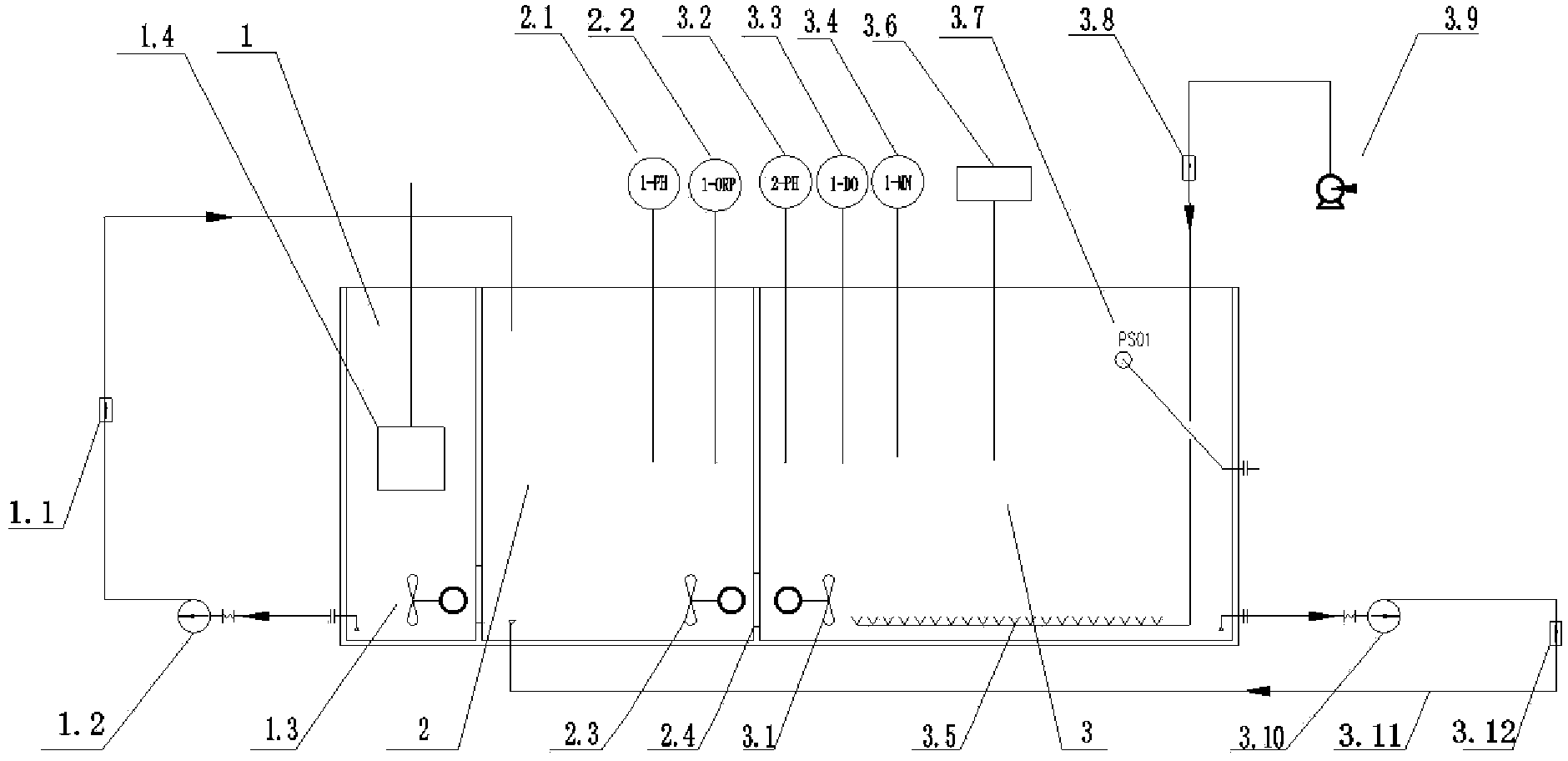

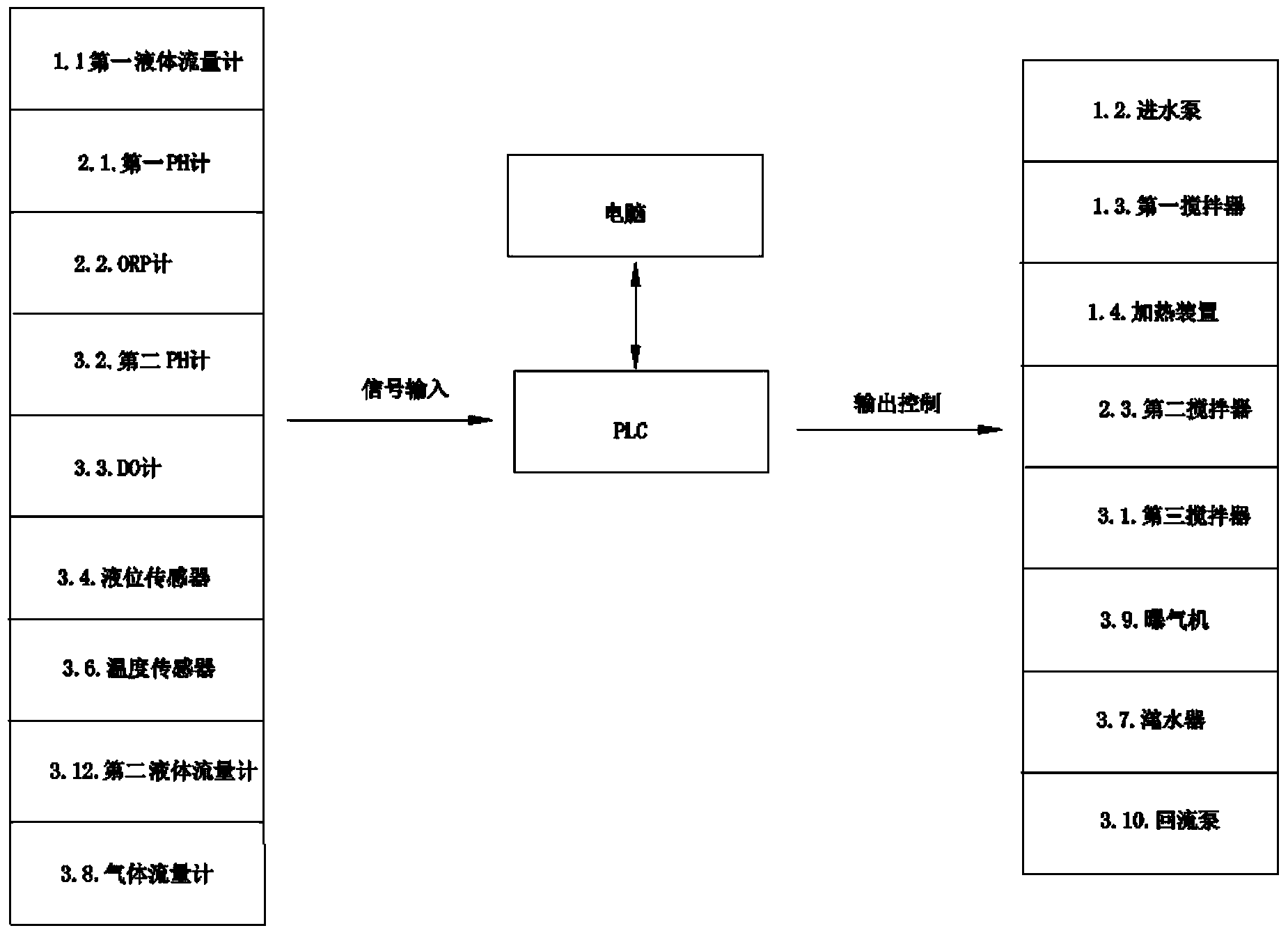

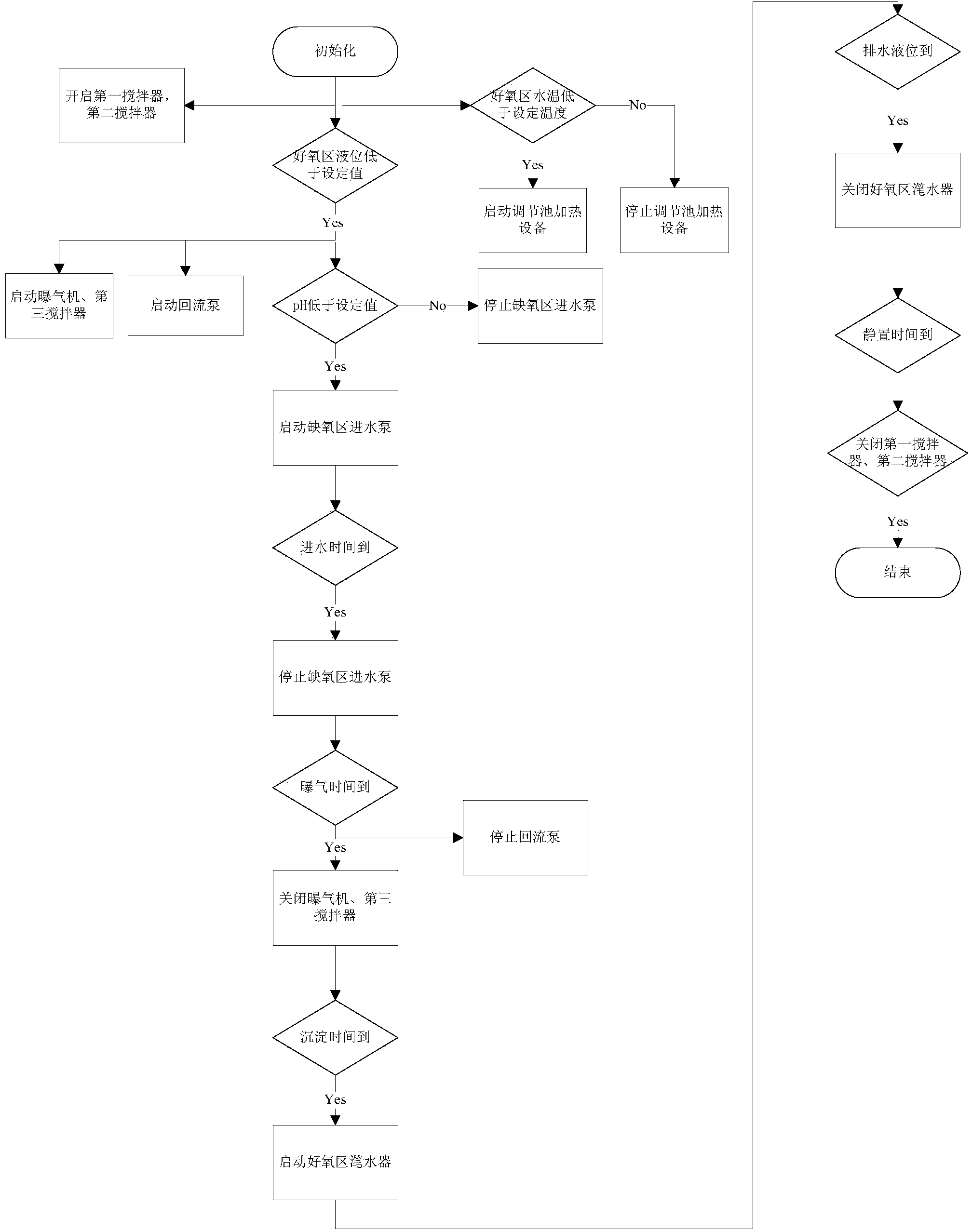

[0058] Such as figure 1 As shown, a sequence batch type A / O linkage system wastewater treatment device for short-range nitrification of wastewater is provided with a regulating pool 1 and SBR reaction pools 2 and 3, and the SBR reaction pools 2 and 3 include the SBR reaction pool anoxic Zone 2 and SBR reaction pool aerobic zone 3;

[0059] The regulating tank 1 communicates with the anoxic zone 2 of the SBR reaction tank through the water inlet pump 1.2 and the first liquid flow meter 1.1 in turn;

[0060] The anoxic zone 2 of the SBR reaction tank communicates with the aerobic zone 3 of the SBR reaction tank through the overflow tank 2.4;

