Patents

Literature

98 results about "Skin stretch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

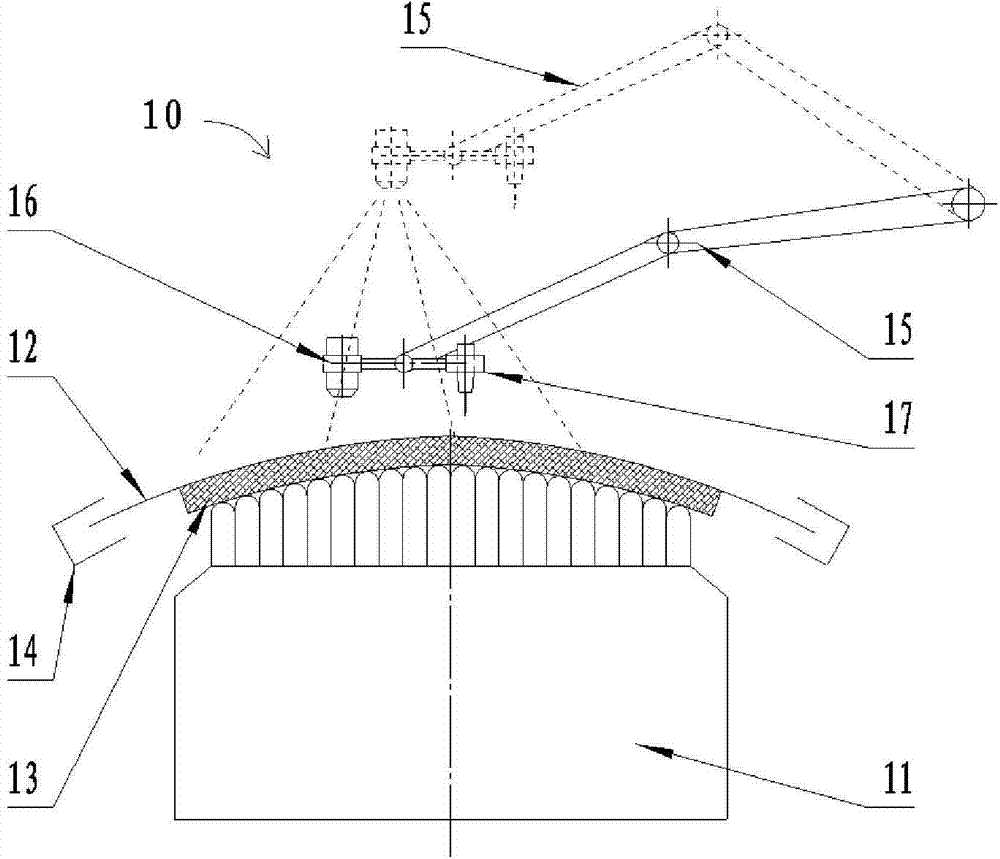

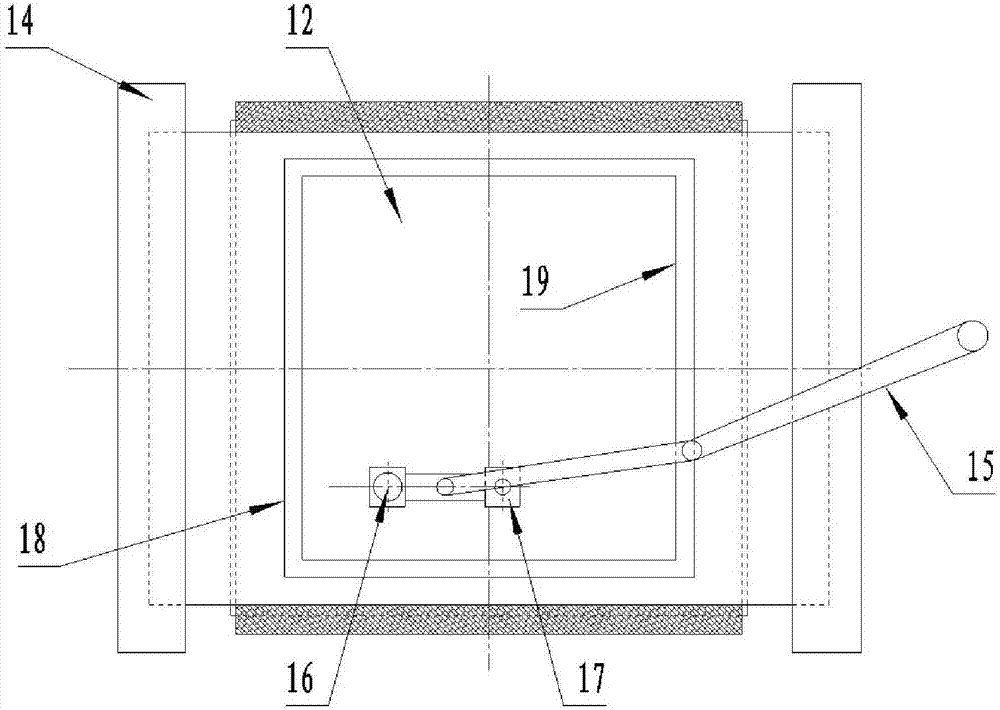

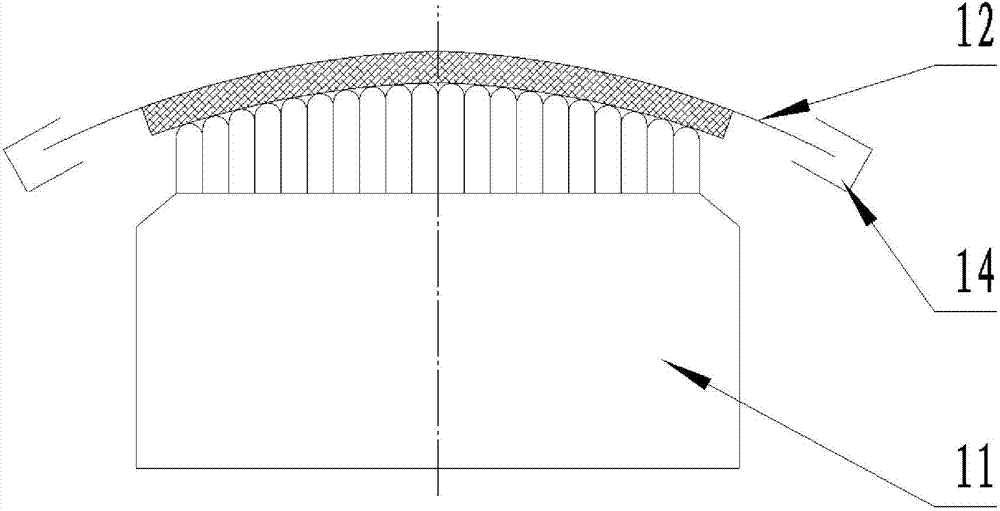

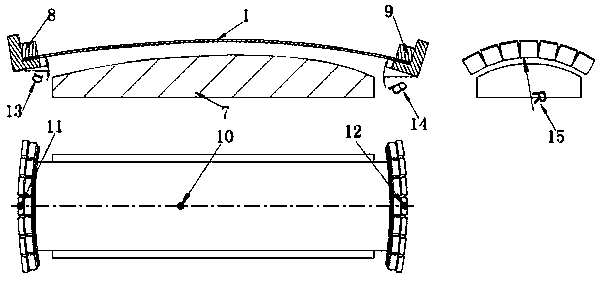

Method for skin stretch-forming and locating with flexible multipoint mould

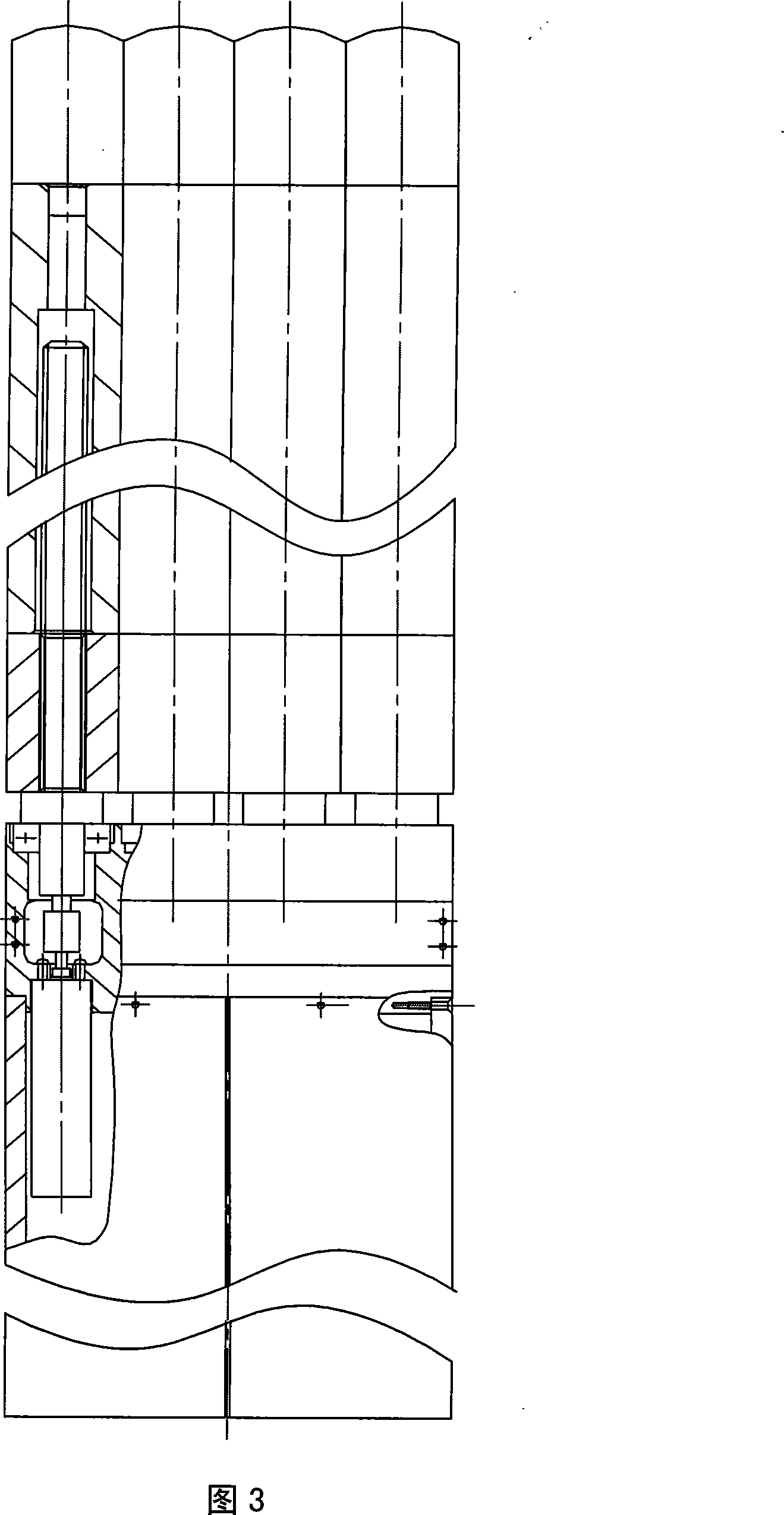

The invention provides a method for skin stretch-forming and locating with a flexible multipoint mould. The method includes the following steps of step1, a skin stretch-forming device (10) of the flexible multipoint mould is used for skin stretch-forming; step2, after the stretch-forming is finished, a multipoint mould (11) of the skin stretch-forming device (10) of the flexible multipoint mould is regulated to a theoretical number model face of a skin (12) in shape, and the skin (12) is arranged on the multipoint mould (11) and fixed; step3, geometrical information of the skin (12) is measured; step4, the accurate position of the skin (12) is calculated, and the border characteristics of the skin (12) are determined; step5, marking out or locating is carried out on the surface of the skin (12). According to the method for skin stretch-forming and locating with the flexible multipoint mould, flexible locating can be achieved, for any sectional face characteristics, no special locating overturn plate is needed, and efficiency and locating accuracy can be obviously improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

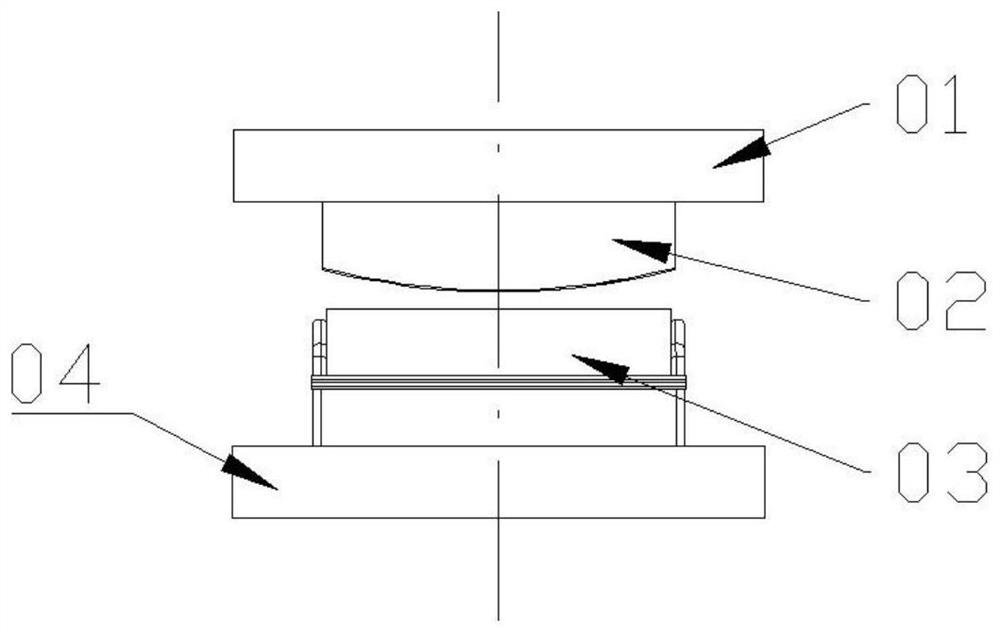

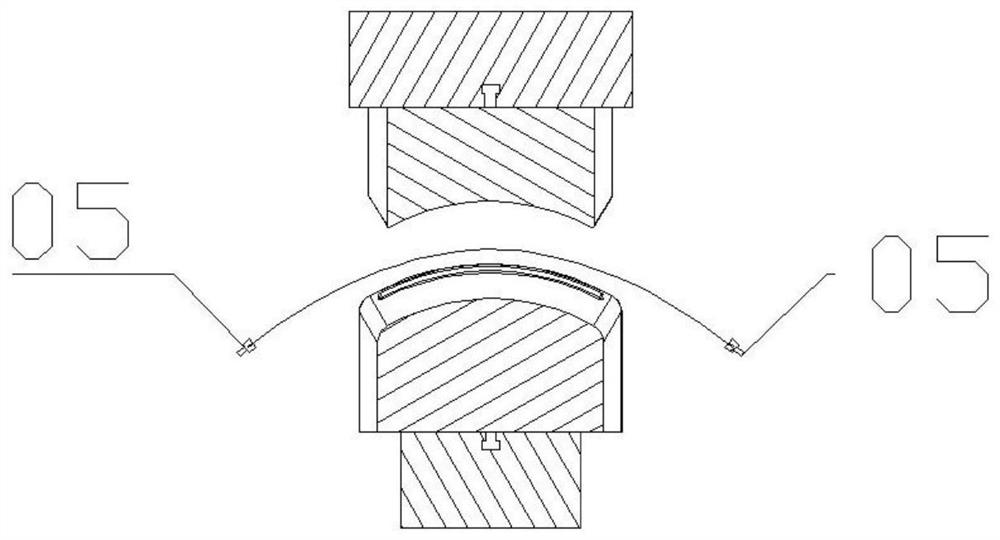

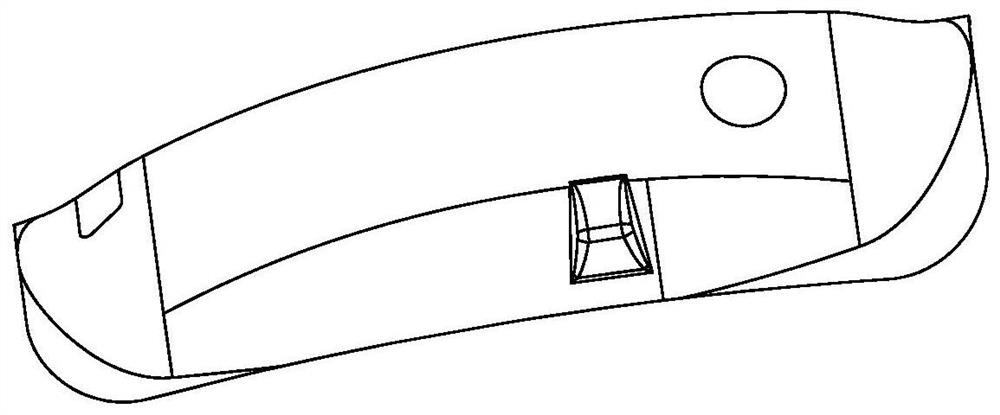

Tool for forming convex-concave multi-curvature type airplane skin product and composite forming technology

ActiveCN106270155ASolve the positioning problemImprove surface qualityShaping toolsEngineeringUltimate tensile strength

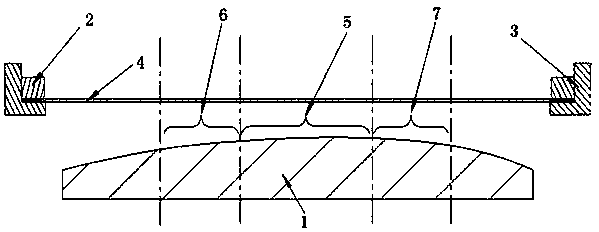

The invention relates to a tool for forming a convex-concave multi-curvature type airplane skin product and a composite forming technology. The tool comprises an upper die plate, a male die, a female die and a sealing ring. An inverted-herringbone-shaped die cavity is formed in the female die and connected with the upper die plate. The male die comprises a press plate and a vertical rib, wherein a profile which coincides with the ridge portion of the product is manufactured on the head of the vertical rib. The male die is arranged in the die cavity of the female die and fixedly connected with the upper die plate, and the sealing ring is arranged on the portion of contact between the press plate of the male die and the female die. The forming technology comprises the steps that skin stretching forming is conducted by a skin stretching facility on a plate material, and hydraulic forming is conducted on the product through a hydraulic bulging machine. The tool for forming the convex-concave multi-curvature type airplane skin product and the composite forming technology have the advantages that the forming accuracy of the product can be improved, the integrity of skin parts is guaranteed, the division number is reduced, the integral strength and the integral rigidity of the product are enhanced, the technology of the convex-concave multi-curvature type airplane skin product is simplified, the manufacturing difficulty is reduced, the production efficiency is effectively improved, the production cost is substantially reduced, and the tool and the composite forming technology can be widely applied to the industrial fields such as the aerospace field and the automobile field.

