Method for producing visose fibre by non-zine solidification bathing

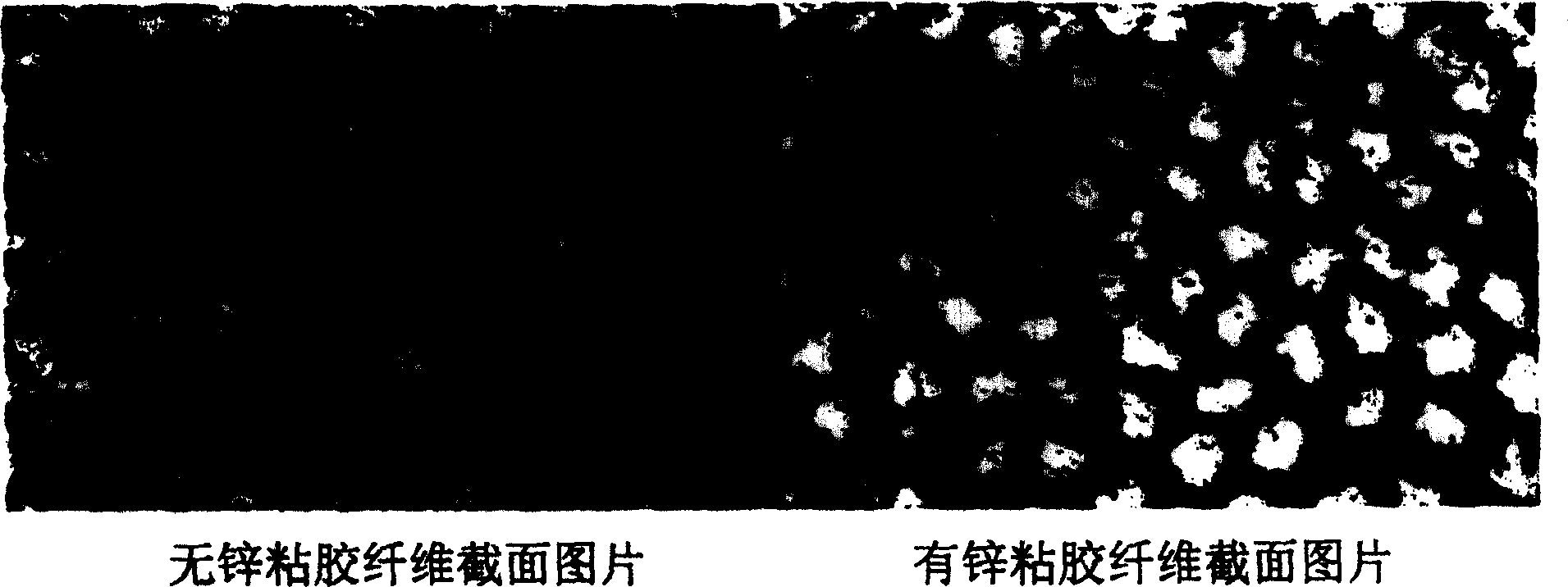

A viscose fiber and coagulation bath technology, applied in the field of man-made cellulose fiber production, can solve the problems that the content of coagulation bath components cannot be controlled, the effect of zinc ions cannot be achieved, and the human body is harmful, and the production process is easy to control, The fiber section is uniform and smooth, and the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add PEG-1600 with 2% A-cellulose content to the yellowed viscose, dissolve, mix and filter to obtain evenly mixed viscose, and ripen and defoam at room temperature for 8 hours at 17-18°C , to prepare spinning glue, methyl fiber: 8.6%, alkali content: 5.0%, viscosity: 40s, maturity: 16ml.

[0013] Coagulation bath: sulfuric acid 110-112g / l, sodium sulfate 240-250g / l, temperature 40-42°C, additive S653 content 1‰;

[0014] Spinning process: nozzle draft 56%, disc draft 23%, plastic draft 10%

[0015] Fiber index:

[0016] Dry breaking strength: 2.43cN / dtex

[0017] Wet breaking strength: 1.43cN / dtex

[0018] Dry elongation at break: 18.0%

[0019] Linear density deviation rate: -3.2%

[0020] Length deviation rate: -0.30%

[0021] Extra long fibers: 0%

[0022] Double-length fiber: 0mg / 100g

[0023] Residual sulfur content: 6.2mg / 100g

[0024] Defect: 0mg / 100g

[0025] Dry strength coefficient of variation (CV): 16.37%

[0026] Whiteness: 79%

[0027] Oil cont...

Embodiment 2

[0030] Add the melted AC1815 with 1% p-A cellulose content to the yellowed viscose, dissolve, mix and filter to obtain a uniformly mixed viscose, and ripen and defoam at a room temperature of 17-18°C8 Hours, the spinning glue was prepared, methyl fiber: 8.6%, alkali-containing: 5.0%, viscosity: 42s, maturity: 15ml.

[0031] Coagulation bath: sulfuric acid 110-112g / l, sodium sulfate 240-250g / l, temperature 40-42°C, additive S653 content 0.2‰, urea content 0.5‰;

[0032] Spinning process: nozzle draft 56%, disc draft 23%, plastic draft 10%;

[0033] Obtained viscose staple fiber index:

[0034] Dry breaking strength: 2.42cN / dtex

[0035] Wet breaking strength: 1.39cN / dtex

[0036] Dry elongation at break: 19.0%

[0037] Linear density deviation rate: -2.2%

[0038] Length deviation rate: -0.30%

[0039] Extra long fibers: 0%

[0040] Double-length fiber: 0mg / 100g

[0041] Residual sulfur content: 6.2mg / 100g

[0042] Defect: 0mg / 100g

[0043] Dry strength coefficient of...

Embodiment 3

[0048] Add melted AC1815 with 1.5% para-A cellulose content and 0.5% V315 to the yellowed viscose, dissolve, mix, and filter to obtain a uniformly mixed viscose at room temperature at 18~19°C After maturing and degassing for 15 hours, the spun gel was obtained, which had a fiber content of 8.2%, an alkali content of 5.8%, a viscosity of 38 s, and a maturity of 9.6 ml.

[0049] Coagulation bath: sulfuric acid 100~102g / l, sodium sulfate 240~250g / l, temperature 45~56℃, additive S653 content 1‰polyoxyethylene ether content 0.5‰.

[0050] Spinning process: nozzle draft -2.12%, disc draft 15.38%;

[0051] Obtained viscose filament index:

[0052] Dry breaking strength: 2.24cN / dtex

[0053] Wet breaking strength: 0.98cN / dtex

[0054] Dry elongation at break: 19.2%

[0055] Coefficient of variation (CV value) of dry elongation at break: 6.20%

[0056] Linear density (fineness) deviation: -4.0%

[0057] Linear density coefficient of variation (CV value): 3.0%

[0058] Twist vari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com