[0061] An aeration pipe 3.5 is provided at the bottom of the aerobic zone 3 of the SBR reaction tank, and the aeration pipe 3.5 is connected to the aerator 3.9 through a gas flow meter 3.8;

[0062] A decanter 3.7 is provided inside the aerobic zone 3 of the SBR reaction pool;

[0063] The bottom of the aerobic zone 3 of the SBR reacti...

Embodiment 2

[0089]Adopt the sequence batch type A / O linkage system wastewater treatment device and treatment method for realizing short-range nitrification of wastewater according to the present invention to treat wastewater, wherein the size of the regulating pool is B×H×L=470×500×440cm, and the total volume is 103,400 cm L. The size of the anoxic zone of the SBR reaction pool is 470×500×440cm, with an effective volume of 100,000L; the size of the aerobic zone is 470×500×1540cm, with an effective volume of 350,000L.

[0090] Take the landfill leachate from Xiaping Solid Waste Landfill in Shenzhen City, its pH is 8.01-8.65, NH 4 + -N concentration up to 1500~3000mg / L, BOD 5 / TN is less than 3 to 5, which is a typical waste water with high ammonia nitrogen concentration and low carbon nitrogen ratio.

[0091] (1) Use the nitrification sludge from Xiaping Leachate Treatment Plant of Shenzhen City as inoculation sludge and inject it into the aerobic zone and anoxic zone of the SBR reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com