Owner:天津天锻航空科技有限公司

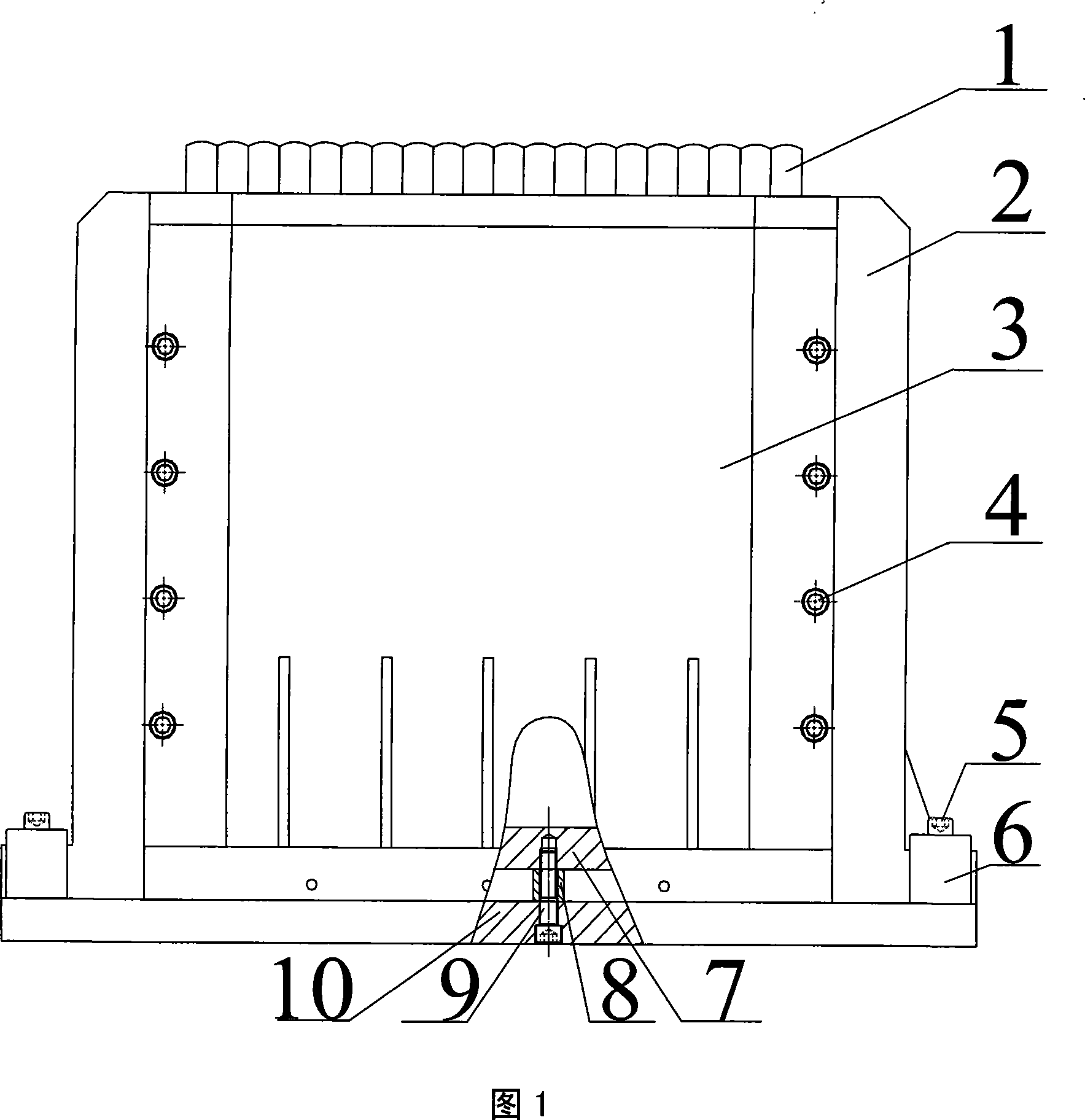

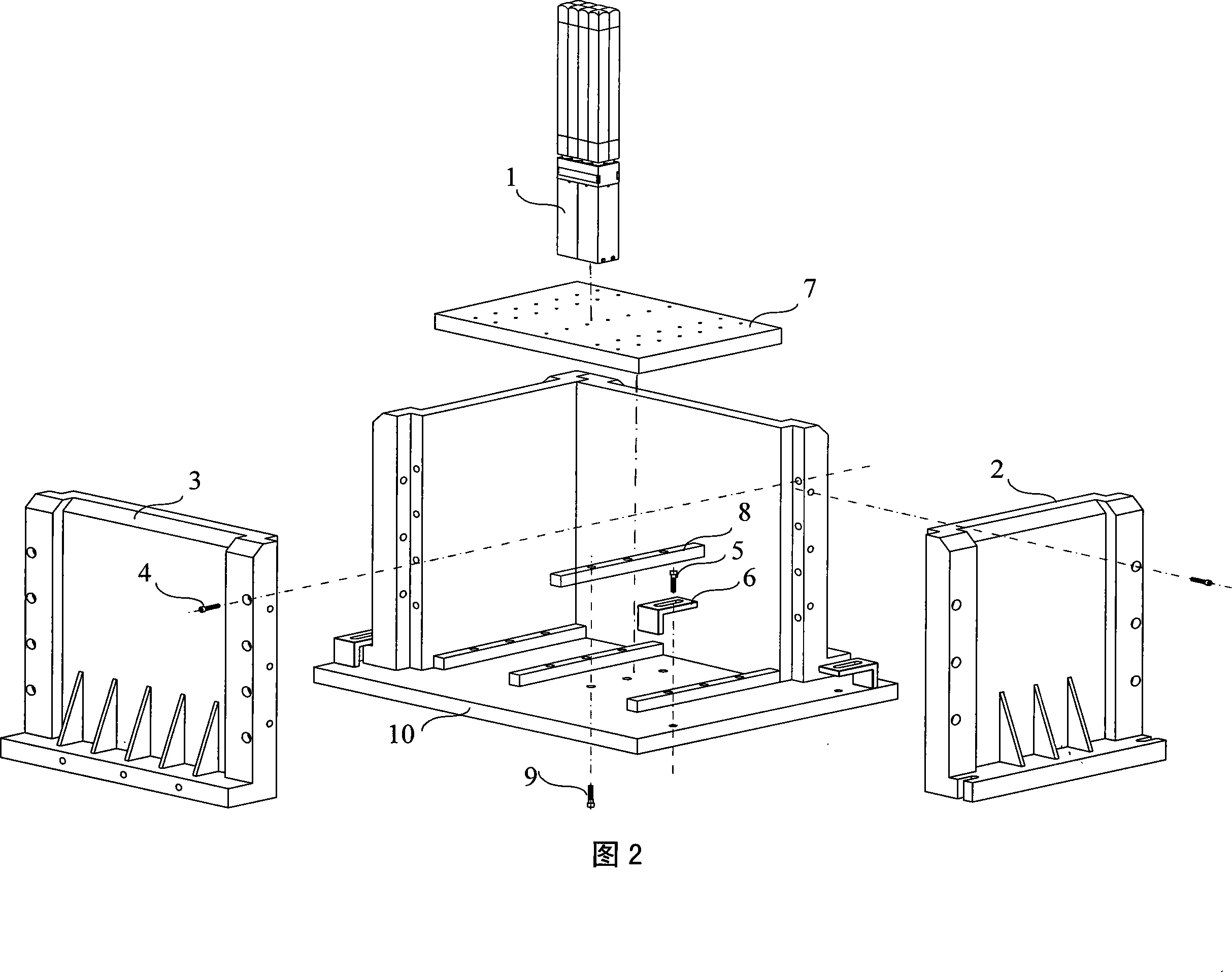

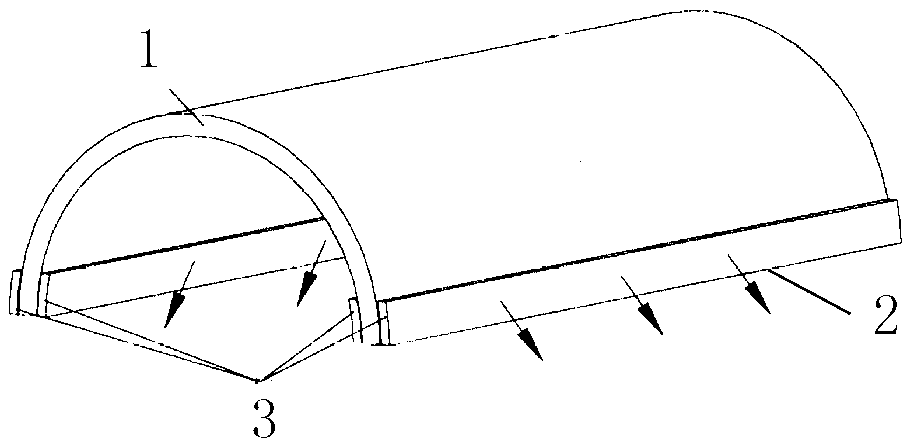

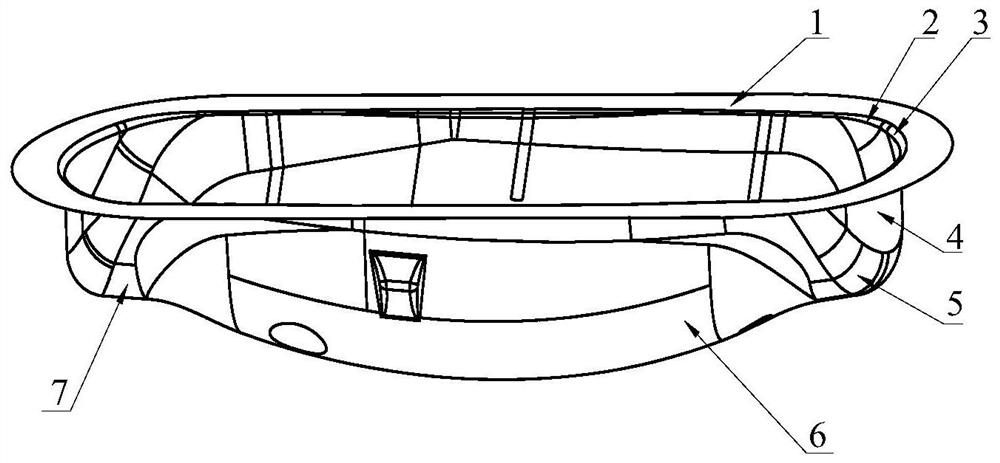

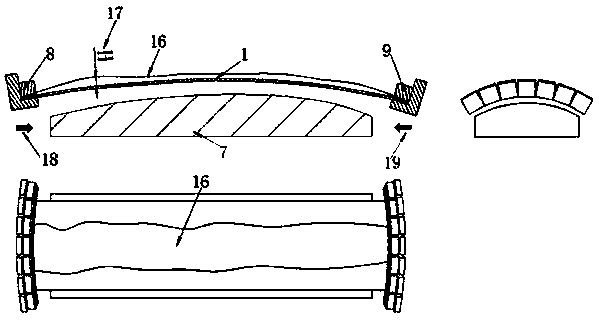

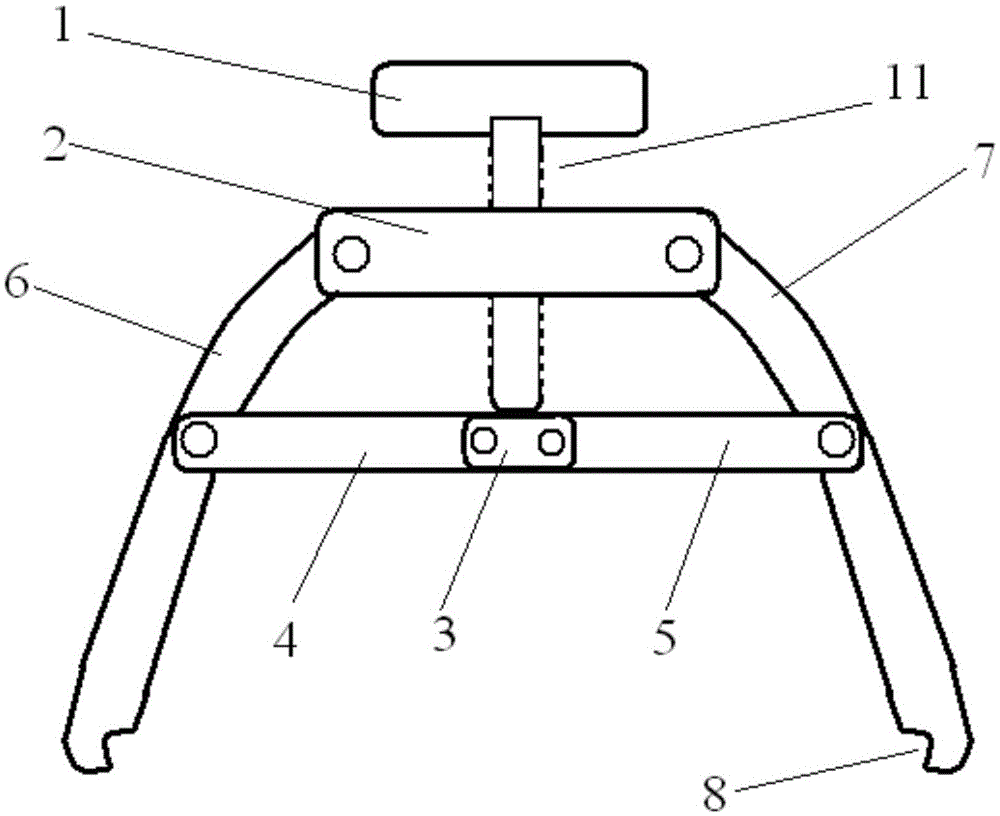

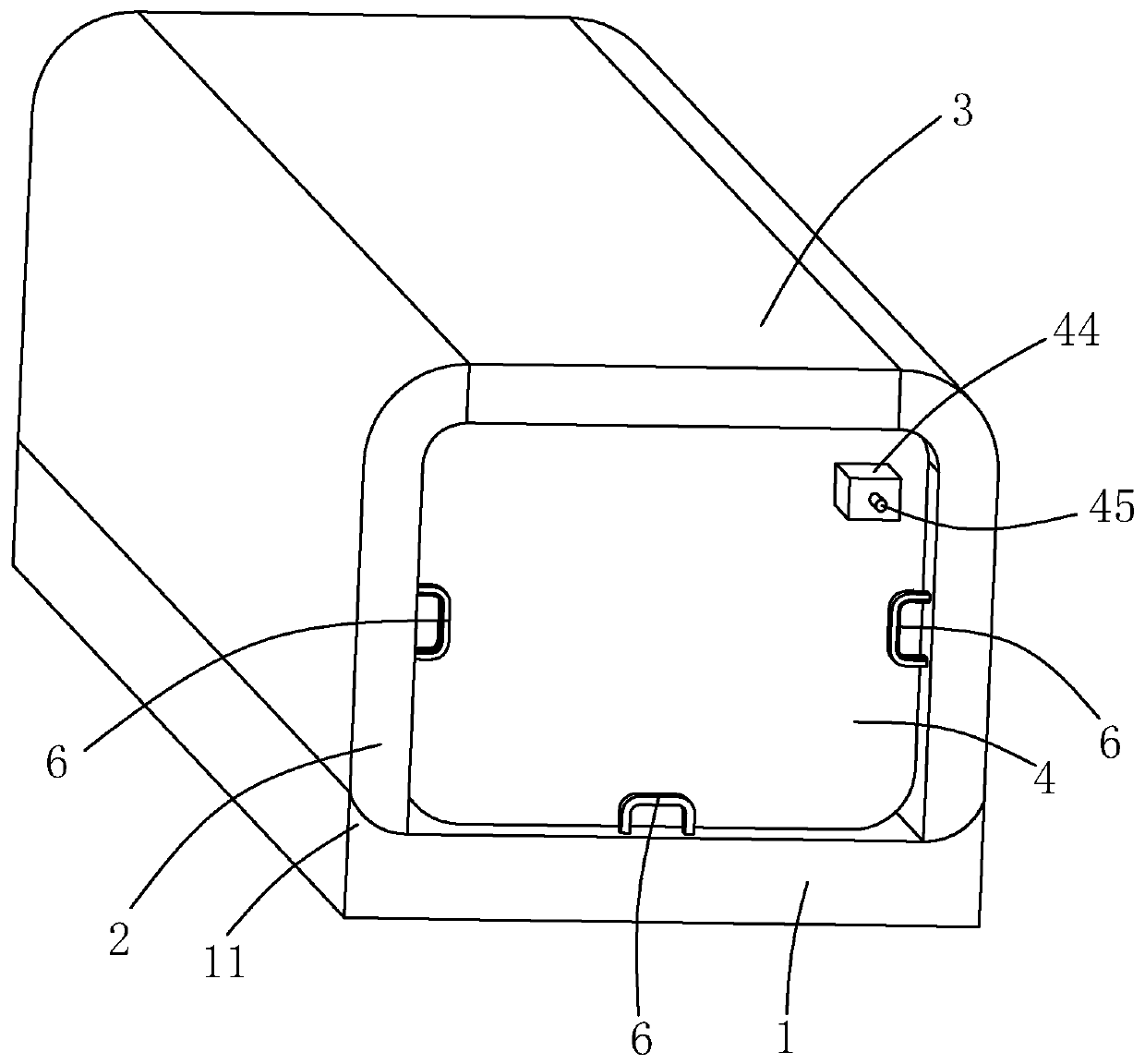

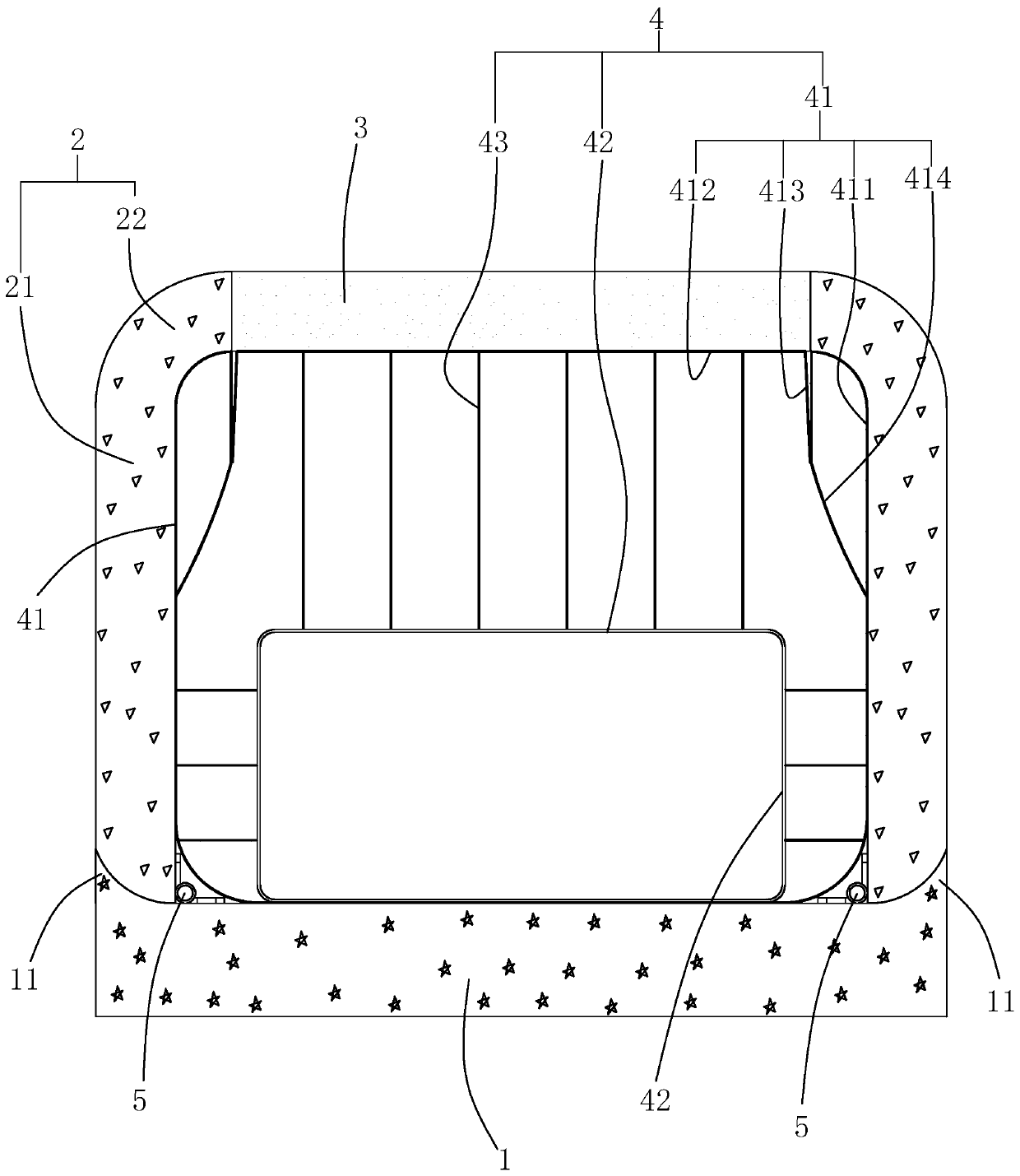

Combined reconfiguration flexible covering stretch forming mold

The invention relates to a combined, reconfigurable and flexible skin stretching and forming mold which comprises a shape adjusting unit, a bottom supporting and a positioning unit, a border tightening unit and an edge tightening unit, wherein, the bottom supporting and positioning unit is composed of a positioning board which is contacted with the bottom of the shape adjusting unit, a gasket and a supporting board; a through hole of the positioning board matched with the shape adjusting unit is arranged on the positioning board; a stepped shaft hole is positioned on the supporting board and the gasket is in the shape of a long rectangular strip on which a through hole is arranged and matched with the stepped shaft hole on the supporting board; the border fastening unit is composed of a large side plate, a small side plate and a fastening screw; positioning joint faces between the adjacent large side plate and the small side plate are staggered and connected with each other by an assembly method of over-positioning; the edge fastening unit is composed of an edge block and an edge screw and tightly fastens the border fastening unit and the bottom supporting and positioning unit by screws through the edge block and the edge screw. The invention can complete stretching formation of skins of different types with good surface quality of a skin part.

Owner:BEIHANG UNIV

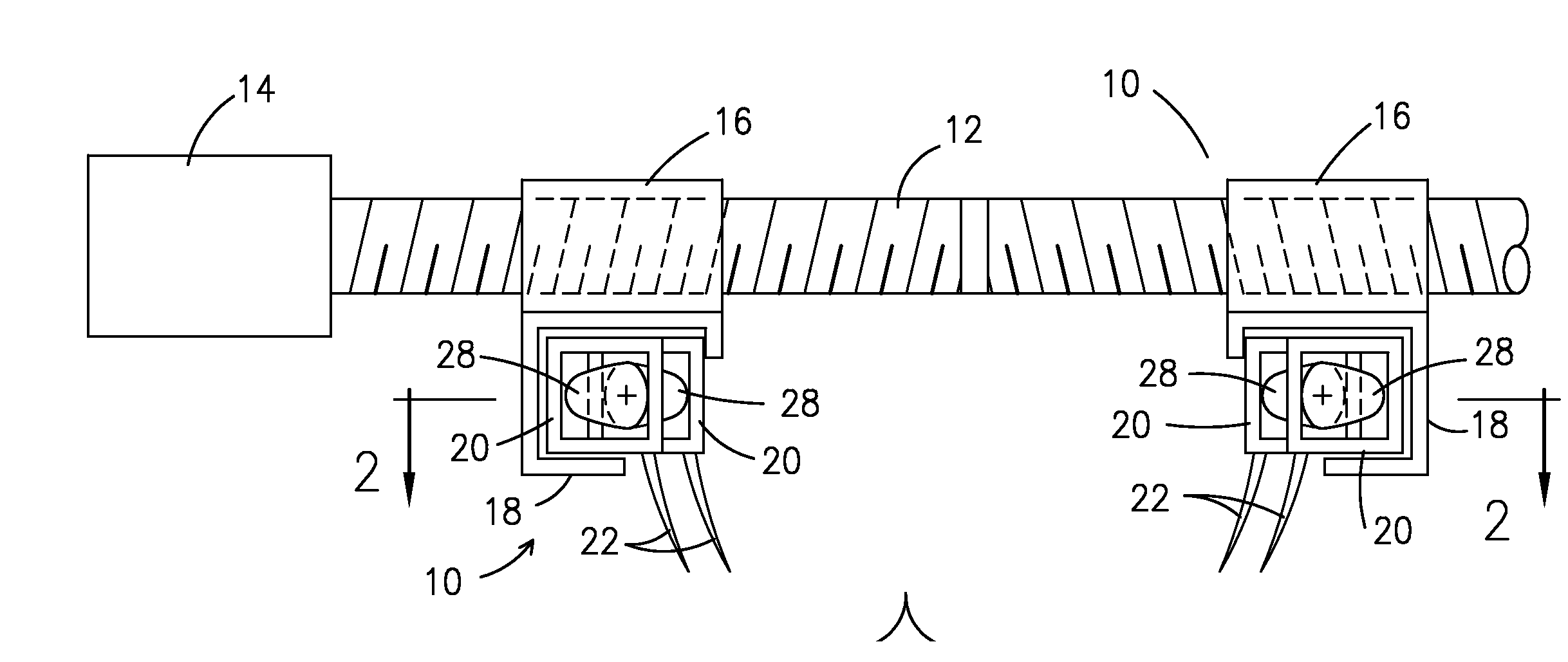

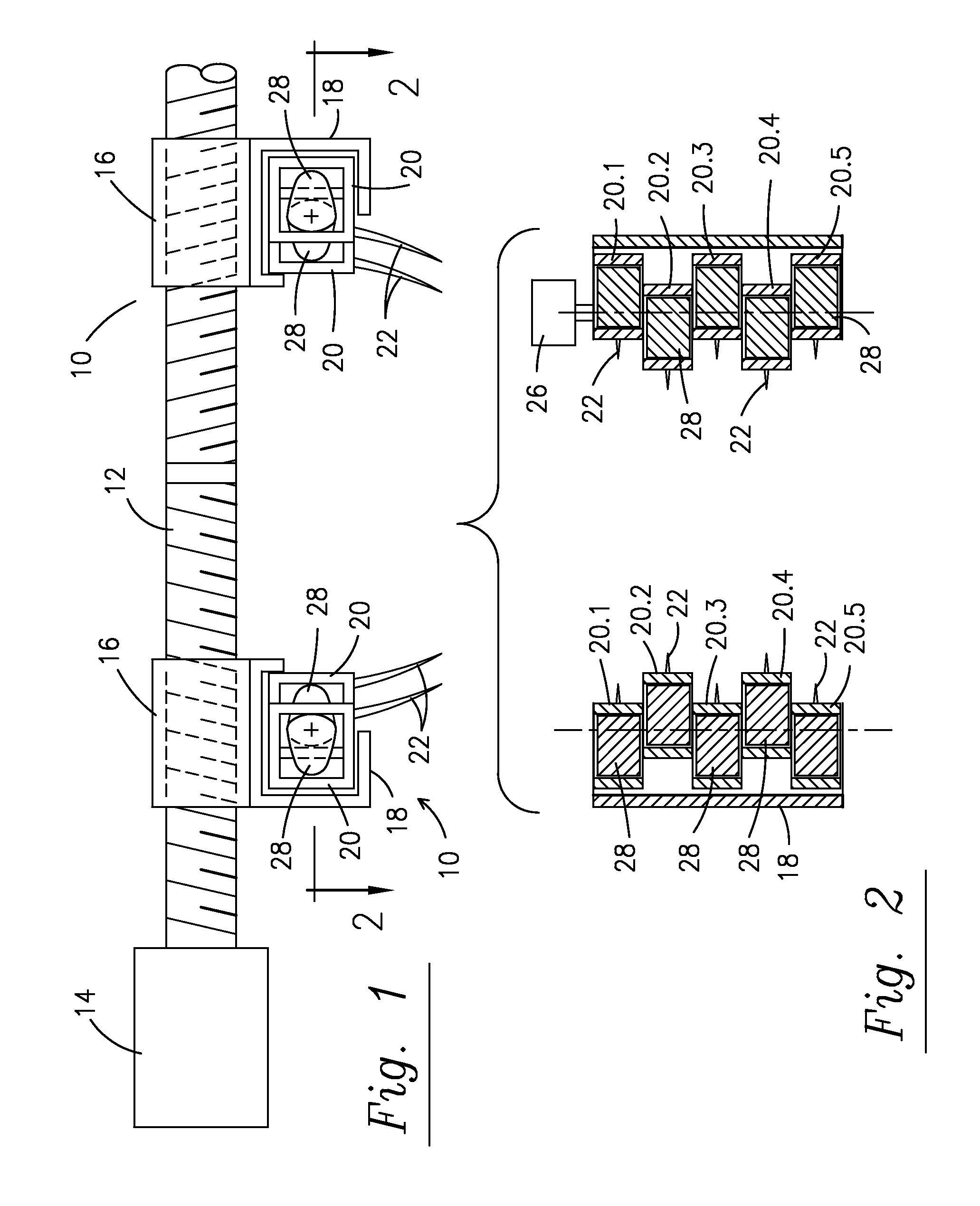

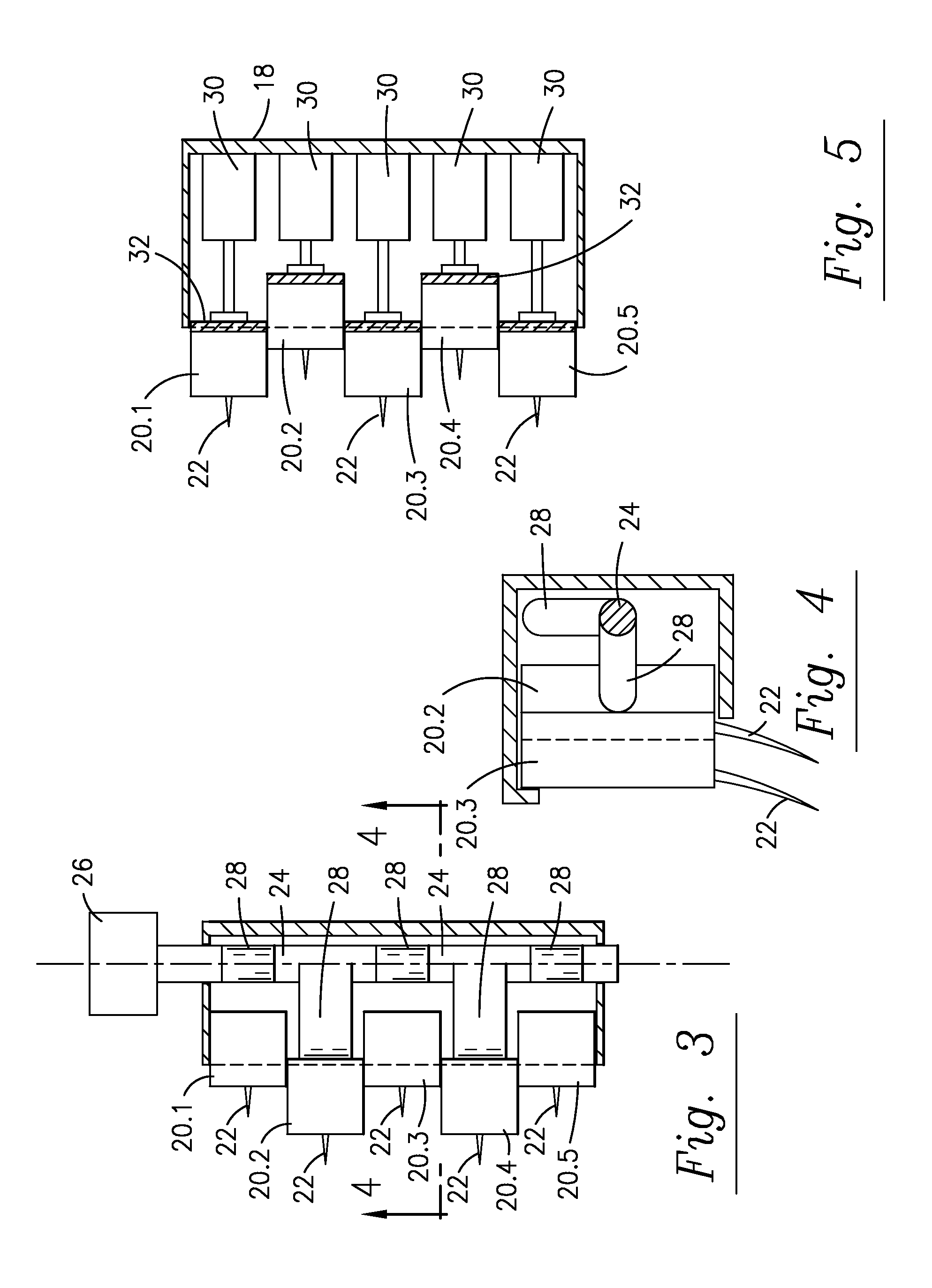

Process and instrument for stretching tissue of skin

An instrument for stretching tissue is provided. The instrument can include opposing hook jaws 10 movably coupled to a rod 12 and movable toward each other, and each hook jaw 10 can have a hook receptacle 18. A hook module 20, having at least one hook 22, can be seated in the hook receptacle 18. An adjustment cam 28 can be connected to each hook module 20 and an adjustment drive 26 can be coupled to the adjustment cams 28 where the adjustment drive 26 moves the adjustment cams 28 to cause a skin stretching force at one or more hook modules 20 and to cause a skin reperfusion force at one or more hook modules 20.

