Large aircraft skin blank structure and skin stretching forming method

A technology of aircraft skin and blanks, which is applied to aircraft parts, fuselage bulkheads, transportation and packaging, etc., can solve the problems of uneven plastic deformation of the skin, unsatisfactory shape radian, and affect the acceptance of the skin, and achieve Optimize the structural form of the skin blank, improve the conformity of the shape arc, and the effect of excellent aircraft aerodynamic shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

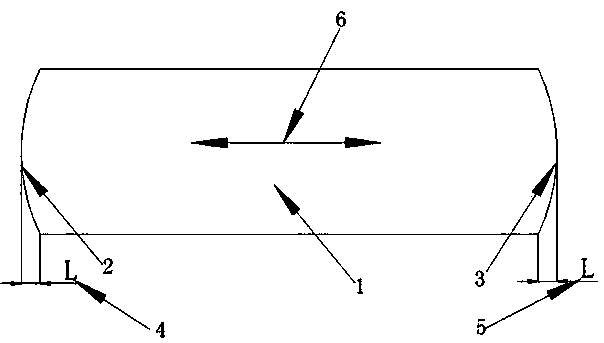

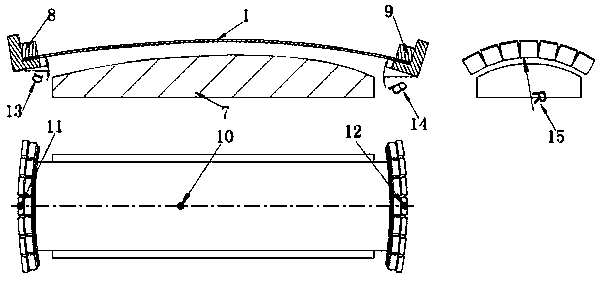

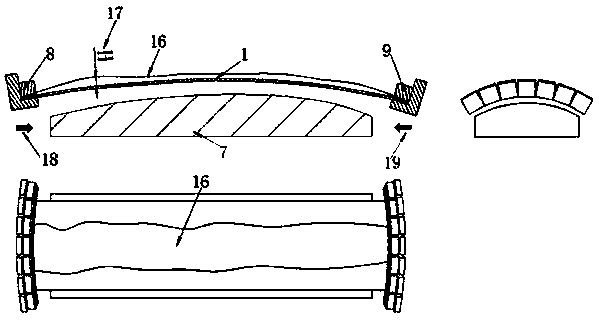

[0029] Attached below Figure 1-5 The present invention is further described in detail: a large-scale aircraft skin blank structure and a skin stretch forming method, wherein the technical equipment used for stretch forming at least includes a stretch machine jaw 9 and a skin stretch die 7, and the skin The end of the blank 1 in the stretching direction has a structure protruding outward in a circular arc.

[0030] Such as Figure 1-2 As shown, in order to adapt to the shape radian characteristics of different skin drawing dies 7, the skin blank 1 is designed so that one end or both ends in the stretching direction 6 have a structure that protrudes outward in an arc , to ensure that the skin blank 1 and the skin drawing die 7 have the best fit after stretching, the opposite ends of the skin blank 1 in this embodiment have a structure that protrudes to the outside: The arc protruding structure 2 at the end of the skin blank and the arc protruding structure 3 at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com