Owner:FLEISCHMANN WILHELM

Forming method capable of guaranteeing quality of chemically-milled thick skin workpieces

The invention provides a forming method capable of guaranteeing quality of chemically-milled thick skin workpieces. The method specifically includes the steps: selecting a non-prestretched plate for producing a skin blank, and reserving jaw clamping allowances in two jaw directions of the skin blank; preparing four process aluminum rods with sizes equal to the reserved jaw clamping allowances in the jaw directions; adhesively bonding the process aluminum rods with the skin blank; adopting a skin stretching machine for prestretching the skin blank to enable the skin blank to form a pre-stretched plate with low internal stress; in a part forming process, adopting an aluminum rod bonding method for guaranteeing clamping force of a jaw of the skin stretching machine on the blank, performing chemical milling after forming, and cutting off the process aluminum rods and the jaw clamping allowances reserved in the jaw directions to form a skin workpiece; and finishing, painting and inspecting. The blank is pre-stretched to enable the internal stress of a skin material to be decreased, so that deformation of chemical milling is reduced, plasticity is excellent during forming, and forming quality of the chemically-milled thick skin workpieces is guaranteed.

Owner:SHENYANG AIRCRAFT CORP

Healthcare capsule for improving skin moisture

The invention relates to a healthcare capsule for improving skin moisture, which is capable of effectively solving the dry skin problem, improving skin moisture, being taken conveniently, and increasing skin stretching property and skin elasticity. The technical scheme is as follows: the healthcare capsule is prepared from the following raw materials: 200-230g of collagen powder, 35-50g of grape seed extract, 15-20g of vitamin E powder, 6-10 g of Aloe vera gel, and 60-80g of microcrystalline cellulose, wherein all the raw materials are respectively crushed and sieved through an 80-mesh sieve; then, after the grape seed extract powder, the vitamin E powder and the Aloe vera gel powder are mixed, the collagen powder and the microcrystalline cellulose powder are mixed uniformly to be encapsulated; each capsule is 0.35g; if necessary, fine powder adhered on the surface of the capsule is eliminated; and, the capsule is loaded into a high-density medicinal polyethylene bottle after screening to remove unqualified capsules. The healthcare capsule disclosed by the invention has a scientific and rational prescription and abundant raw materials; the process is easy to operate and produce; the healthcare capsule is convenient to take and has a good effect; the skin moisture can be effectively improved; and the skin health is protected.

Owner:三门峡山水方正生物科技有限公司

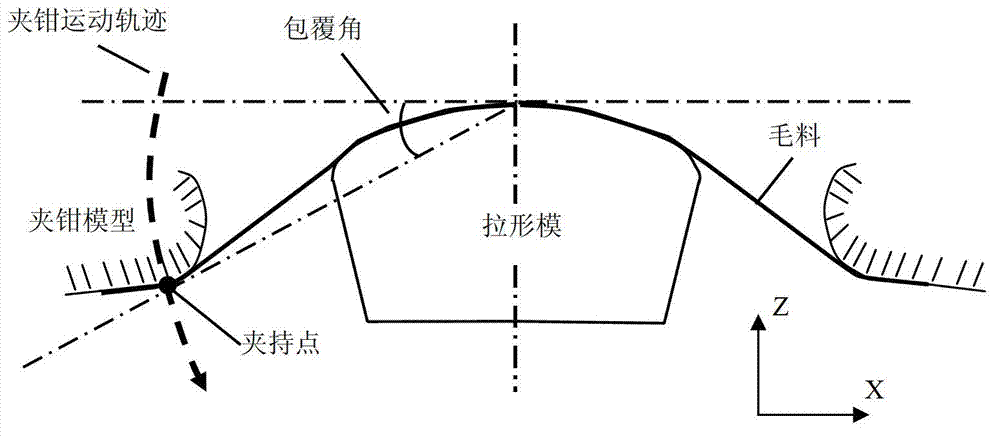

Mould positioning method based on feature distance

InactiveCN103302162ARapid positioningLittle influence on forming accuracyMetal-working feeding devicesPositioning devicesControl engineeringMotion parameter

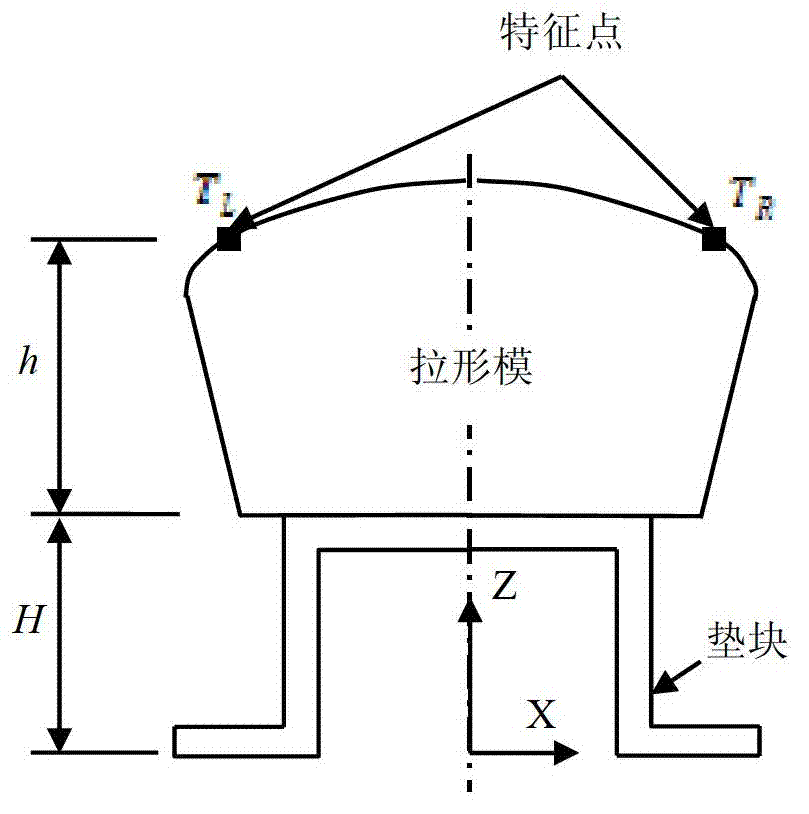

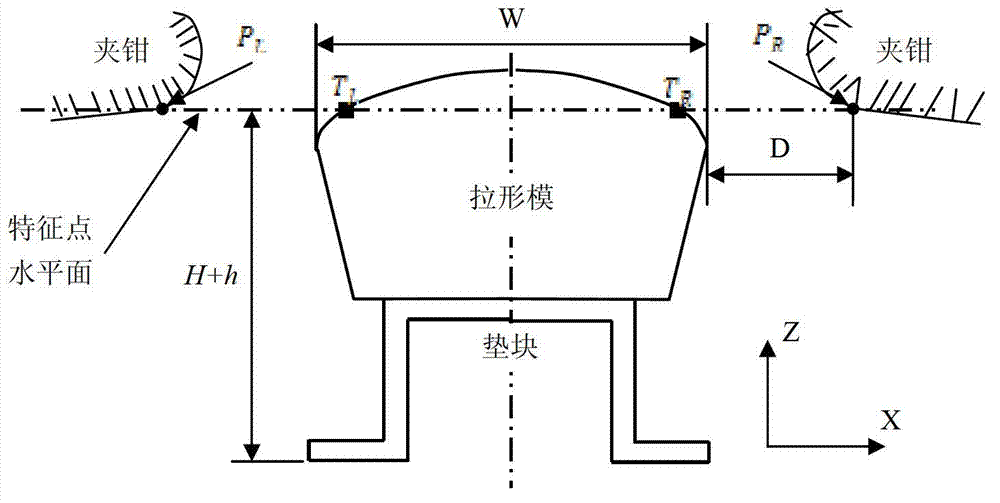

The invention discloses a mould positioning method based on a feature distance. The method comprises the following five steps: 1, initially putting a mould, namely (1) putting a cushion block and (2) putting the mould; 2, moving equipment, namely (1) determining a coordinate, (2) reversing the equipment and (3) driving the equipment; 3, measuring and calculating, namely (1) measuring the distance and (2) geometrically calculating; 4, carrying out positioning calculation on the mould; and 5, correcting a digital control code for stretch forming. According to the method, the equipment is driven to move by motion parameters of a clamp position reversing stretch-forming machine according to equipment features of a ACB FET series digital control horizontal drawing machine, the coordinate and the space position of a mould feature point are calculated by the distance between a clamp feature point and the mould feature point, and the digital control code for the stretch forming is redesigned according to a mould position, thereby achieving accurate skin stretch forming; and due to a mould putting process in the method, the mould putting error redundancy can be increased, the mould putting time can be shortened, the use of a positioning tool can be reduced, and the production efficiency of aircraft skin stretch forming can be improved.

Owner:BEIHANG UNIV

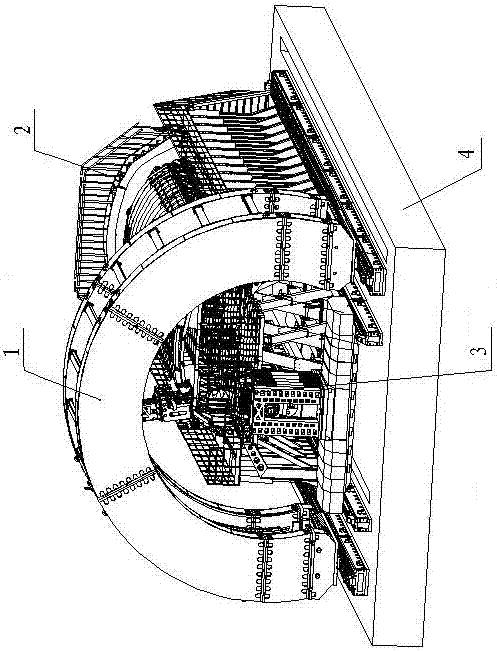

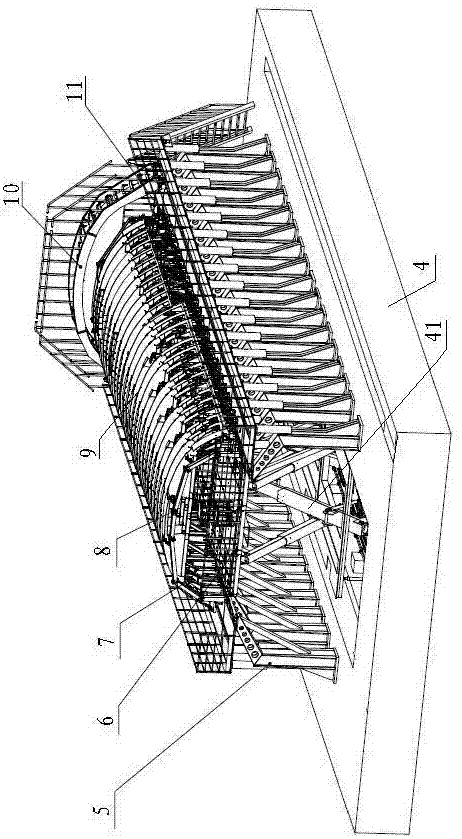

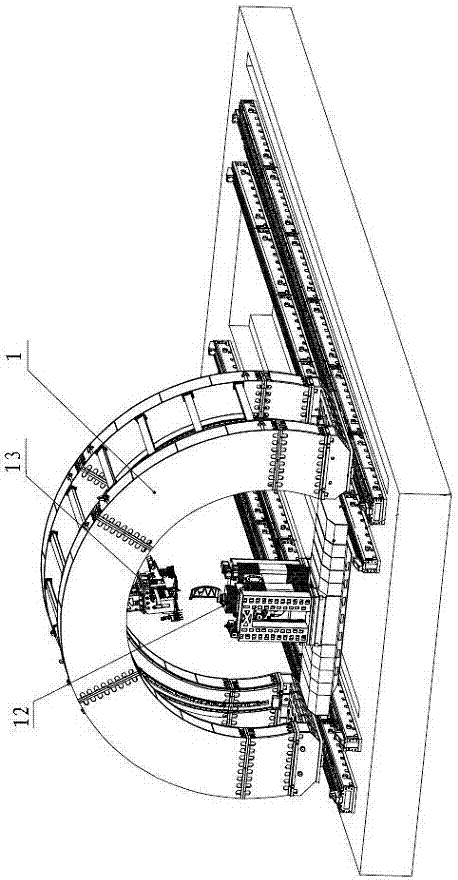

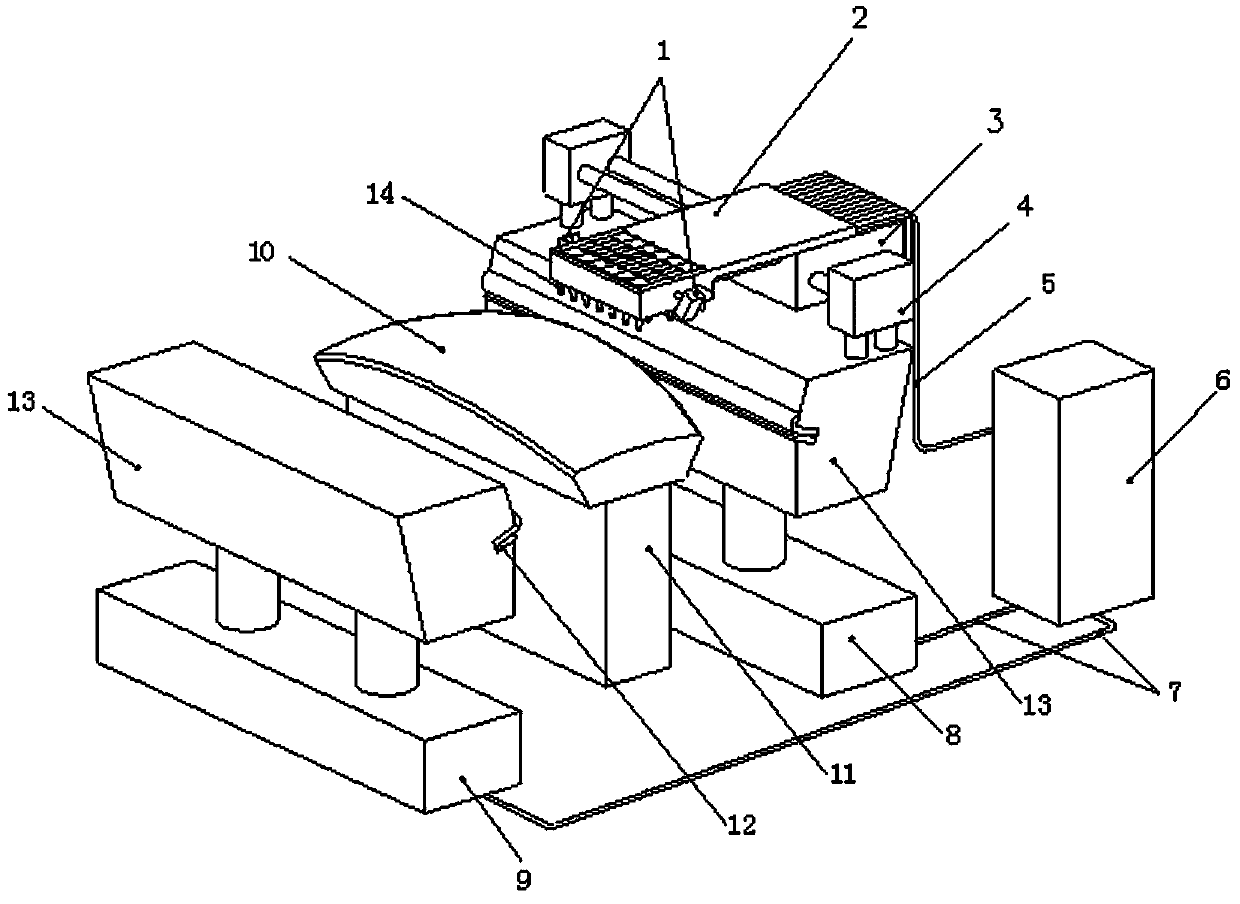

Aircraft wall panel digitalization processing and assembling system

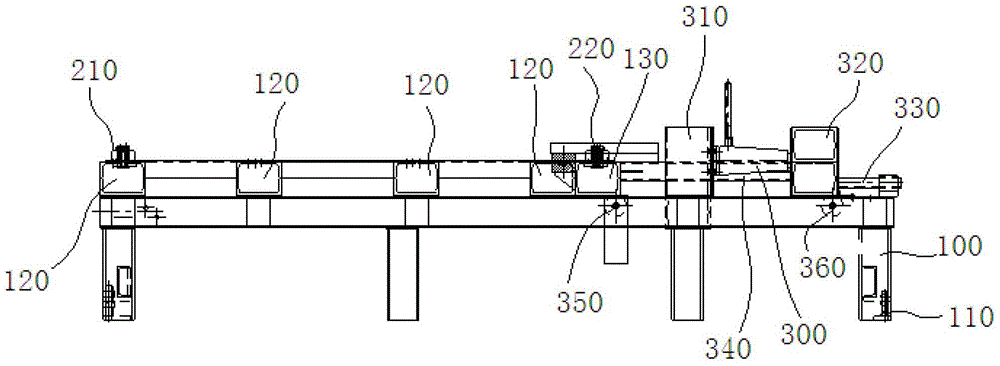

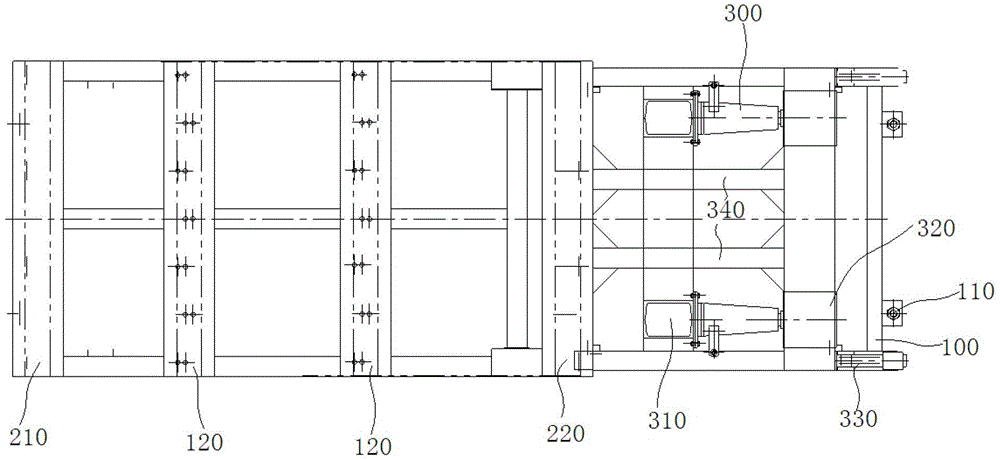

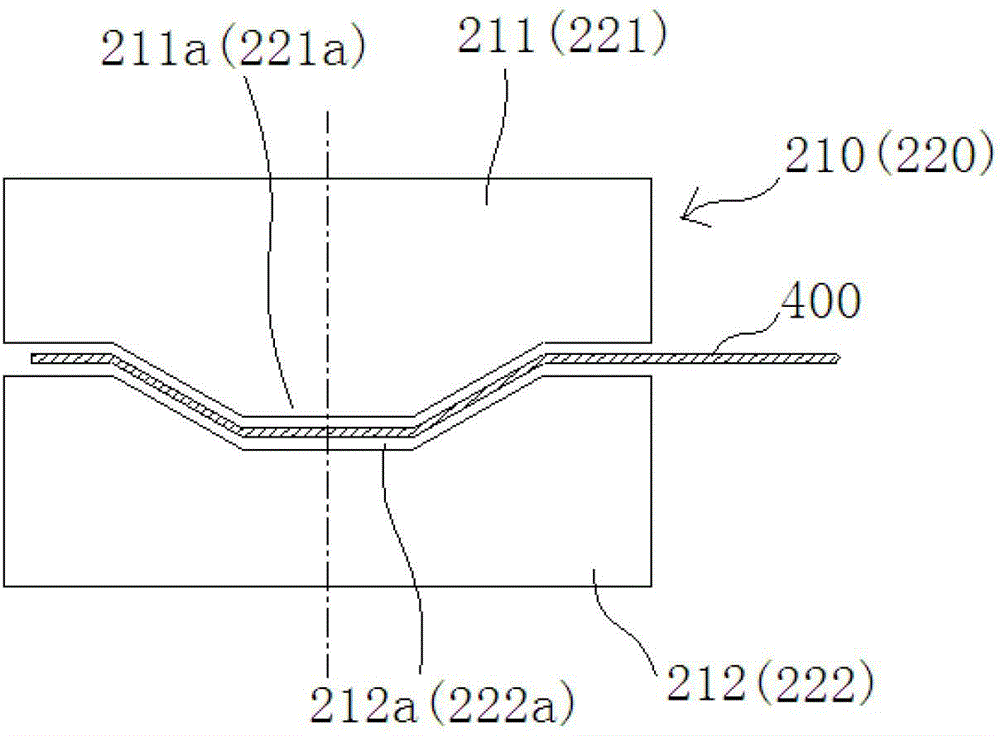

PendingCN107499530AHigh functional integrationConducive to manual operationAircraft assemblyWeight reductionEngineeringAirplane

The invention discloses an aircraft wall panel digitalization processing and assembling system. The system comprises a skin side execution system, a stringer side execution system and a skin locating tool, wherein the skin locating tool comprises a tool platform, a lifting platform, a frame locating component, a skin locating component, a multifunctional working ladder, a skin tension component and a frame; the skin side execution system comprises a tool body, an arc gantry and a skin side tail end executor; the stringer side execution system comprises a base, a stringer side tail end executor, stand pillars, slide bases and slide rails. According to the aircraft wall panel digitalization processing and assembling system, drilling and rivet pressing are integrated, and compared with a D-type gantry, the arc gantry is simpler in algorithm. Regarding the maximal processing range, a 180-degree super wall panel can be processed; the function integration level is high, and the aircraft wall panel digitalization processing and assembling system integrates the functions of drilling, dimpling, bore diameter detection, gumming, pegging, rivet pressing, normal searching, cutter changing, off-line programming, simulation and the like. An automatic locating tool is assembled, the liftable platform is assembled at the bottom of the tool, manual operation is facilitated, that the equipment and the like pass through the bottom of the tool is not influenced either, and the processing efficiency is greatly improved.

Owner:大连四达高技术发展有限公司

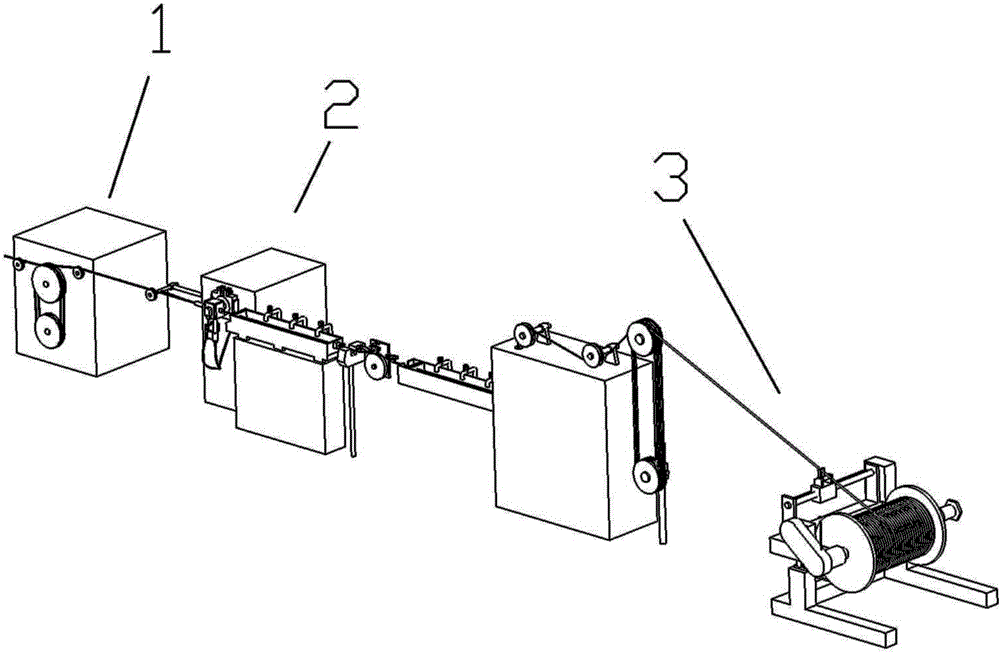

Insulation extruding and winding production line for twisted electric wires

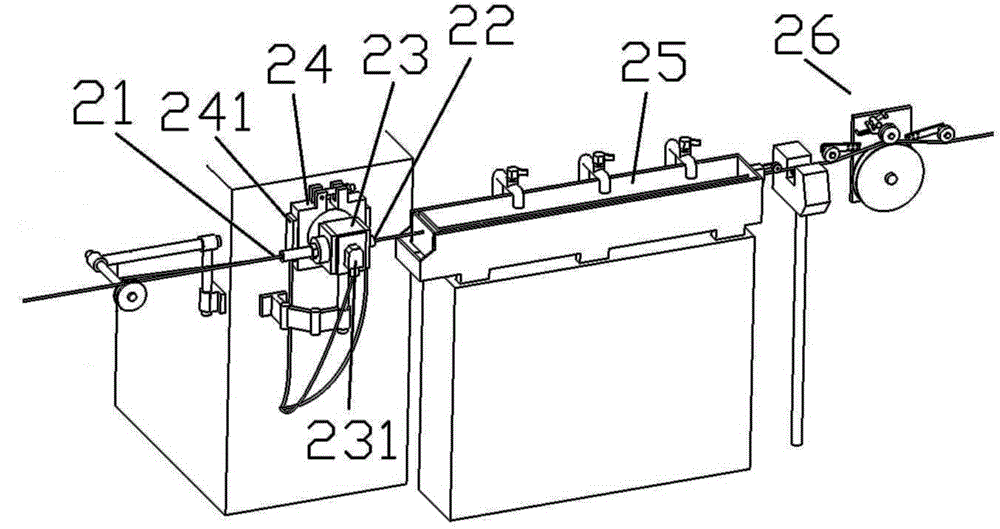

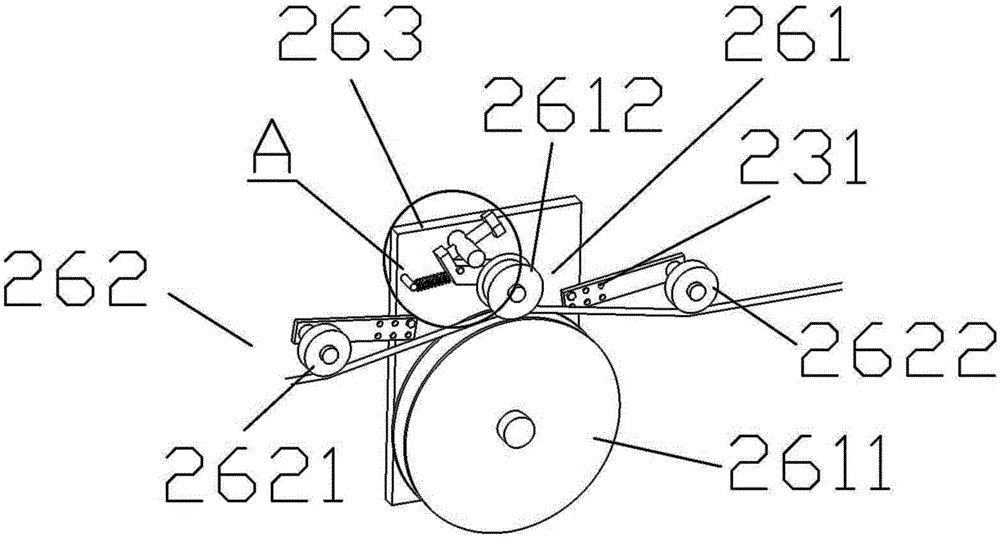

ActiveCN104952556AImprove insulation performanceEasy to collectInsulating conductors/cablesProduction lineEngineering

The invention relates to an insulation extruding and winding production line for twisted electric wires, and belongs to the technical field of wire cable processing. The insulation extruding and winding production line sequentially comprises a twisted electric wire stretching device, electric wire insulation skin processing equipment and an electric wire stretching and winding device, and is characterized in that the electric wire insulation skin processing equipment comprises a twisted wire inlet, an insulated wire outlet, a forming section for communicating the twisted wire inlet and the insulated wire outlet, an extruding section connected with the forming section, a shaping section for cooling shaping of insulated wires output from the insulated wire outlet, as well as an electric wire insulation skin stretching device, wherein a first heating part is arranged on the shaping section; two second heating parts are arranged on the two sides of the extruding section. According to the insulation extruding and winding production line for twisted electric wires, provided by the invention, the electric wires produced by adopting the production line are good in insulating effect, long in service lives and easy to store and transport.

Owner:ANJI TENGFEI ELECTRONICS

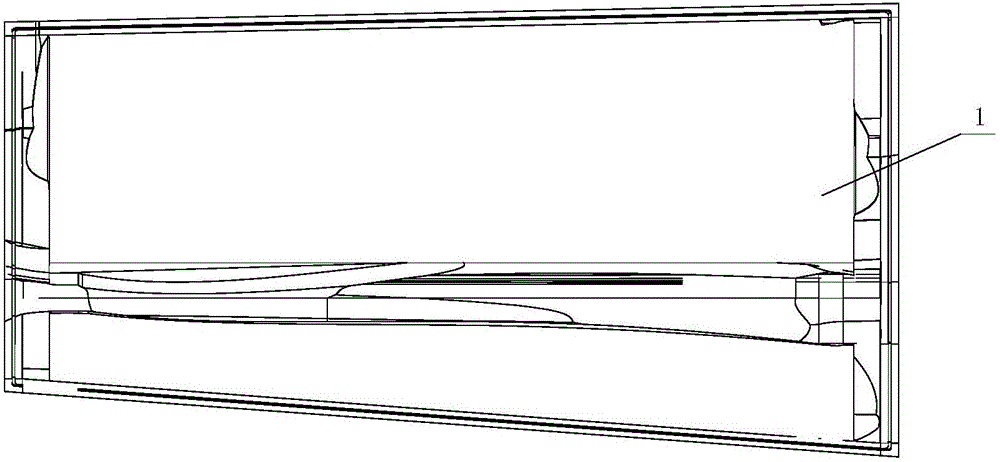

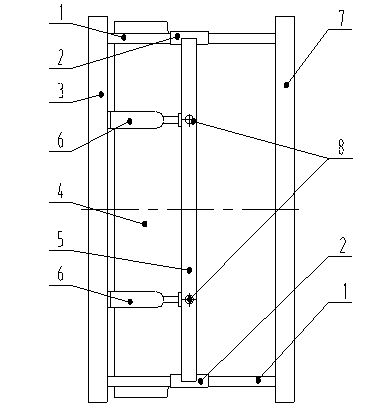

Novel skin stretching device

The invention relates to the field of coaches, in particular to a novel skin stretching device. The novel skin stretching device at least comprises a rectangular frame structure, wherein the rectangular frame structure is formed by two positioning shafts and two frame beams. The novel skin stretching device is characterized in that two sliding sleeves are respectively and fixedly connected with both ends of a sliding rod, and the two sliding sleeves are respectively in sliding connection with the two positioning shafts of the rectangular frame; linkage cylinders are fixedly arranged on one frame beam, and the power output ends of the linkage cylinders are fixedly connected with the sliding rod; and the sliding rod is connected with a connecting plate by bolts. Because the expansion amount of the linkage cylinders are the same, the problem of skin deformation caused by uneven stress of skin in a stretching direction is solved; the connecting plate is connected with the sliding rod together by the bolts, and both surfaces of the connecting plate can be reused for many times, so that the use rate of equipment is increased; and additionally, after the connecting plate is used to a certain degree, the connecting plate can be easily replaced.

Owner:SHAANXI EUROSTAR AUTOMOBILE

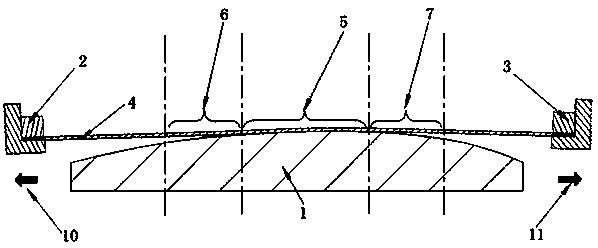

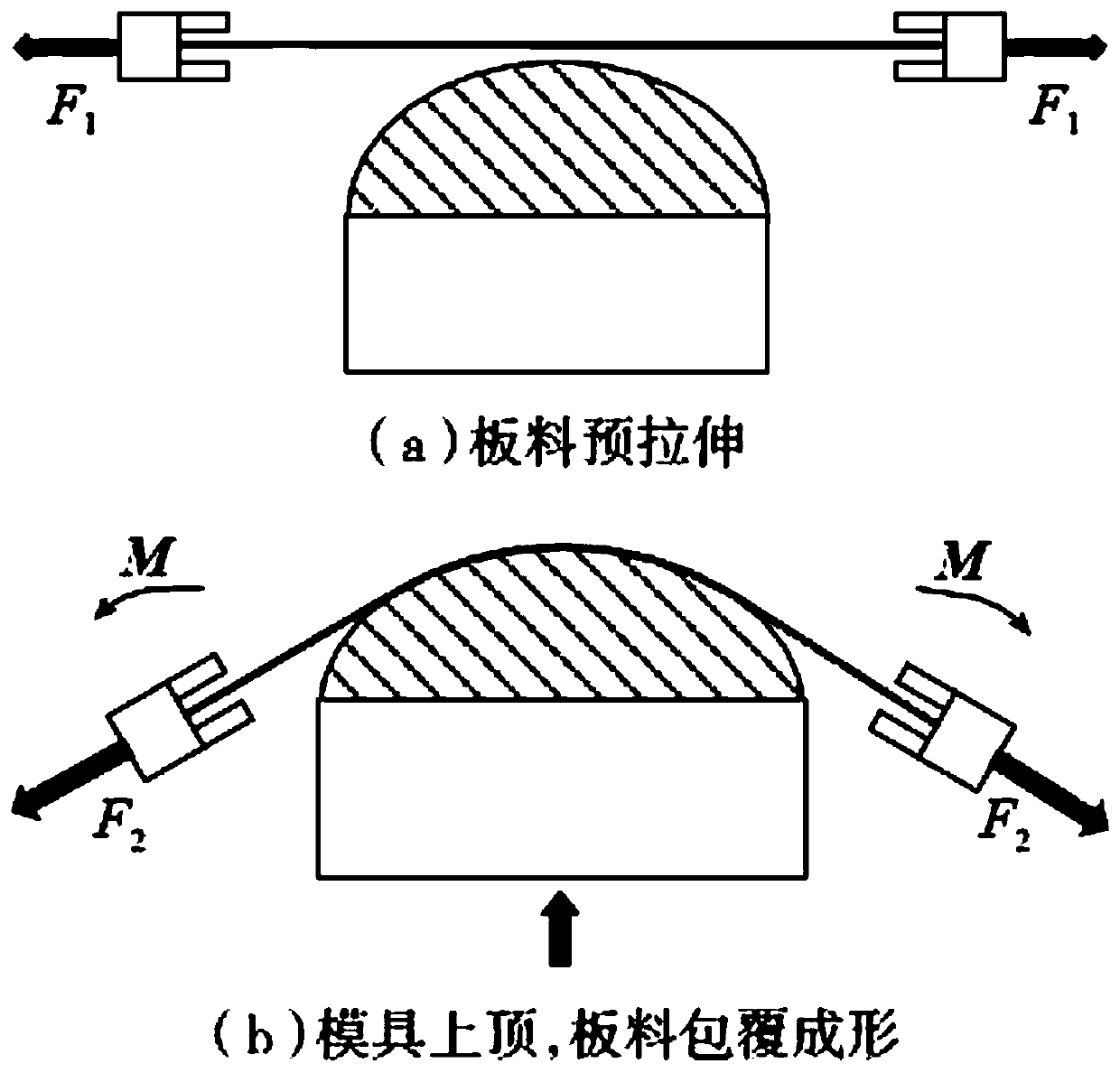

Forming method of saddle-shaped skin part

InactiveCN111745027AGuaranteed stabilityGuaranteed reliabilityAircraft componentsShaping toolsSkin stretchingPull force

The invention belongs to the field of forming and manufacturing of aerospace sheet metal parts, and relates to a ribbed tool and forming technology for forming of a double-curvature aircraft skin part. The tool is characterized by comprising a stretch-forming equipment upper workbench, an upper stretch-forming die, a plate material, a lower workbench, a clamping jaw, a stretch-forming die drawbeadand a lower stretch-forming die. The upper stretch-forming die is connected with the stretch-forming equipment upper workbench, the lower stretch-forming die is connected with the lower workbench, and convex rigs are additionally arranged on the stretch-forming dies. During skin stretch-forming, with the combination of pressure adjustment of the upper workbench and control over a friction lubricating mode, a blank maintains uniform bidirectional pulling force by changing the stress mode of the part through the drawbead, the uniformity and controllability of flowing of the part in the formingprocess are ensured, and rapid integral forming of the part with reverse double curvatures is realized.

Owner:SHAANXI AIRCRAFT CORPORATION

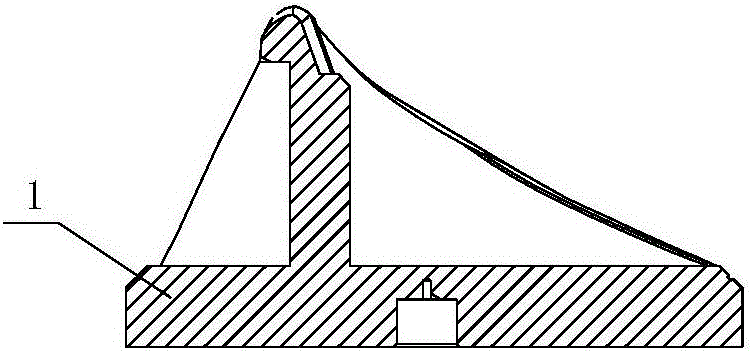

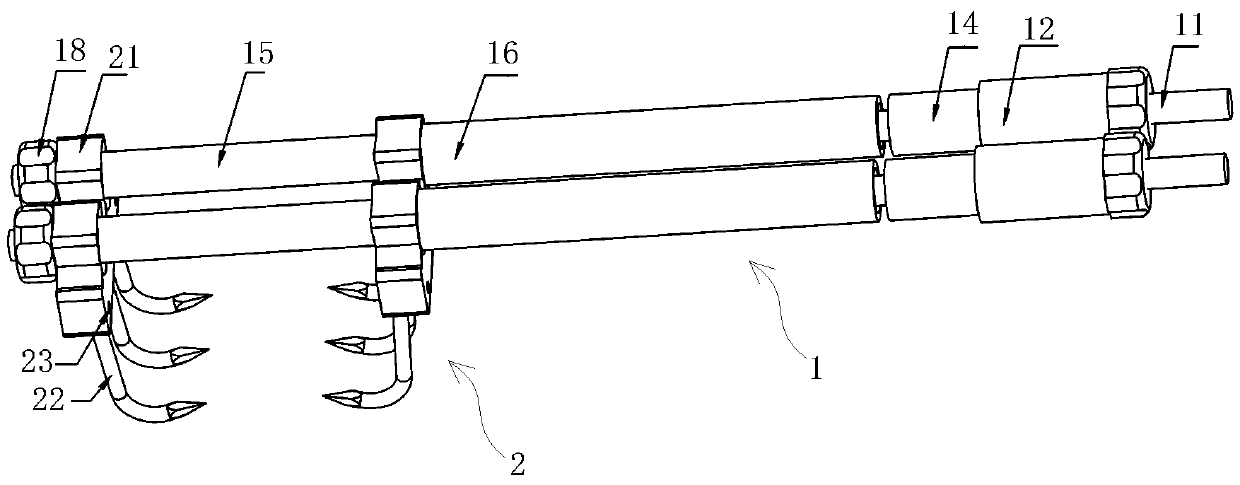

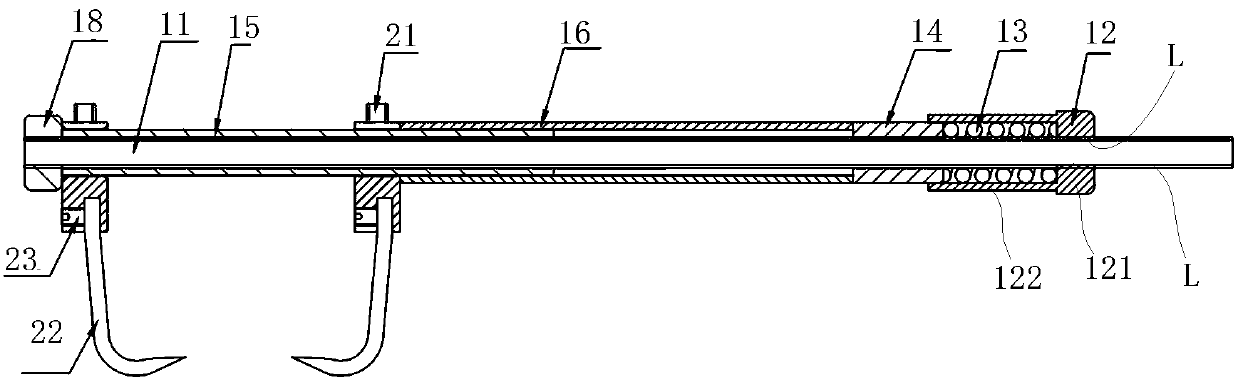

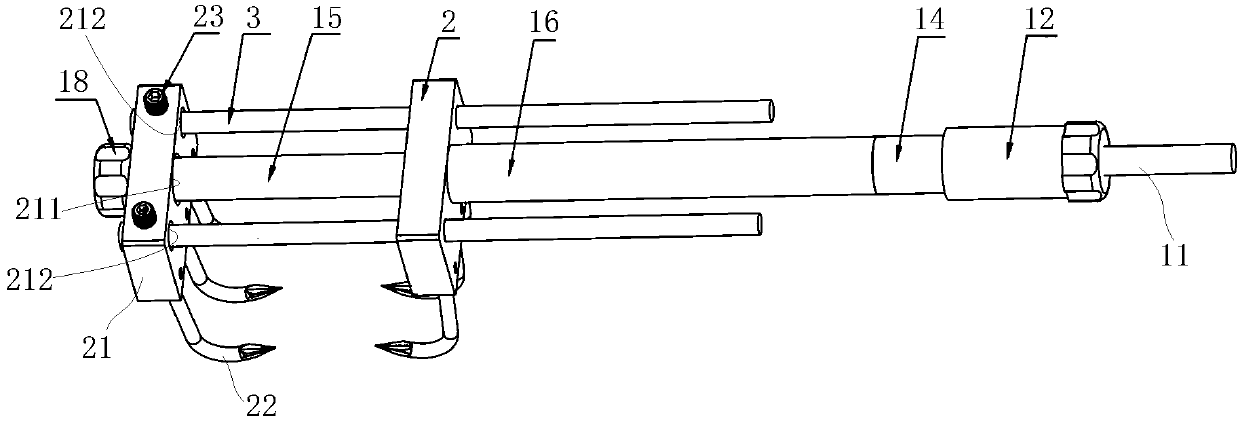

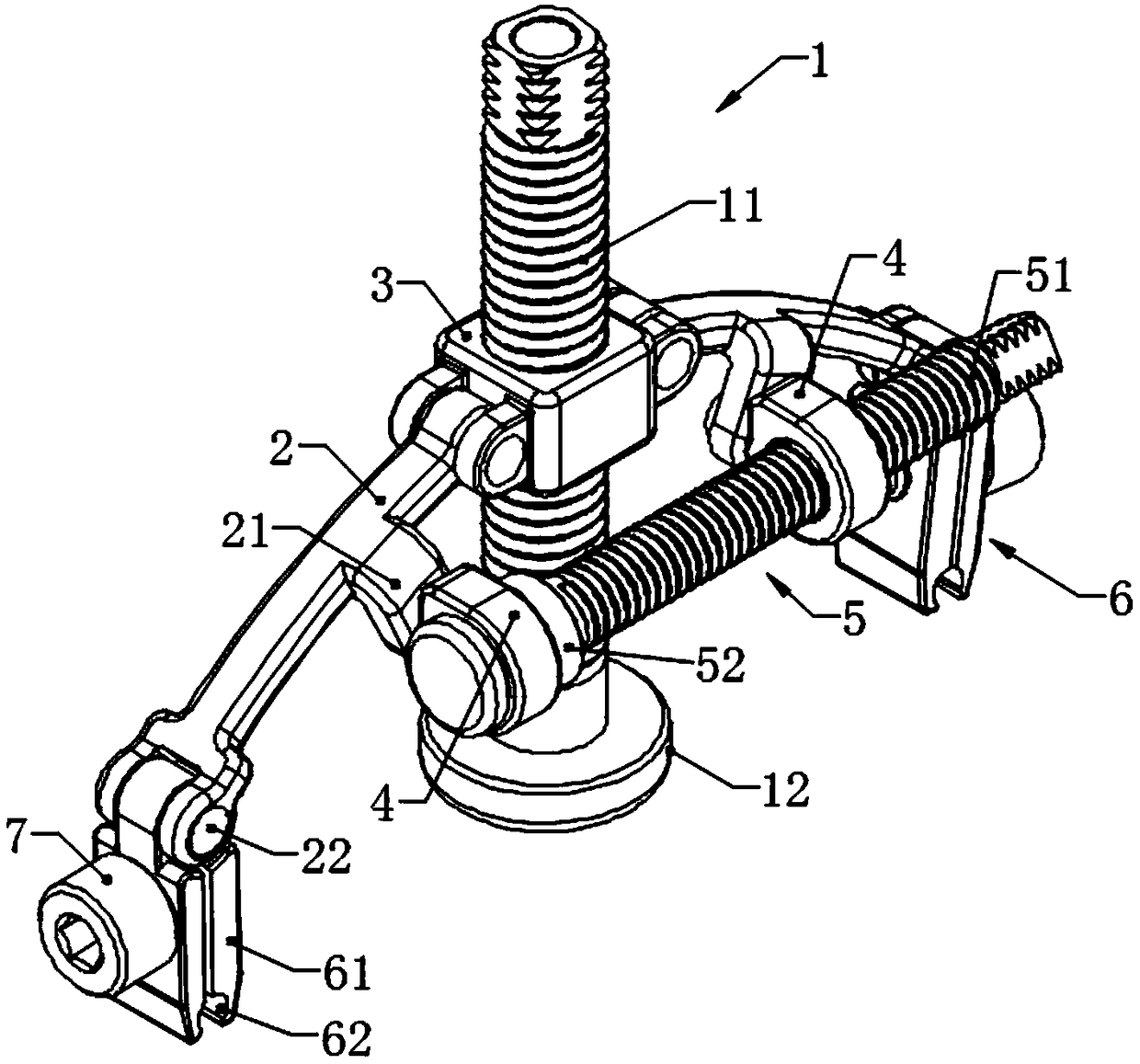

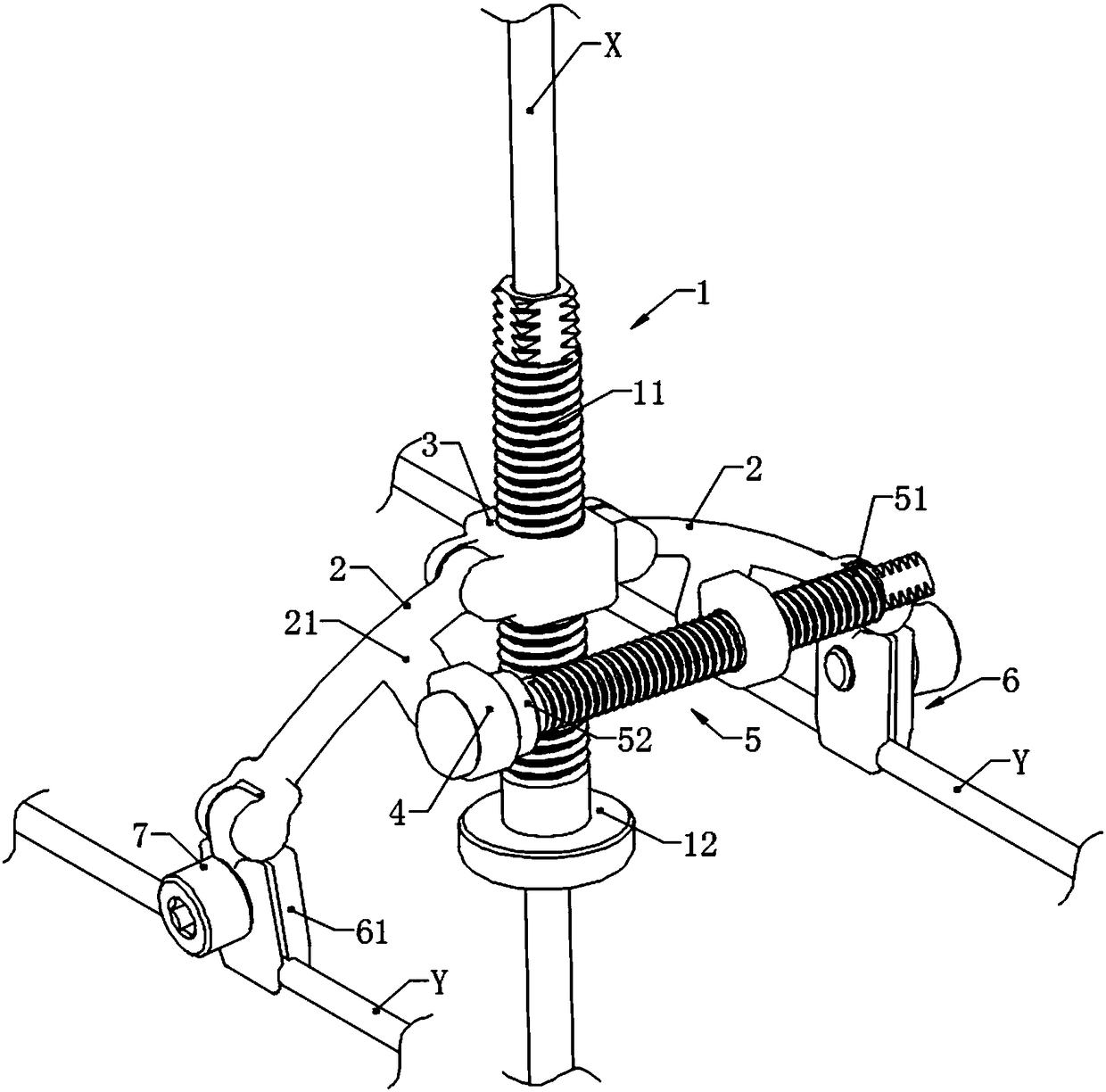

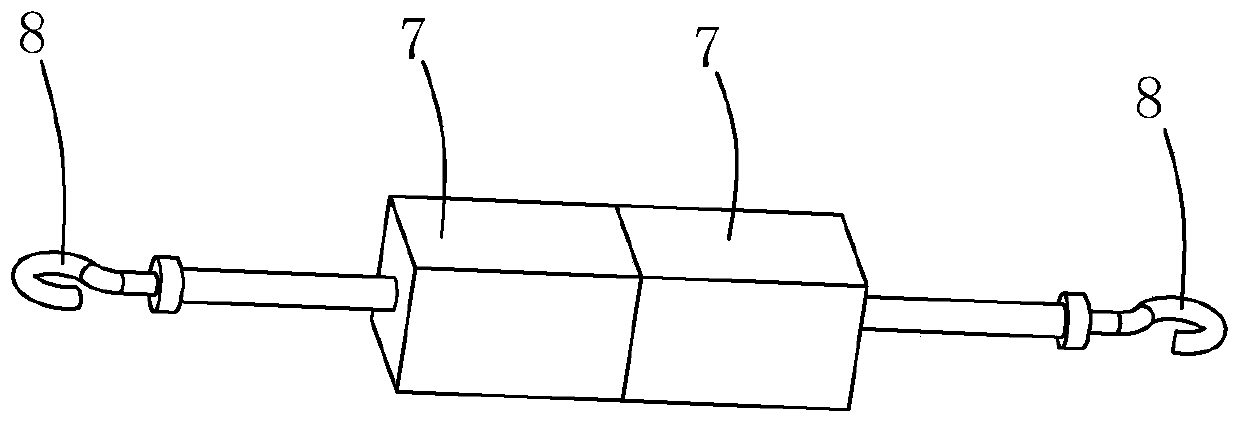

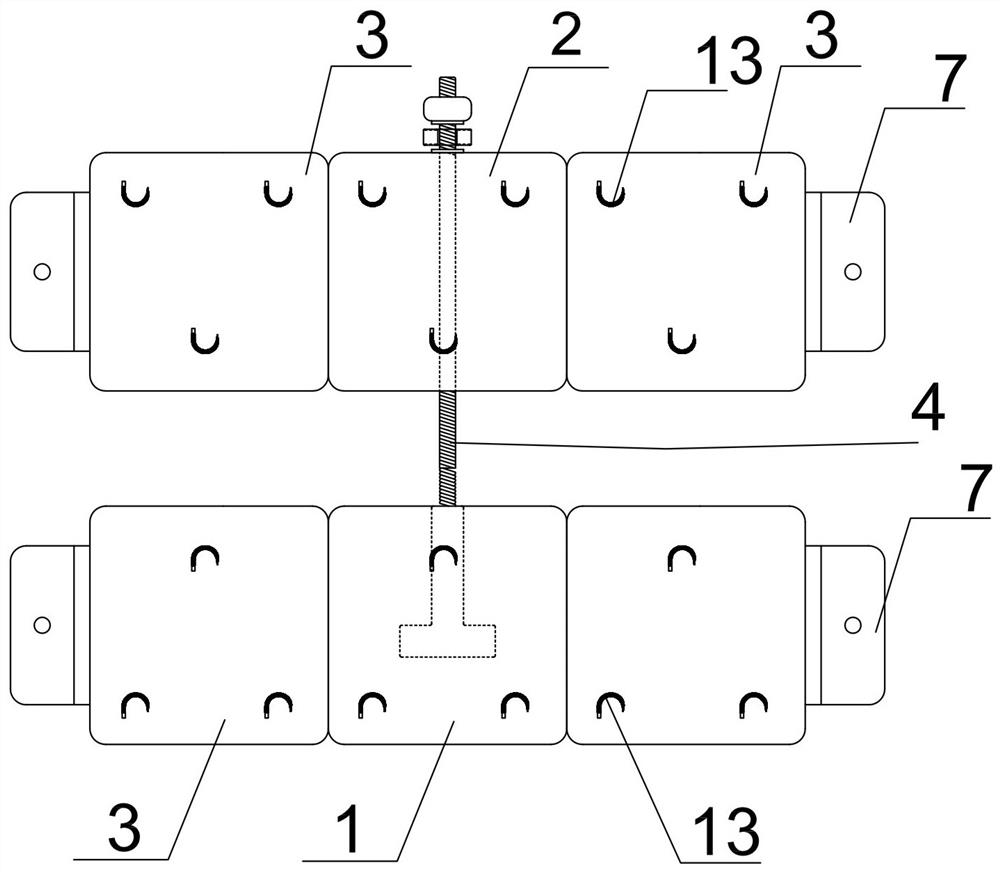

Row hook type skin stretch closure device

The invention provides a row hook type skin stretch closure device. The row hook type skin stretch closure device comprises adjusting assemblies and fixing hook devices, wherein each adjusting assembly comprises a threaded rod, a pressure adjusting member, a pressure adjusting spring, a sliding casing pipe and a fixing nut, each fixing hook device comprises a fixing hook body part and multiple hooks arranged on the corresponding fixing hook body part, the upper portions of the fixing hook body parts are transversely provided with circular holes, each fixing nut and the corresponding pressure adjusting member are rotationally arranged at the two ends of the corresponding threaded rod respectively, each pressure adjusting spring and the corresponding sliding casing pipe sequentially sleeve the corresponding threaded rod, each pressure adjusting member, the corresponding pressure adjusting spring and the corresponding sliding casing pipe are in pushing cooperation in sequence, each threaded rod between the corresponding sliding casing pipe and fixing nut is sleeved with an inner sleeve and an outer sleeve, each outer sleeve sleeves the corresponding inner sleeve, the two fixing hook devices slidably sleeve the inner sleeves through the circular holes and are in pushing cooperation with the outer sleeves and the fixing nuts in the axial direction respectively, and the outer sleevesare in pushing cooperation with the sliding casing pipes; or the inner sleeves are not arranged, and the middles of the threaded rods are provided with smooth rod sections, thereby ensuring that therow hook type skin stretch closure device cannot be jammed when the fixing hook devices slide.

Owner:宋若怡

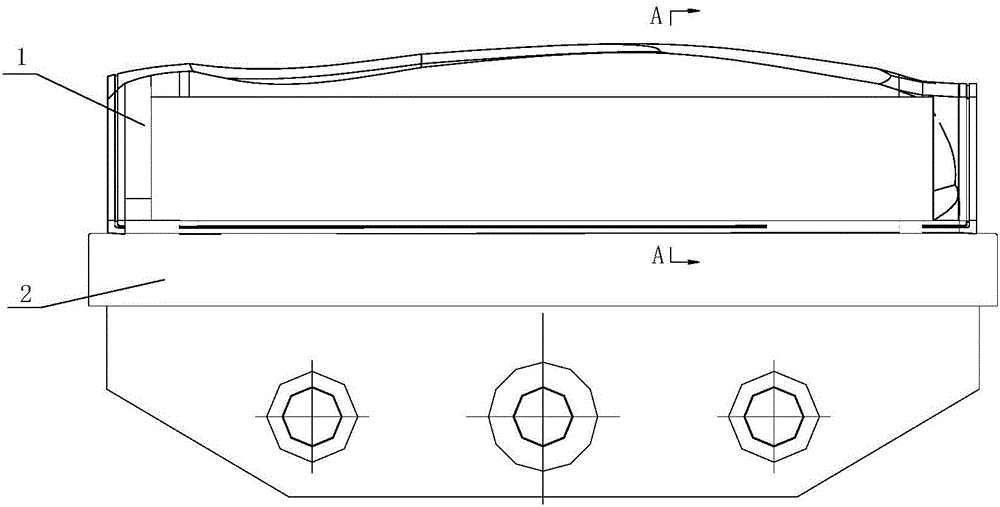

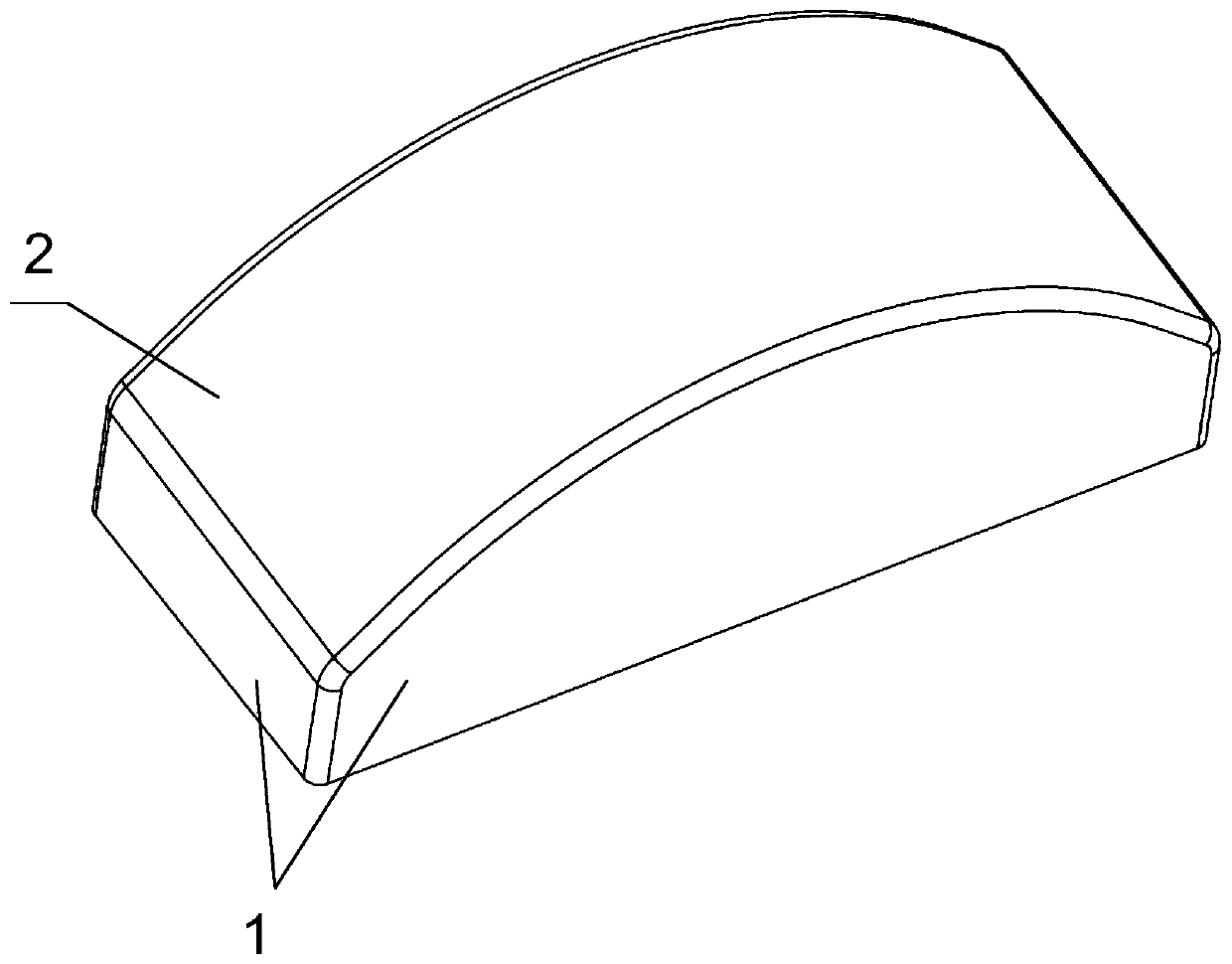

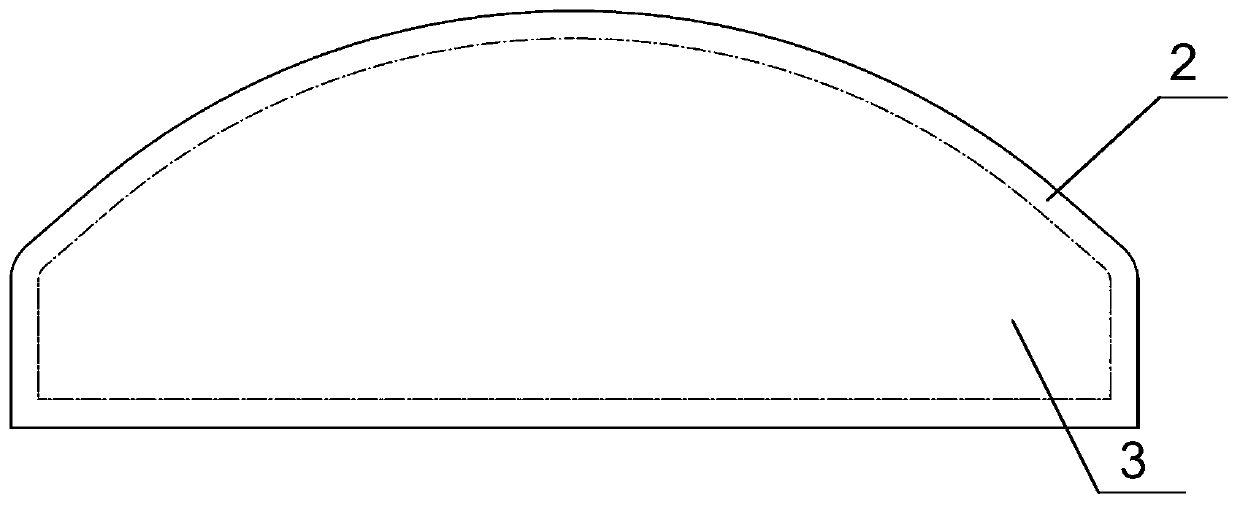

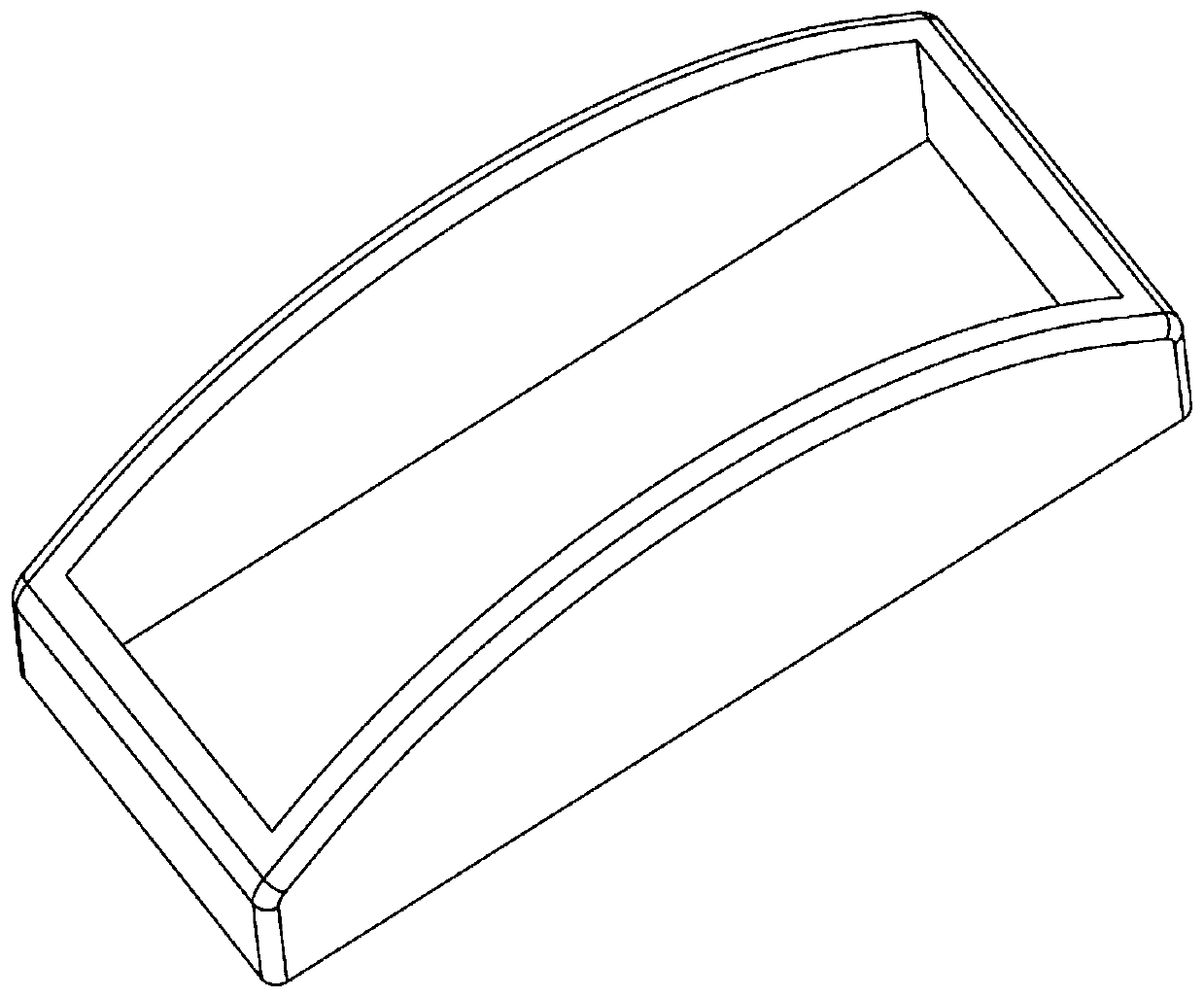

Skin stretch forming die and manufacturing method thereof

The invention belongs to the technical field of technological equipment designing and manufacturing, and particularly relates to a skin stretch forming die and a manufacturing method thereof. The skinstretch forming die comprises a wooden structure frame, an epoxy resin-talcum powder surface and an epoxy resin-glass bead filling body; and the wooden structure frame is arranged at the periphery and the bottom face of the skin stretch forming die, the epoxy resin-talcum powder surface is arranged on the top face of the skin stretch forming die, the wooden structure frame and the epoxy resin-talcum powder surface form a hollow space, and the hollow space is filled with the epoxy resin-glass bead filling body. According to the skin stretch forming die and a manufacturing method thereof, the technological operation processes are simple, filling material sources are wide, the relative cost is low, the relative weight is low, and machining and using are convenient in the skin part stretch forming process.

Owner:SHENYANG AIRCRAFT CORP

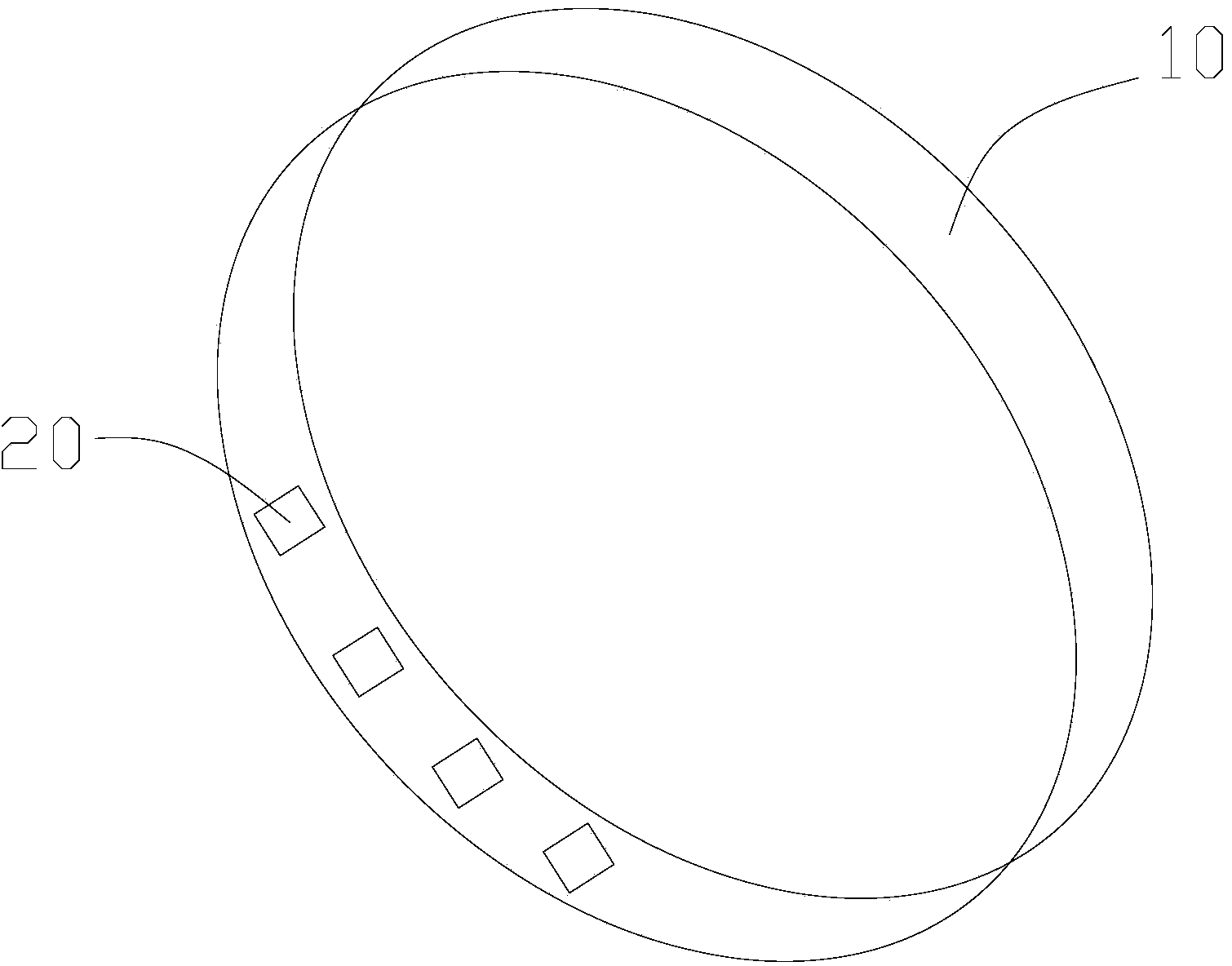

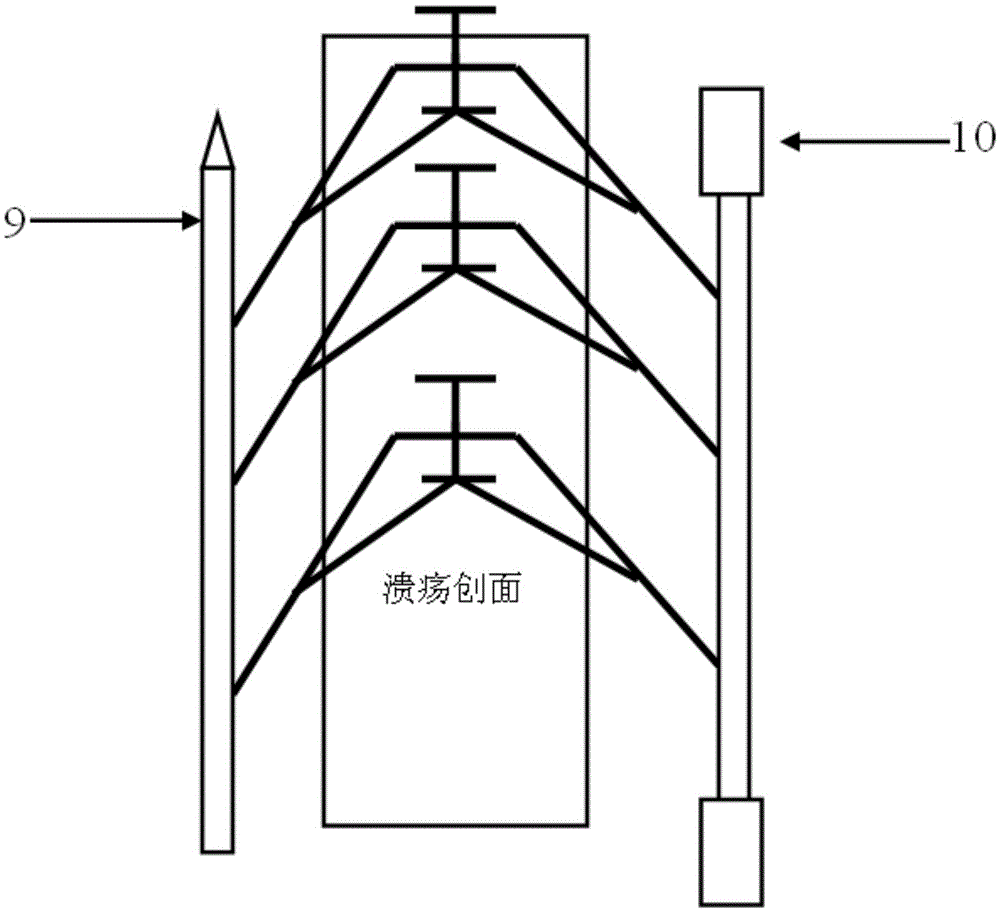

Intelligent skin stretching device

PendingCN111150499ARealize automatic pullingSafe surgery effectDiagnosticsSurgeryWound skinSkin stretching

The invention discloses an intelligent skin stretching device, and belongs to the technical field of medical instruments. The intelligent skin stretching device is composed of two hook elements and anelectric device which is controlled by an intellectualized program. Two specific embodiments are disclosed. The intelligent skin stretching device has the advantages that the intelligent skin stretching device is provided with the electric device which is controlled by the intellectualized program, thus traditional manual operation is replaced, and automatic stretching of skin on two sides of wounds and precise control are achieved, so that an operation effect which is more efficient, safer and better is obtained. The skin stretching device can turn large-spacing high-tension wounds (cuts) into small-spacing low-tension wounds (cuts), direct suturing is achieved, and the purpose of primary closure is achieved.

Owner:上海迪派生物科技有限公司

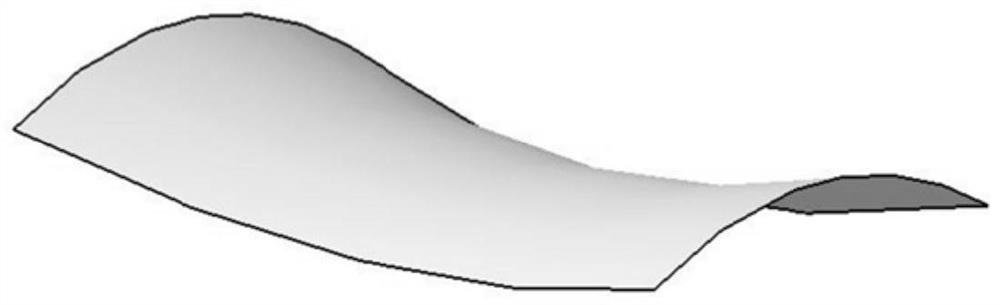

Method for segmented stretch forming molding of 2000-series aluminum alloy skin

The invention relates to a method for molding aeronautic sheet metal parts, belongs to the technical field of aeronautic manufacturing and provides a method for segmented stretch forming molding of 2000-series aluminum alloy skin. The method for segmented stretch forming molding of the 2000-series aluminum alloy skin comprises the following steps that firstly, according to the radian characteristics of the skin stretch forming die profile, the skin stretch forming die profile is divided into multiple areas of a first area, a second area and the like; secondly, two ends of skin are clamped by jaws of a stretch forming machine; and thirdly, stretch forming molding is conducted on the first area, the second area and the like of the skin in sequence according to working procedures so that profiles, located in the first area, the second area and the like, of the skin and a skin stretch forming die are fitted completely, and namely, stretch forming molding of the skin is completed. The method for segmented stretch forming molding of the 2000-series aluminum alloy skin has the following advantages that firstly, the stretch forming molding uniformity is improved, and defects such as slip lines and cracks are prevented from being generated in partial areas of the skin; and secondly, the shape radian conformity after skin stretch forming is improved so that project drawing requirements are met by the shape radian conformity, and then the skin quality is improved so that more outstanding aircraft pneumatic shape can be achieved.

Owner:JIANGXI HONGDU AVIATION IND GRP

Method for forming complex double-curvature skin part

ActiveCN113523148AReduce areaSolve the biggest difficultyAircraft componentsSustainable transportationMechanical engineeringWrinkle

The invention discloses a method for forming a complex double-curvature skin part. The method comprises the following steps: firstly forming a double-curvature part in a range of 1 / 5-1 / 3 of the bottom of the part through a pre-forming die by adopting an active liquid-filling forming mode, and forming a side wall of the double-curvature part and local characteristics on the side wall through a final forming die by adopting a passive liquid-filling forming mode. According to the method, in the first step, the active liquid-filling forming mode is adopted, the stress state of the skin part in the skin drawing forming process is changed, and the problems that in the drawing process, stress is uneven, and the top is broken and a suspended area wrinkles due to the fact that the size of the cross section is greatly changed are solved; and in the second step,the active liquid-filling forming mode is adopted, soft draw beads are formed in the forming process so that wrinkling can be restrained, and meanwhile local complex characteristics such as pits and protrusions of the side wall of the double-curvature skin part can be formed.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Skin stretch combination tool

The invention discloses a skin stretch combination tool. The tool comprises a bracket, horizontal regulating mechanisms mounted at four corners in the bottom of the bracket, a first skin clamp mounted at a first end of the bracket, a second skin clamp mounted at a second end of the bracket, a sliding block mounted at the second end of the bracket in a sliding manner and connected with the second skin clamp through a connecting rod, and a jack mounted at the second end of the bracket, wherein a push rod of the jack is connected with the sliding block to push the sliding block to move. The skin stretch combination tool can eliminate deformation and bulging phenomenon of a skin after the welding with a skeleton, and can eliminate deformation of the skin due to temperature difference change after the welding, so that the surface of a carriage is smooth and beautiful, and the quality of an automobile body is largely improved. The tool is suitable for skin stretch in automobile production enterprises, and also can be applied in other fields, such as decoration. The production cost of the tool is low; and the size and the plate thickness of the tool are not restricted.

Owner:衡阳泰豪通信车辆有限公司

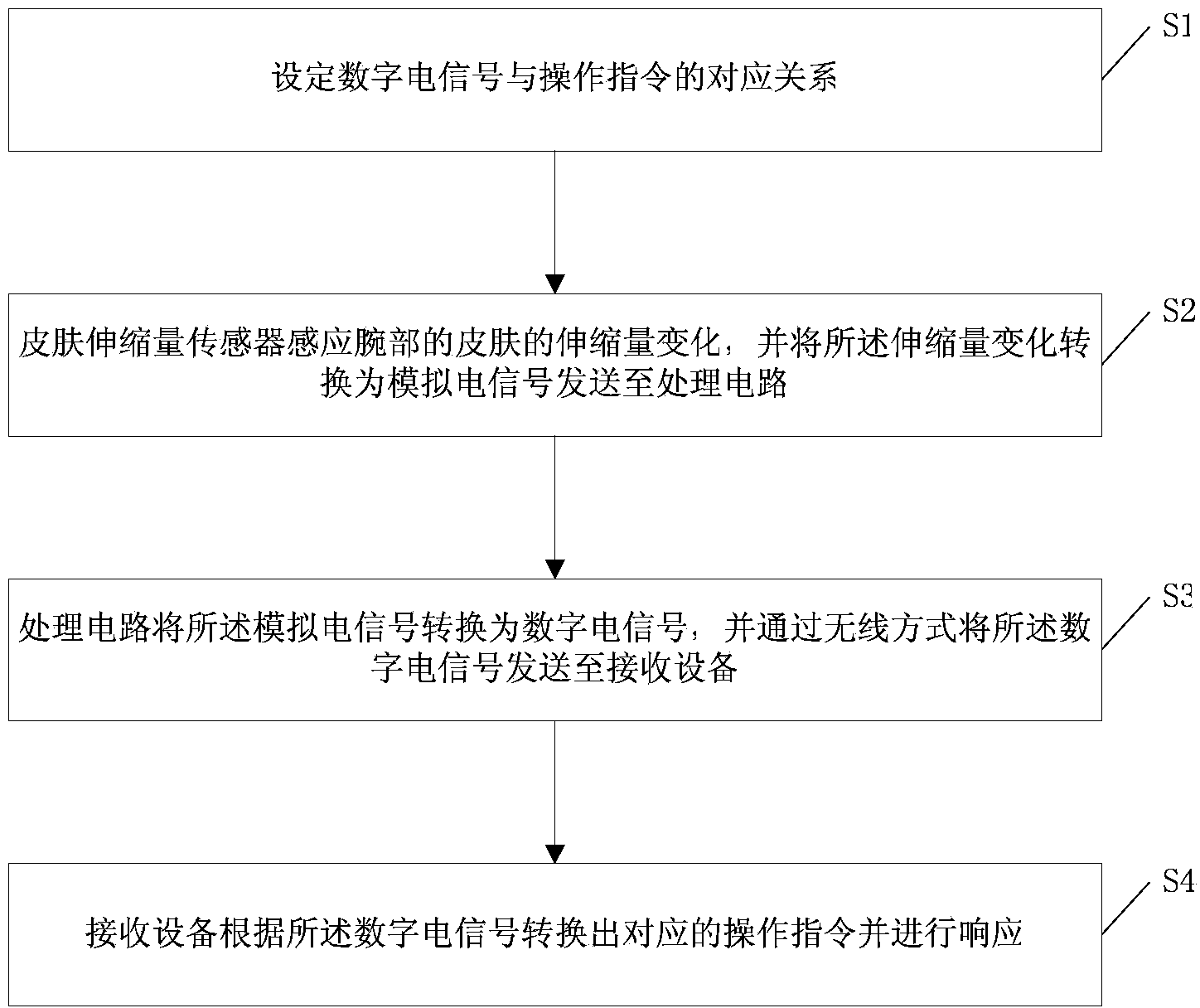

Operational order input system and operational order input method

InactiveCN104035579AImprove versatilityInput/output processes for data processingSimulationTouchscreen

The invention relates to an operational order input system and an operational order input method. The method comprises the following steps that a skin stretching amount sensor induces stretching amount change of skin of a wrist, and converts the stretching amount change into analog electric signals which are transmitted to a processing circuit; the processing circuit converts the analog electric signals into digital electric signals which are transmitted to receiving equipment in a wireless mode or a wired mode; and the receiving equipment converts the digital electric signals into corresponding operational orders and responds. A user does not need to operate intelligent equipment by using a mouse, a keyboard, a touch screen and the like, and can operate the intelligent equipment by body movement only. The operational order input system and the operational order input method are quite convenient.

Owner:何东波

Large aircraft skin blank structure and skin stretching forming method

ActiveCN110695180AImprove molding uniformityQuality improvementFuselage bulkheadsAviationSkin stretching

The invention relates to an aviation sheet metal part and a forming method thereof, belongs to the technical field of aeronautical manufacturing, and discloses a large aircraft skin blank structure and a skin pull stretching method. According to the large aircraft skin blank structure, the end of a skin blank is provided with a structure protruding outwards in the stretching direction. A skin is of the above skin blank structure. The skin stretching forming method comprises the following steps that firstly, a jaw of a stretching machine is lifted up by a certain angle and is bent, and the twoends of the skin blank are clamped in the jaw of the stretching machine; secondly, the jaw of the stretching machine oppositely moves in the horizontal direction, and the skin blank is warped; thirdly, the height of the jaw of the stretching machine is reduced, and the skin blank is in contact with the face of a skin stretching mold; and fourthly, the jaw of the stretching machine does stretchingmotion in the direction away from the skin stretching mold in the horizontal direction, and the skin blank and the face of the skin stretching mold are completed stretched and attached. The large aircraft skin blank structure and the skin pull stretching method have the following advantages that the skin quality is improved, and therefore the more excellent aircraft pneumatic appearance is achieved.

Owner:JIANGXI HONGDU AVIATION IND GRP

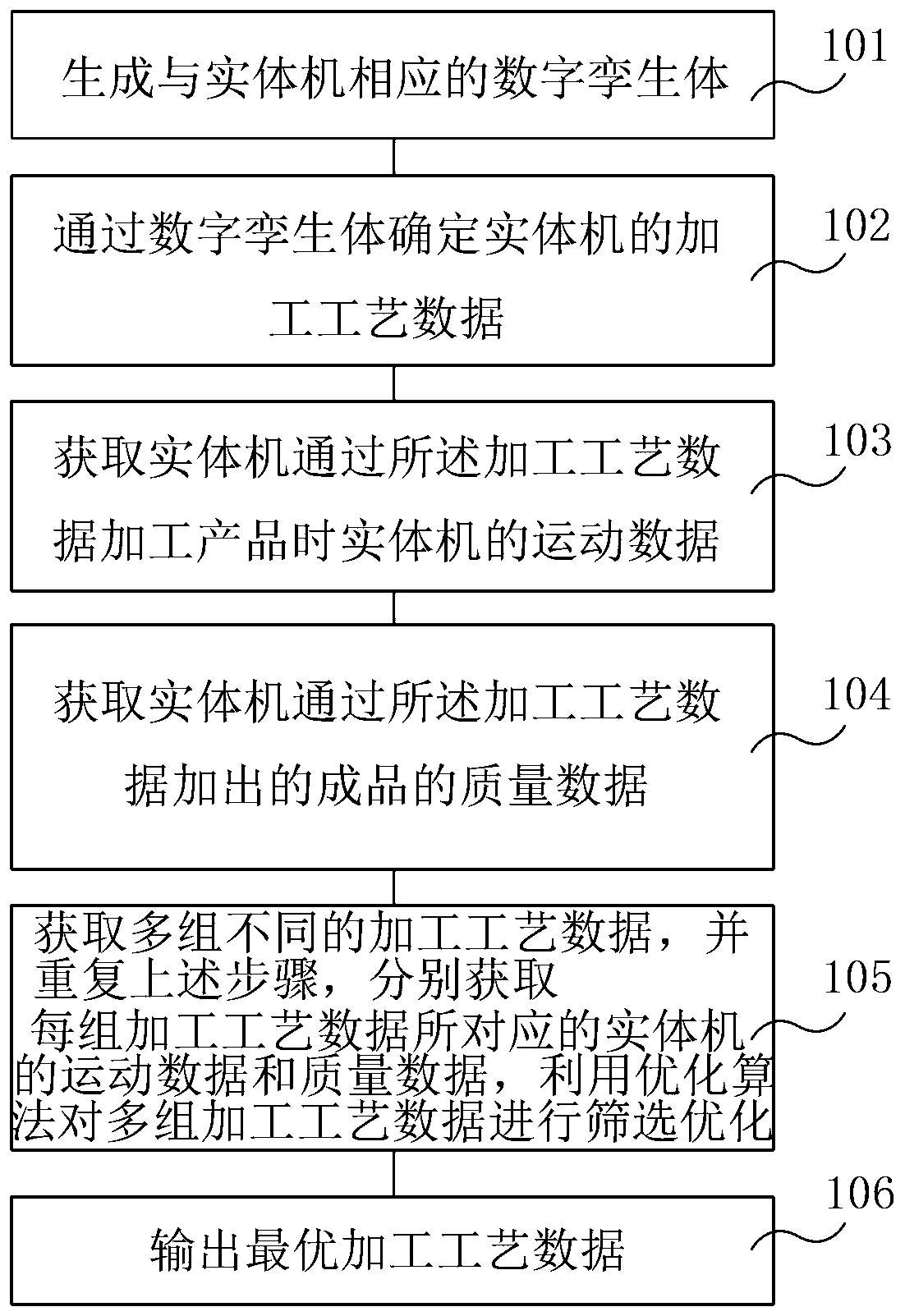

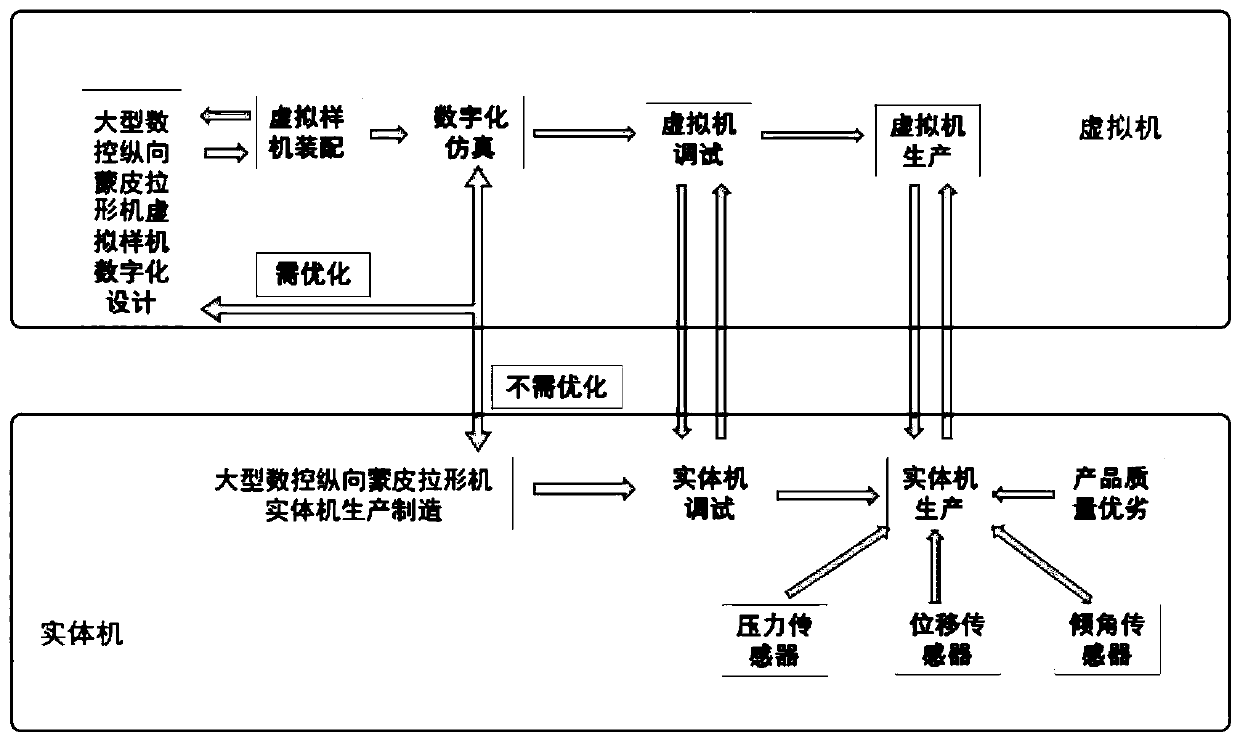

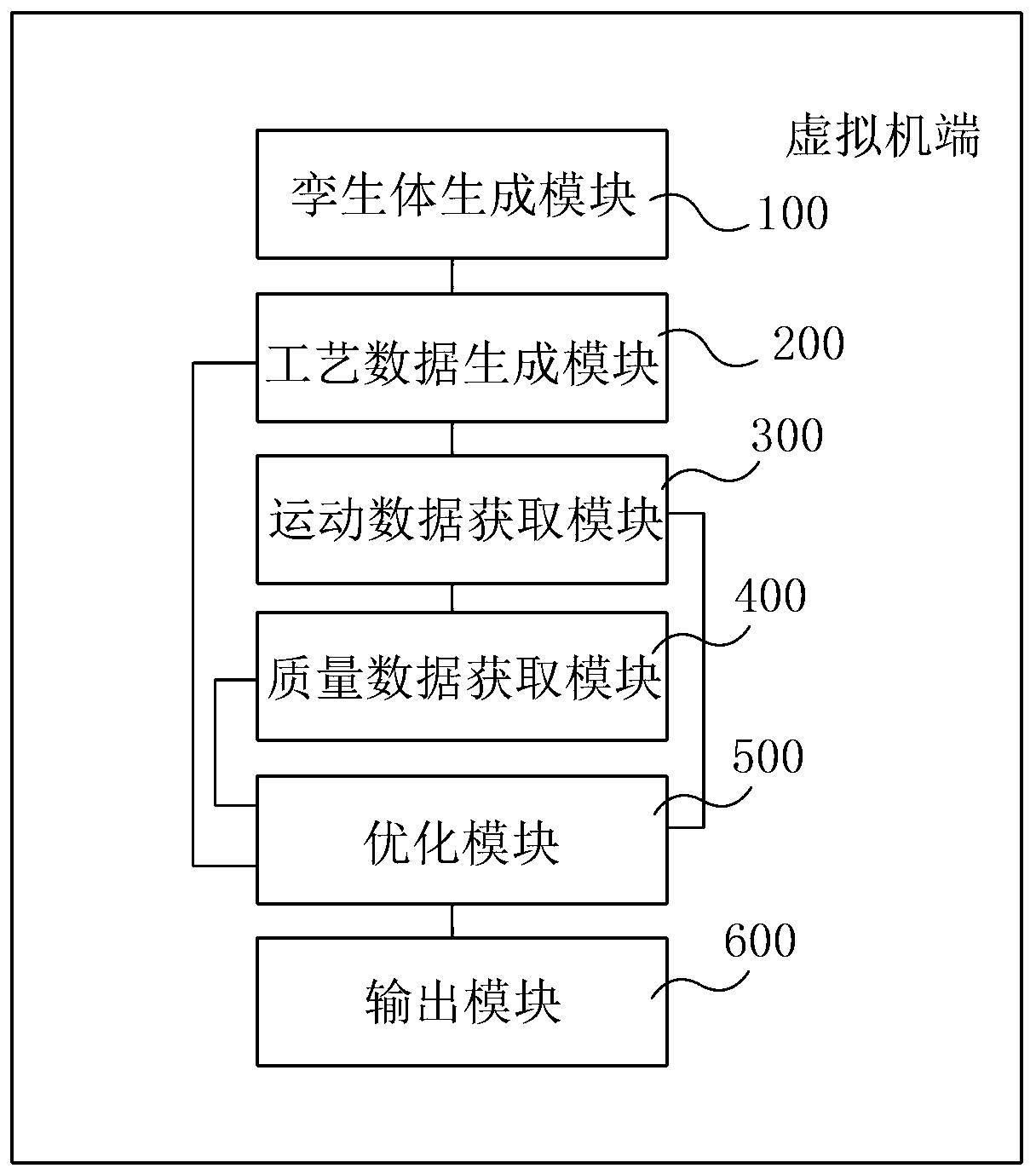

Digital twinning method and device for numerical control skin stretch-forming machine

PendingCN111125879AFull two-way communicationOptimizing process dataDesign optimisation/simulationSkin stretchProcess engineering

The invention belongs to the technical field of stretch forming, and relates to a digital twinning method of a numerical control skin stretch forming machine, which is used for a virtual machine end and comprises the following steps of: generating a digital twinning body corresponding to a physical machine; determining processing technology data of the entity machine through the digital twinborn body; acquiring motion data of the physical machine when the physical machine processes the product through the processing technology data; obtaining quality data of a finished product finally obtainedwhen the physical machine processes the product through the processing technology data; acquiring a plurality of groups of machining process data; adopting an optimization algorithm to screen and optimize the multiple sets of machining process data, wherein the screening optimization is carried out according to the motion data of the entity machine corresponding to each group of processing technology data and the quality data of the finished product; synchronizing the motion data of the entity equipment in production to the virtual machine end, so as to establish complete bidirectional communication between the digital twinborn body and the entity machine, and obtaining more optimized processing technology data through screening optimization.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

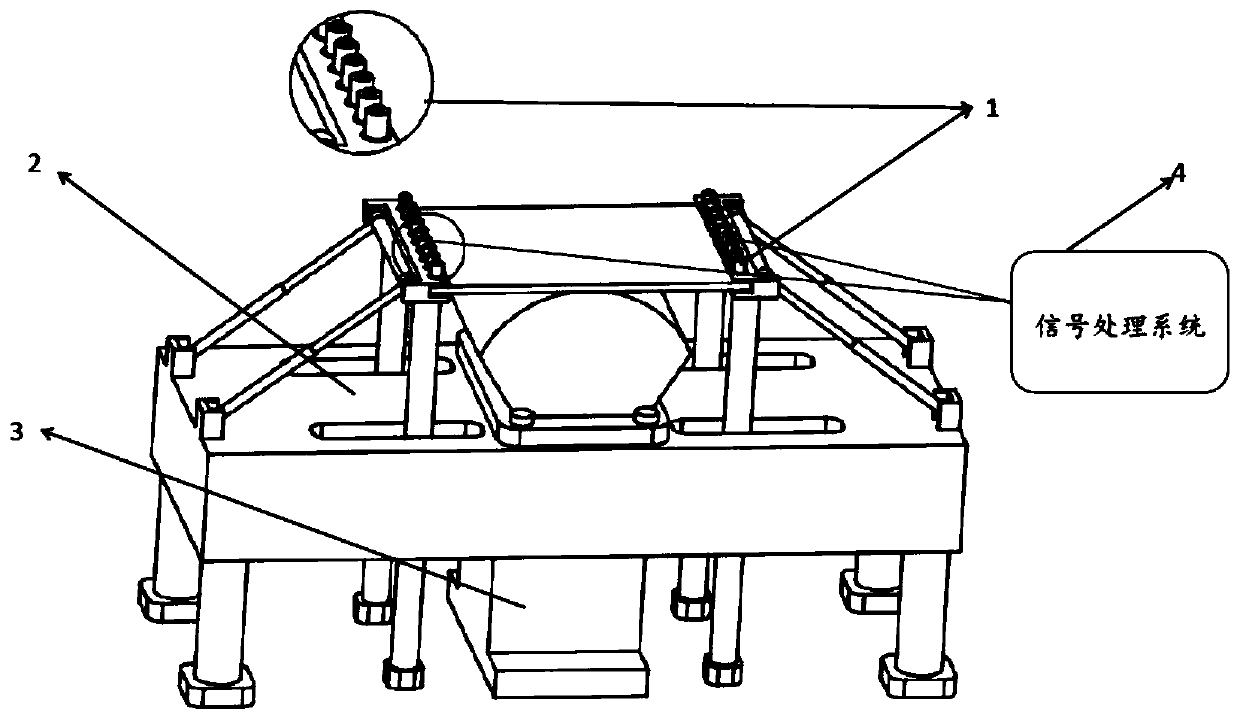

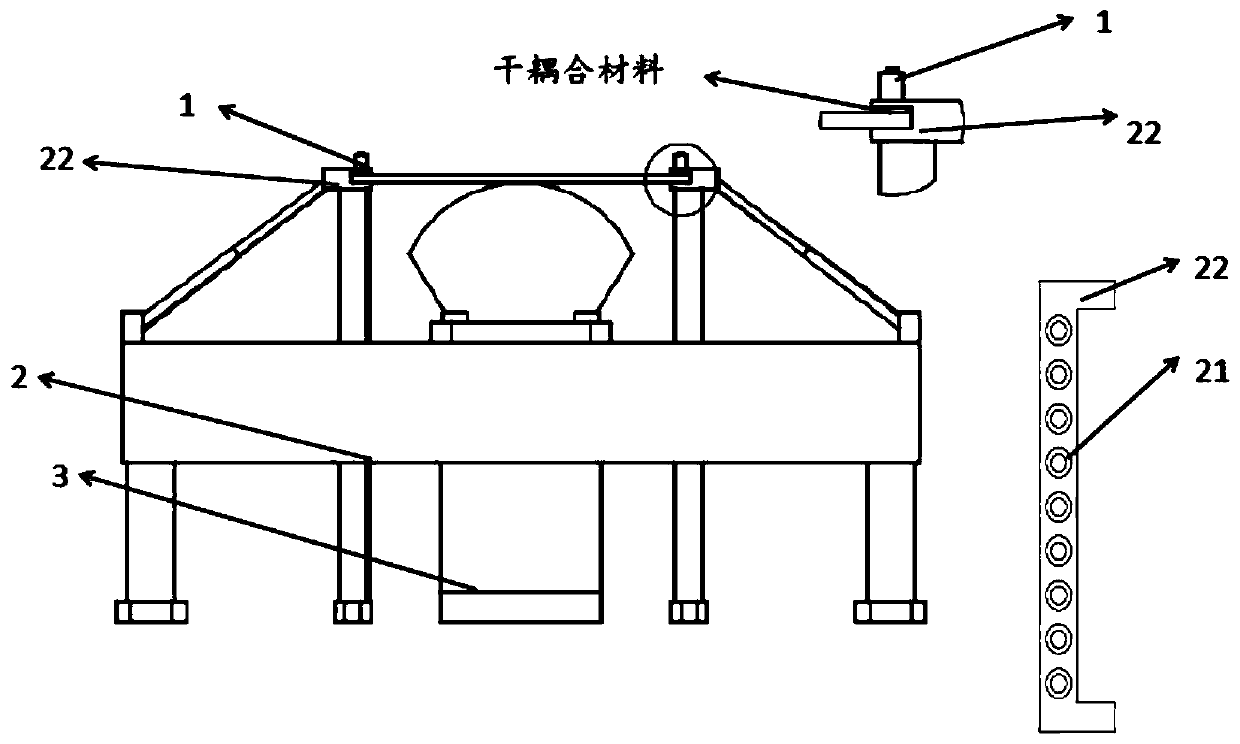

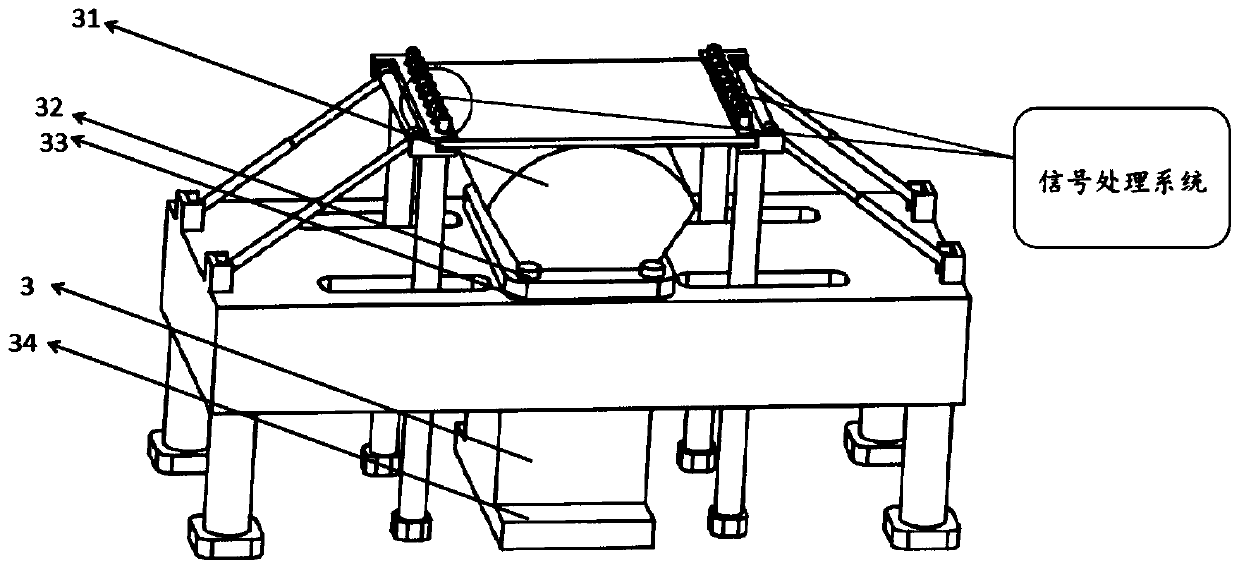

Skin stretching defect online detection device

ActiveCN110508659AReduce processing time cycleIncrease productivityAircraft componentsMetal working apparatusSensor arrayAcoustic emission

The invention discloses a skin stretching defect online detection device, relates to the field of sheet forming, and aims to detect and locate the defects of skin stretching of an aircraft in real time. The device comprises acoustic emission sensor arrays, stretching equipment and a signal processing system; the stretching equipment is provided with groove holes and used for stretching skin; the acoustic emission sensor arrays are arranged in the groove holes and are used for detecting elastic wave signals generated by the skin during the process of stretching the skin by the stretching equipment; the acoustic emission sensor arrays transmit the elastic wave signals to the signal processing system; and the signal processing system analyzes the elastic wave signals through VMD decomposition, and when parameter values of the elastic wave signals are larger than normal threshold values, an alarm signal is sent to remind a user that the skin has defects.

Owner:SICHUAN UNIV

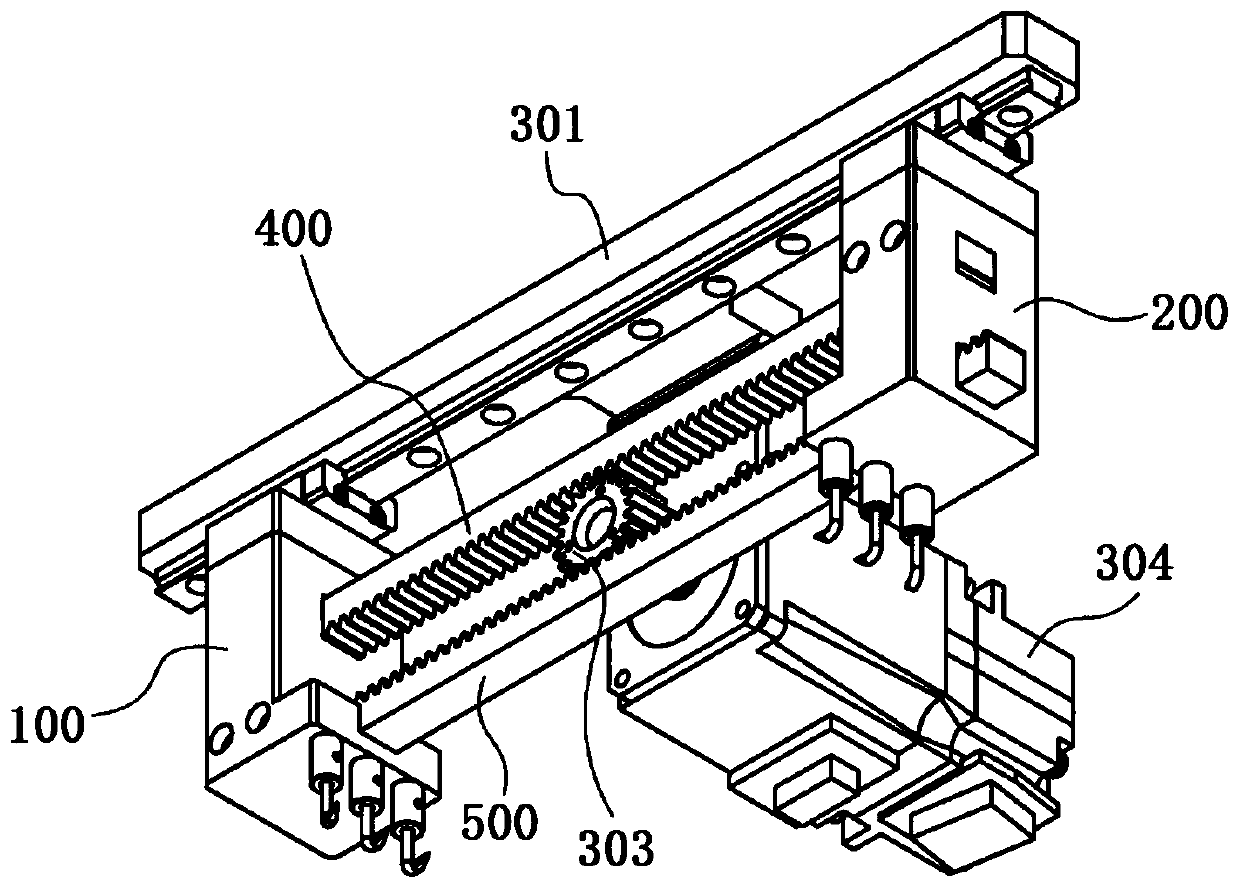

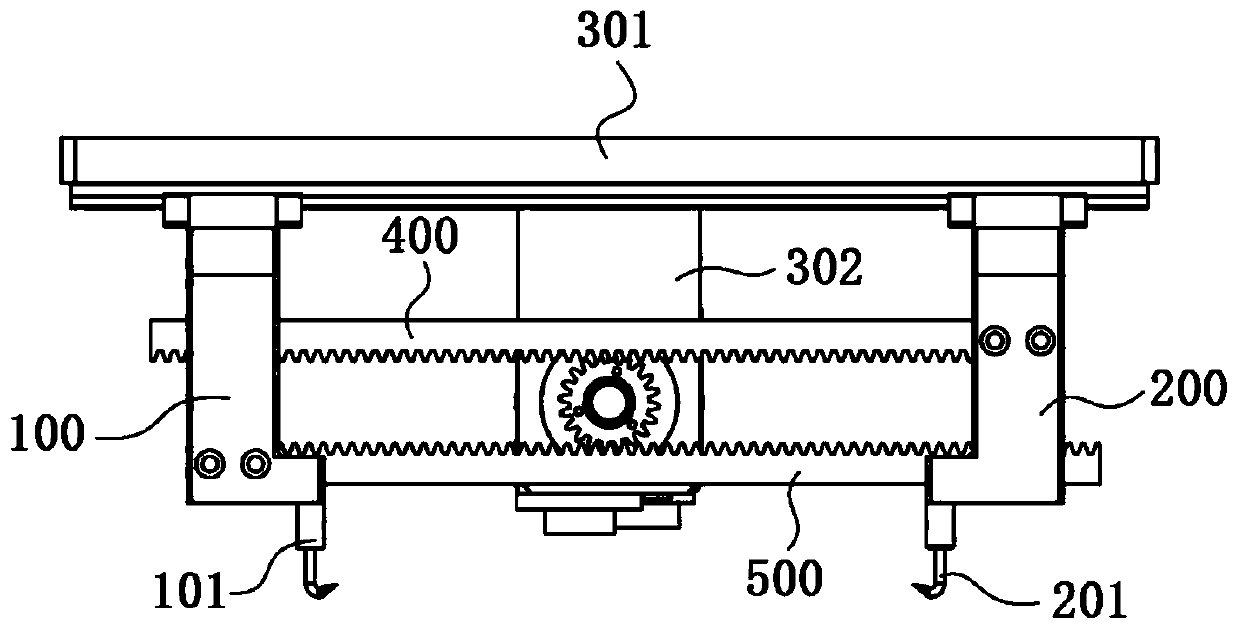

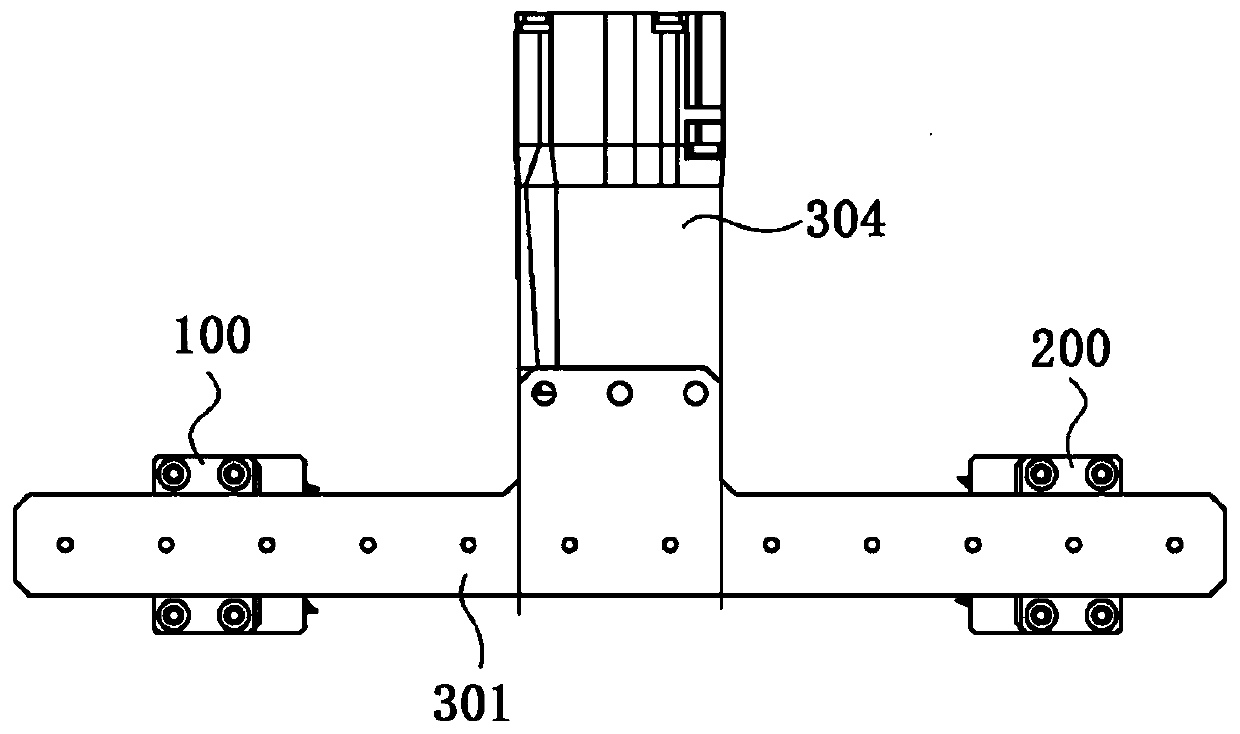

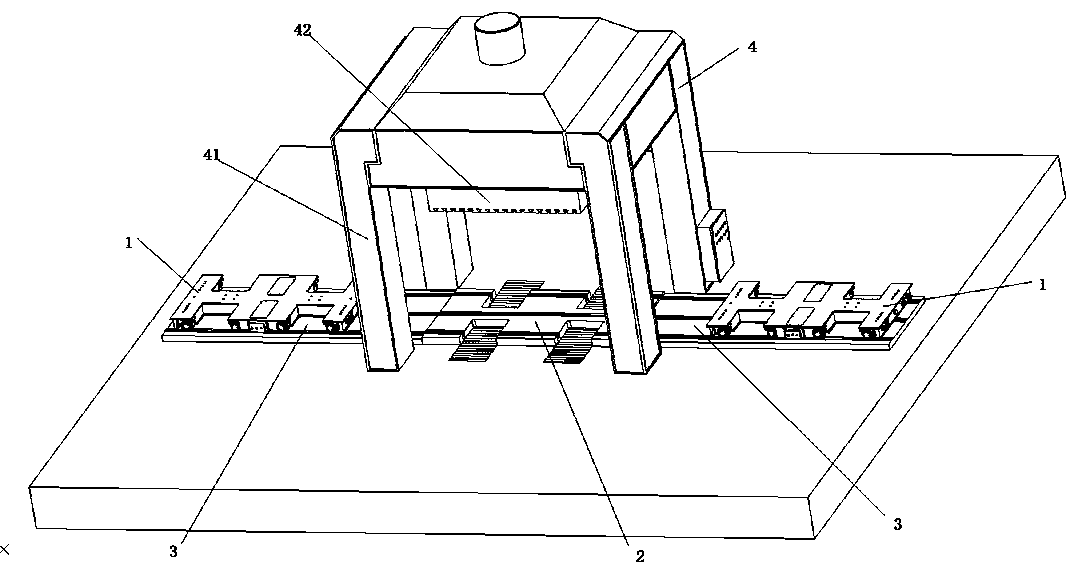

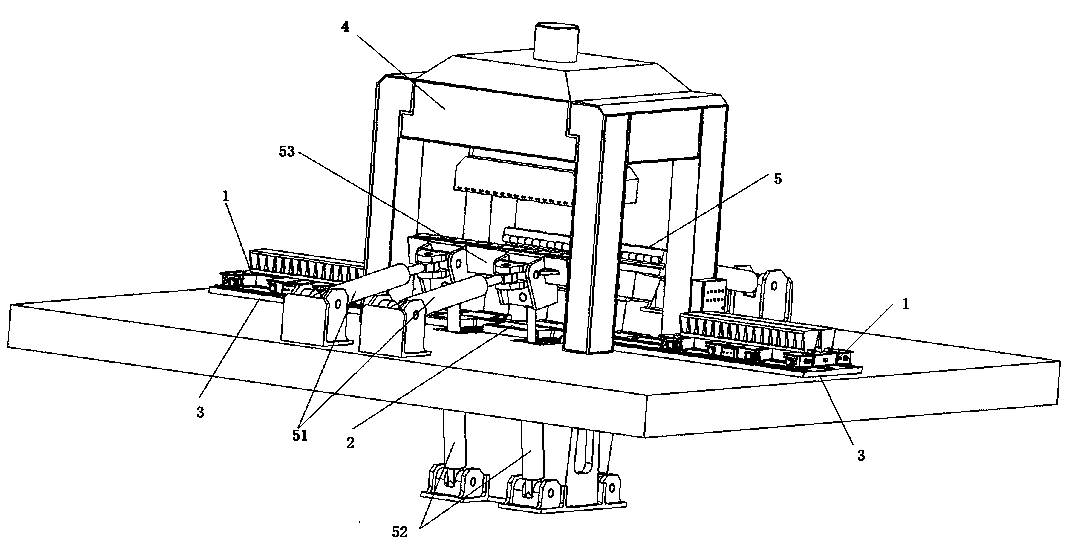

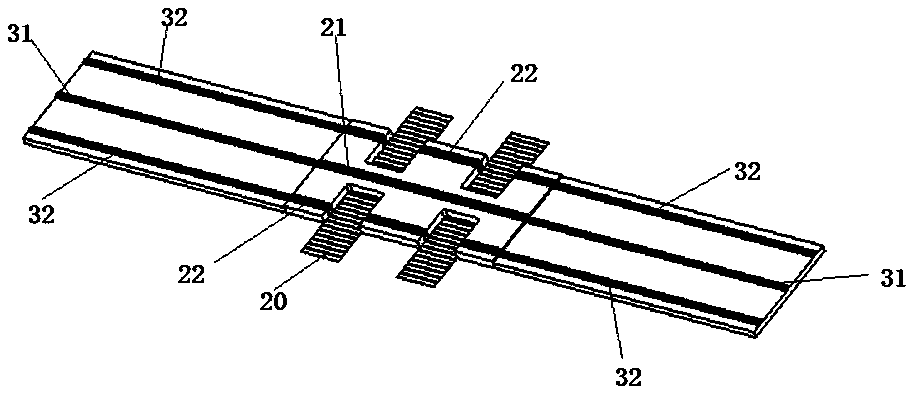

Mould quick replacing system of FET 1200 type skin stretching former

PendingCN110625014AReduce downtimeImprove work efficiencyAircraft componentsShaping toolsManufacturing technologyEngineering

The invention discloses a mould quick replacing system of an FET 1200 type skin stretching former, and relates to the technical field of aircraft skin fabrication. The mould quick replacing system comprises a mould replacing rail device and two movable workbenches; the two movable workbenches are movably arranged on a mould replacing rail; the mould replacing rail device comprises a working area rail device and two preparation area rail devices; the two preparation area rail devices are correspondingly connected with the two ends of the working area rail device; the working area rail device and the movable workbenches are overlooked to be word-king-shaped; and the sizes of word-king-shaped gaps of the working area rail device and the movable workbenches are adaptive. The mould quick replacing system is high in automation degree, moulds are quick and convenient to replace, and the machining accuracy of skin parts is ensured more easily.

Owner:SOUTHWEST JIAOTONG UNIV

Skin stretching closer

The invention provides a skin stretching closer. The skin stretching closer comprises a base body, a compressor device, a contraction mechanism and needle clamps, wherein the compressor device is arranged on the base body, can be axially adjusted relative to the base body, and comprises a compressing plate used for pressing the skin in the wound surface, the contraction mechanism comprises a pairof connecting rods respectively hinged to the opposite side face of the base body and a pair of adjusting pieces connected with the connecting rods, and the adjusting pieces strut or gather the pair of connecting rods; the needle clamps are arranged at the tail ends of the needle clamps and comprise clamps used for clamping needles and locking pieces used for locking the clamps. The skin in the wound surface is pressed by the compressing plate of the compressor device, and it is avoided that muscles in the wound surface protrude and overflow; through the cooperation of the contraction mechanism and needle clamps, the wound surface is gradually strained to facilitate growth and closure of the wound surface.

Owner:陈卫

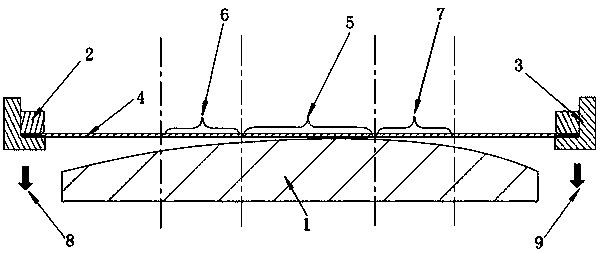

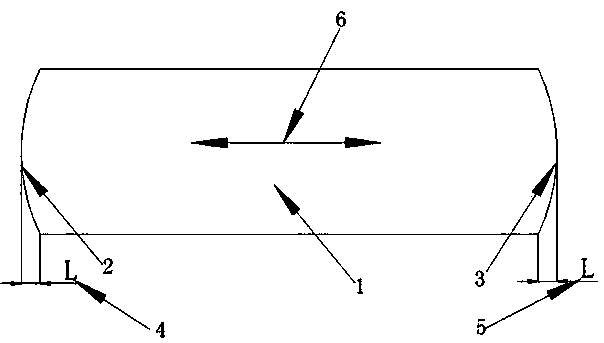

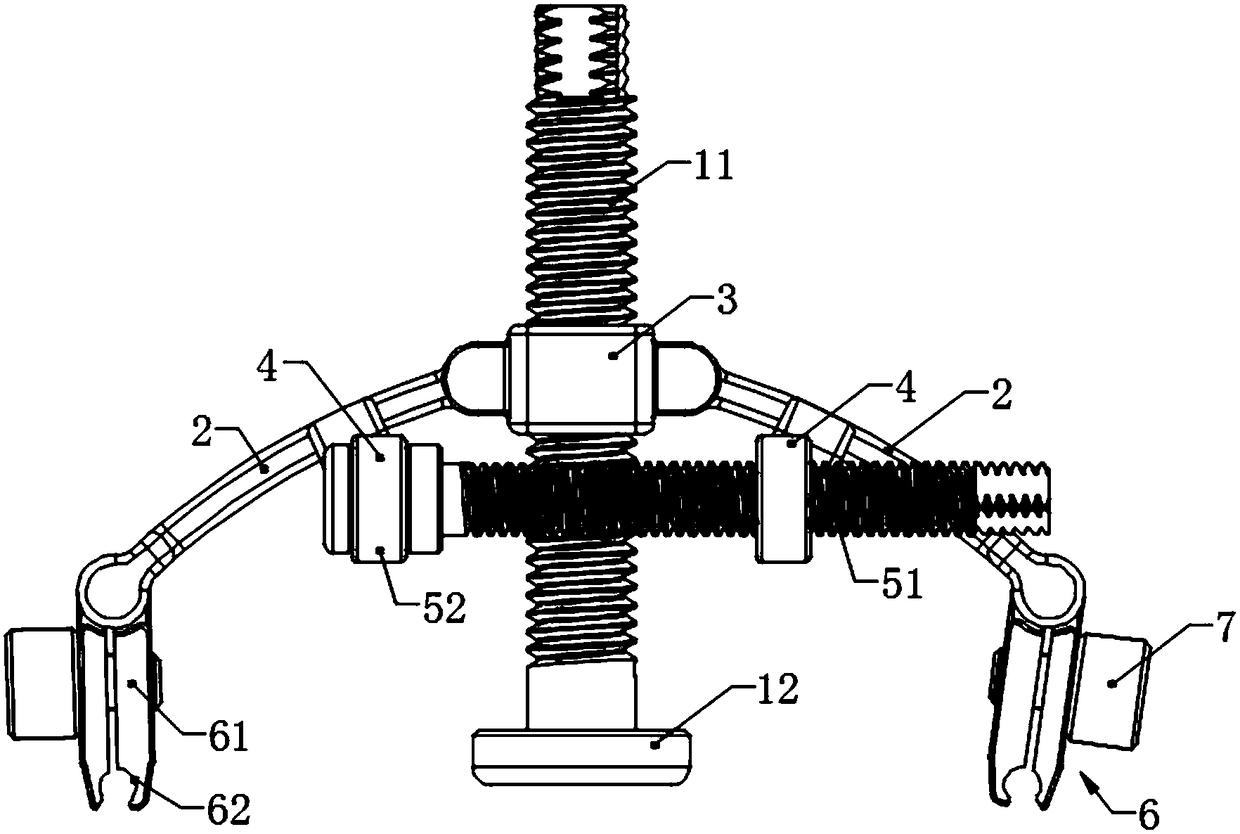

Movable heating skin stretch forming device and method

The invention relates to a movable heating skin stretch forming device and method. The device at least comprises a stretch forming die, stretch forming clamps, a movable heating unit and a pulling force immediate regulation unit, wherein the stretch forming die is fixed to a die installing seat; the stretch forming clamps are disposed on the two sides of the stretch forming die through ascending-descending clamp installing seats; the movable heating unit is disposed on the periphery of the stretch forming die and comprises a three-dimensional moving mechanism, heating elements and thermodetectors, the heating elements and the thermodetectors are installed on the three-dimensional moving mechanism; the three-dimensional moving mechanism can drive the heating elements and the thermodetectorsto move above and around the stretch forming die for heating and temperature collection during skin stretch forming; the heating elements and the thermodetectors are connected and are in data information transmission with the pulling-force immediate regulation unit; and the pulling-force immediate regulation unit is connected with the ascending-descending clamp installing seats and controls the ascending-descending clamp installing seats to ascend and descend.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

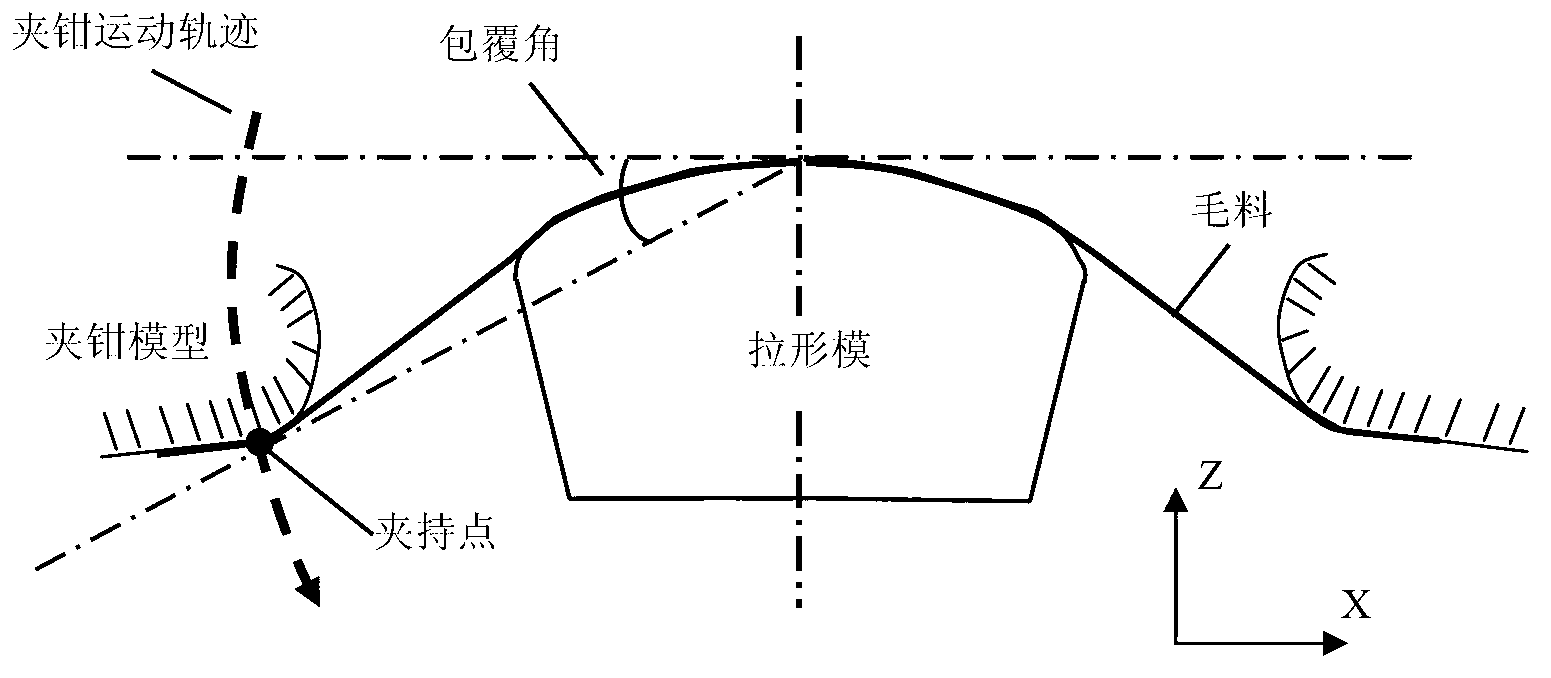

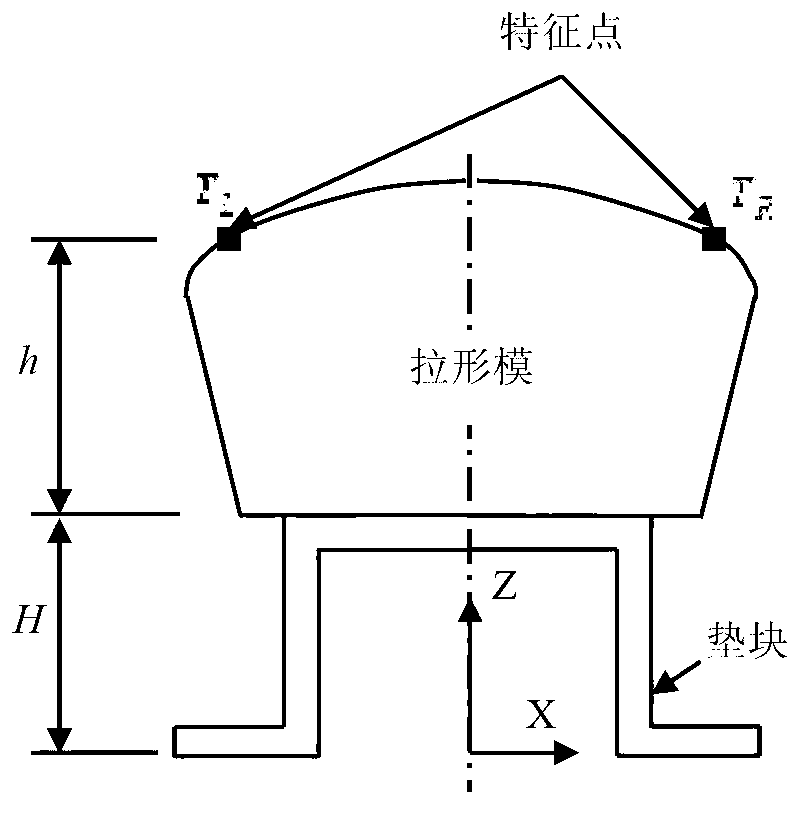

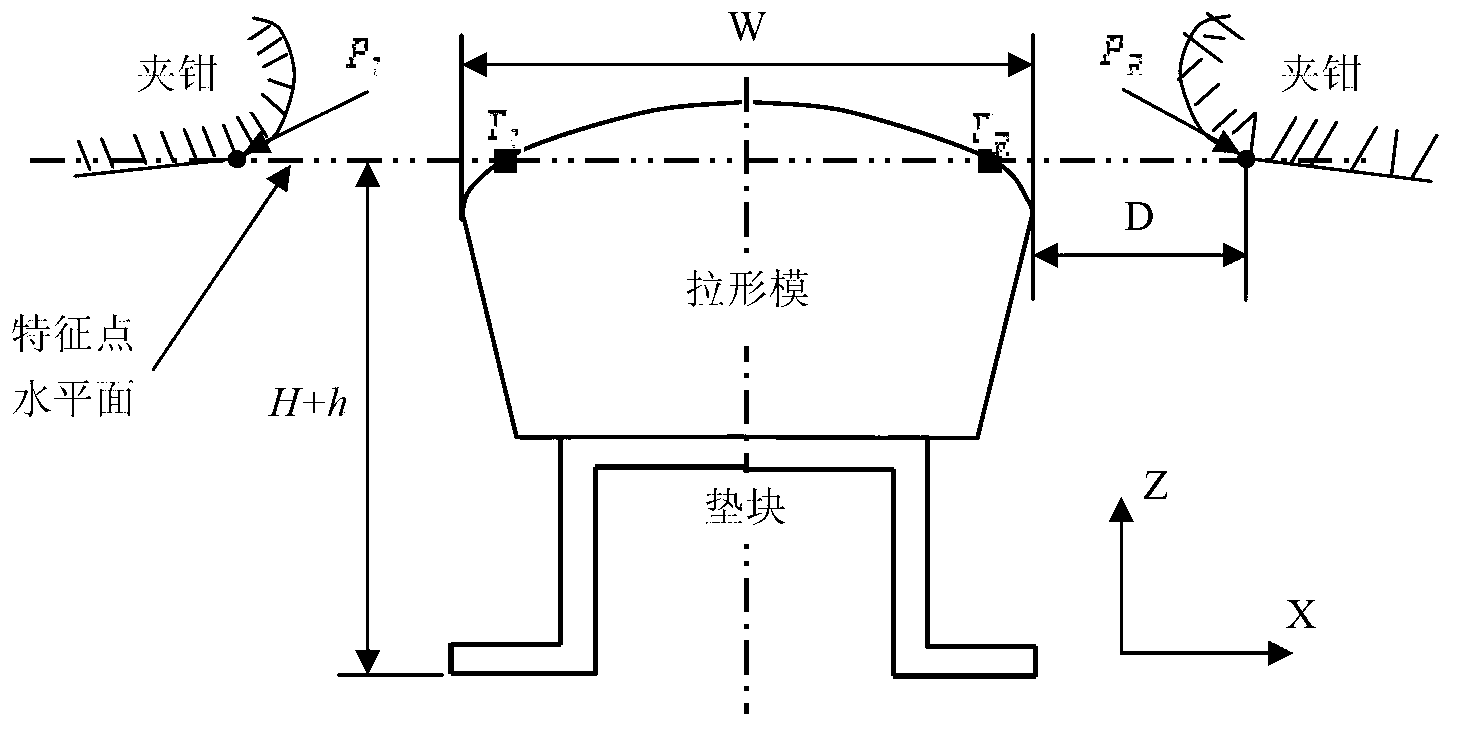

Mould positioning method based on feature distance

InactiveCN103302162BIncrease productivityIncrease error redundancyMetal-working feeding devicesPositioning devicesControl engineeringMotion parameter

The invention discloses a mould positioning method based on a feature distance. The method comprises the following five steps: 1, initially putting a mould, namely (1) putting a cushion block and (2) putting the mould; 2, moving equipment, namely (1) determining a coordinate, (2) reversing the equipment and (3) driving the equipment; 3, measuring and calculating, namely (1) measuring the distance and (2) geometrically calculating; 4, carrying out positioning calculation on the mould; and 5, correcting a digital control code for stretch forming. According to the method, the equipment is driven to move by motion parameters of a clamp position reversing stretch-forming machine according to equipment features of a ACB FET series digital control horizontal drawing machine, the coordinate and the space position of a mould feature point are calculated by the distance between a clamp feature point and the mould feature point, and the digital control code for the stretch forming is redesigned according to a mould position, thereby achieving accurate skin stretch forming; and due to a mould putting process in the method, the mould putting error redundancy can be increased, the mould putting time can be shortened, the use of a positioning tool can be reduced, and the production efficiency of aircraft skin stretch forming can be improved.

Owner:BEIHANG UNIV

Clip type skin stretching device

InactiveCN105455862AReduce the impactThe activity has little impactWound clampsSkin stretchEngineering

The invention provides a clip type skin stretching device. The device comprises a holder and an elastic hollow needle used to connect skin around a wound surface. The holder comprises a first supporting rod, a second supporting rod, a first rotating arm, and a second rotating arm. The first supporting rod and the second supporting rod are arranged at interval. The first supporting rod is provided with a rotary handle used to adjust the distance between the first supporting rod and the second supporting rod. One end of the first rotating arm and one end of the second rotating arm are respectively hinged with the first supporting rod. The other end of the first rotating arm and the other end of the second rotating arm are provided with fixation hooks used to connect with the elastic hollow needle. The second supporting rod is hinged with a first supporting arm which is arranged on the first rotating arm and a second supporting arm which is arranged on the second rotating arm. The device is small in operative wound, and simple and light in structure, and is suitable to be used for relatively regular skin defects, and reduce economical burdens of a patient.

Owner:常祺

Core formwork used for pouring top air passage of subway rail and construction method

ActiveCN110630019AEasy to removeReduced demolition workloadForms/shuttering/falseworksRear quarterWrinkle skin

The invention relates to a core formwork used for pouring a top air passage of a subway rail. The core formwork comprises a lower formwork plate, two side formwork plates separately hinged to the twoends of the upper side of the lower formwork plate, a supporting plate located over the lower formwork plate, and an inflatable airbag. Each side formwork plate comprises a side plate part hinged to the lower formwork plate and a corner part integrally formed on the upper edge of the side plate part, wherein one edge of the corner part is connected with the side plate part, and the other edge of the corner part upwards extends towards the supporting plate and abuts against the supporting plate. The inflatable airbag comprises an outer lining. The outer lining comprises slot-shaped first liningskin and second lining skin, wherein the first lining skin is fixed between the lower formwork plate and the two side formwork plates, and only the upper side of the first lining skin is opened; thesecond lining skin is fixed to the lower side of the supporting plate, and the two edges of the second lining skin stretch out of the supporting plate; and the edge of the second lining skin is fixedly connected with the open edge of the first lining skin, so that a wrinkle which is concave towards the interior of the outer lining is formed on the outer lining and corresponds to the contact position of the supporting plate and the lower formwork plate. The core formwork has the effects of being convenient to dismantle, small in dismantling work, and capable of saving time and labor.

Owner:CRPCEC SHENZHEN ENG

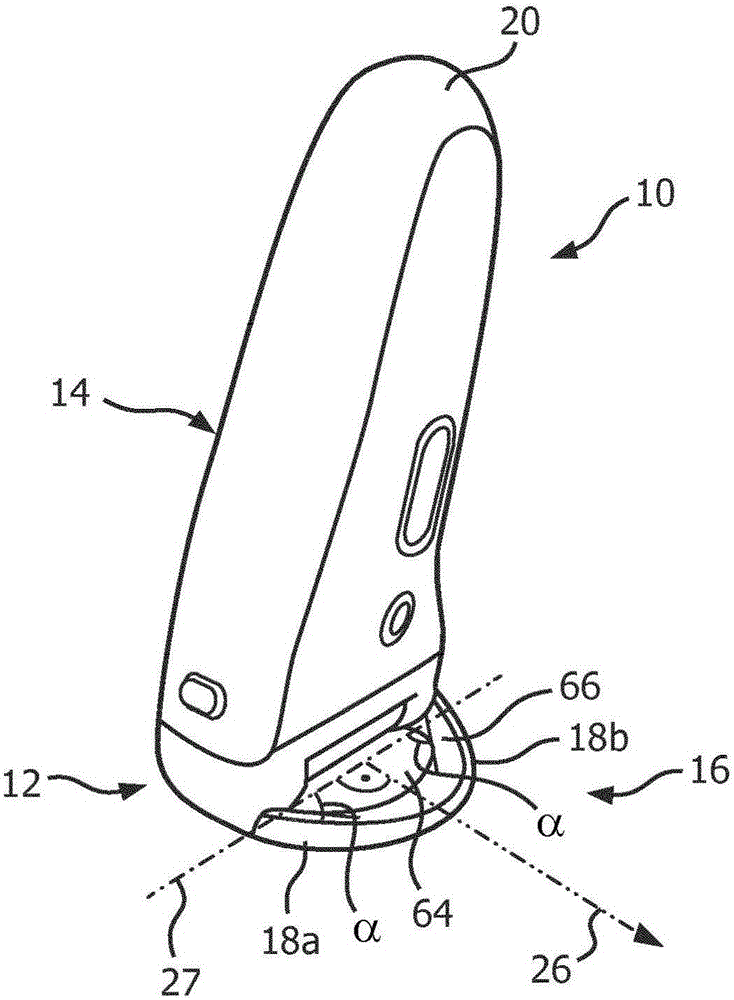

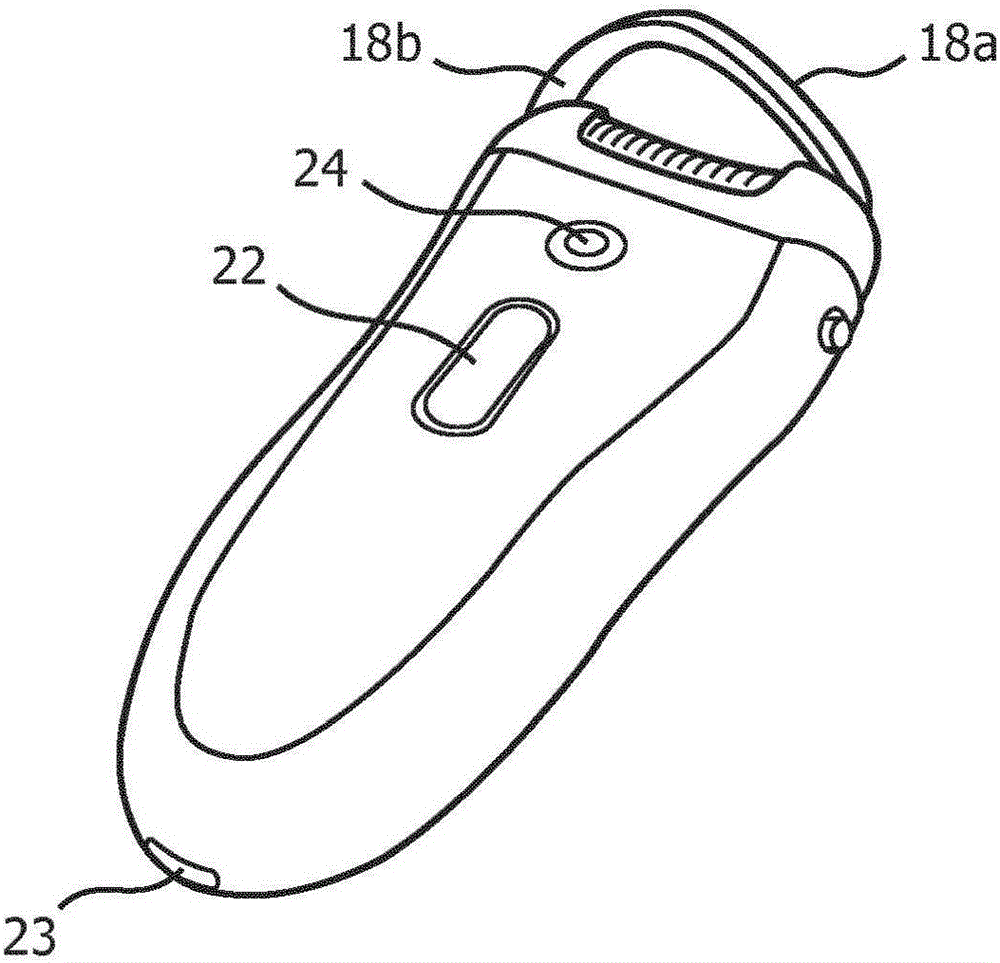

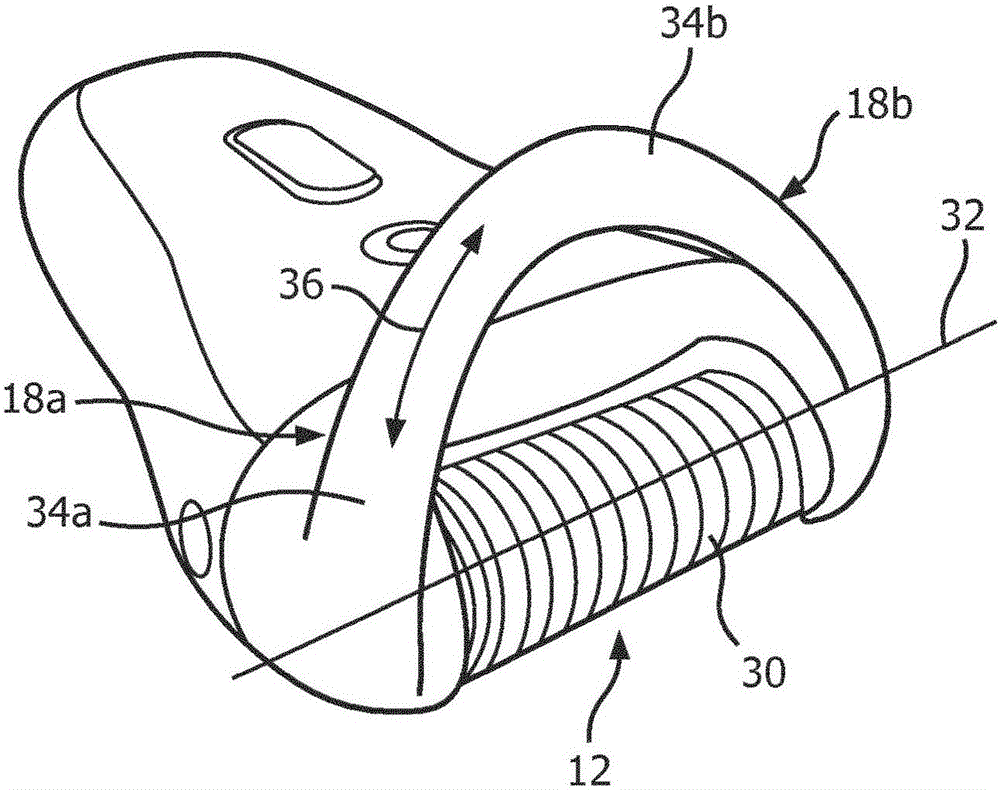

Hair removal apparatus

The present invention relates to hair removal, and in particular to a handheld hair removal apparatus. In order to reduce pain during hair removal, the handheld hair removal apparatus (10) comprises a hair removal arrangement (12), a support structure (14) and a skin stretching device (16) attached to the support structure and comprising at least two leading surface portions (18a, 18b) for skin contacting and stretching. The apparatus has a main movement direction (26) in which the apparatus is to be moved relative to skin during use. The hair removal arrangement comprises a skin contact portion (30) for contacting a user's skin during operation,wherein the skin contact portion extends at least along a primary axis (32) extending perpendicularly to the main movement direction (26). The at least two leading surface portions,seen in an imaginary plane comprising a base line (27) and extending parallel to the main movement direction (26),are arranged at opposite inclinations of at least 20 DEG with respect to the base line (27), which extends perpendicularly to the main movement direction and parallel to the primary axis, and are each provided with a skin touching surface portion (34a, 34b) having a main direction of extension that is inclined a tan angle of at least 20 DEG with the base line seen in said imaginary plane. During operation, the leading surface portions are brought into contact with the skin to act on the skin with a pushing force(42) having a first vector (38), parallel to the skin's surface, in a first direction (Y) parallel to the main movement direction, and a second vector (40), parallel to the skin's surface, in a second direction (X) perpendicular to the main movement direction. In an operational position, the skin stretching device is arranged in front of the skin contact portion with respect to the main movement direction. During operation, the skin stretching device provides a stretched skin portion between the at least two leading surface portions.

Owner:KONINKLIJKE PHILIPS NV

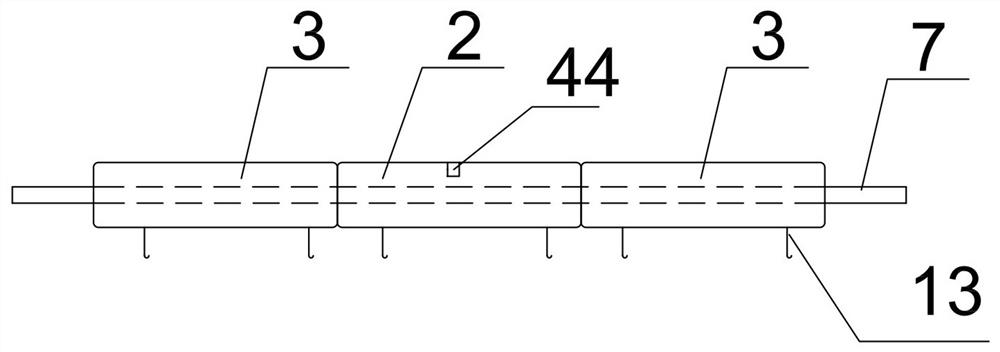

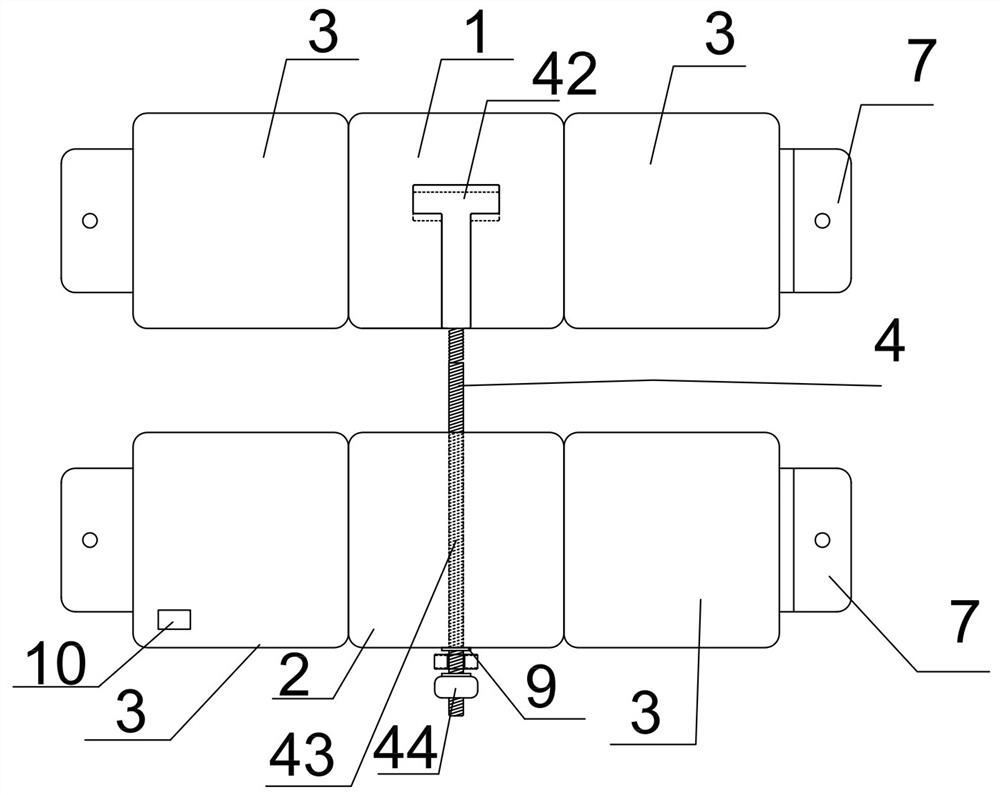

Intelligently-regulated skin stretching closer

PendingCN112535536AReduce necrosisPrevents tension differences from manual adjustmentsDiagnosticsSurgerySkin stretchingScars

The invention discloses an intelligently-regulated skin stretching closer. The intelligently-regulated skin stretching closer is characterized in that a stretching unit composed of a central stretching module A and stretching modules on the two sides and arranged on a connecting plate and another stretching unit composed of a central stretching module B and stretching modules on the two sides andarranged on the connecting plate are adopted, wherein the central stretching module A and the stretching modules on the two sides and the central stretching module B and stretching modules on the twosides are arranged on the connecting plates; and the two stretching units are connected through a T-shaped pull rod to form the H-shaped skin stretching closer. Compared with the prior art, the intelligently-regulated skin stretching closer has the advantages that no secondary trauma exists, scars are minimized, the epidermis healing effect is perfect, the stretching force is monitored in real time, the stretching force is accurately controlled to be at a stable safety level, the best stretching closing effect is achieved, complications such as skin necrosis are reduced, the situation that thestretching effect is affected due to the fact that the hard stretching force is too large or too loose is effectively prevented, and the intelligently-regulated skin stretching closer can adapt to different curved surface wounds during installation, is good in attaching protection performance and simple in structure and has wide application prospects in medical suturing.

Owner:周征兵 +1

Stretch forming technical method for high-temperature alloy materials

The invention belongs to the technical field of formation of high-temperature alloy materials, and relates to a stretch forming technical method for the high-temperature alloy materials. Compared with the prior art, the method uses a skin stretch forming technology, the forming defects of cracking, sliding lines, coarse grain, 'orange peel' and wrinkling existing on the surface of a part in the original forming process are avoided, and the quality of products is improved. In addition, as the skin stretch forming technology used by the method does not need heat treatment, the production efficiency is improved.

Owner:HARBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com