Fourdrinier section dewatering mechanism

A technology of machine wire section and net paper, which is applied in the field of dehydration mechanism of fourdrinier paper machine wire section, which can solve the problems of long dehydration line and difficult precise control of pulp turbulence, and achieve the effect of increasing output and improving dehydration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

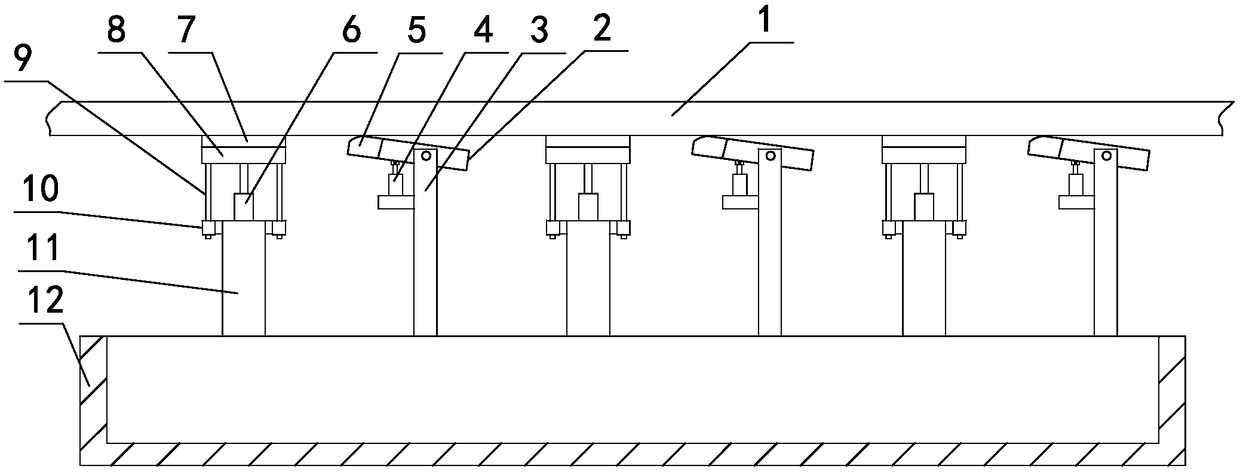

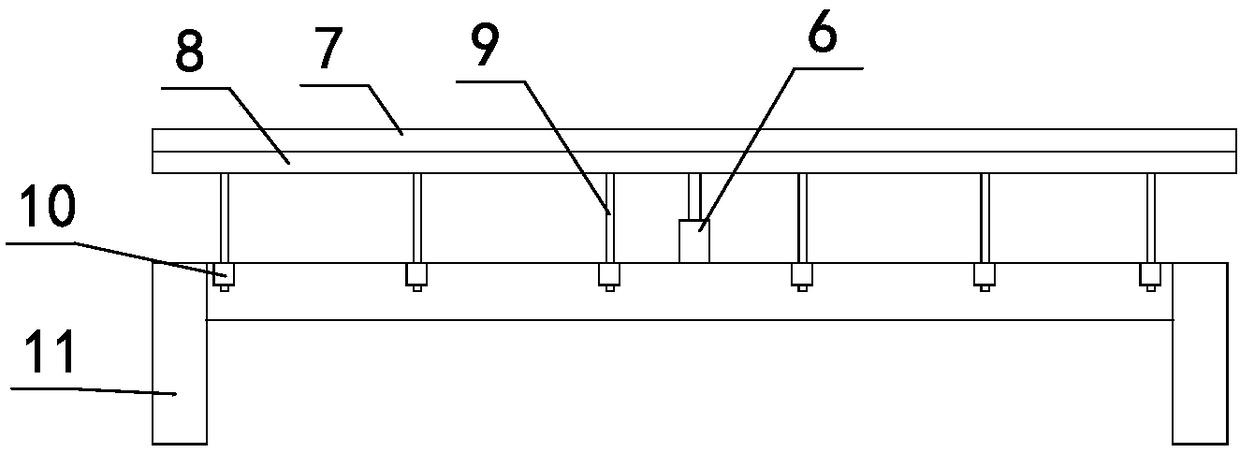

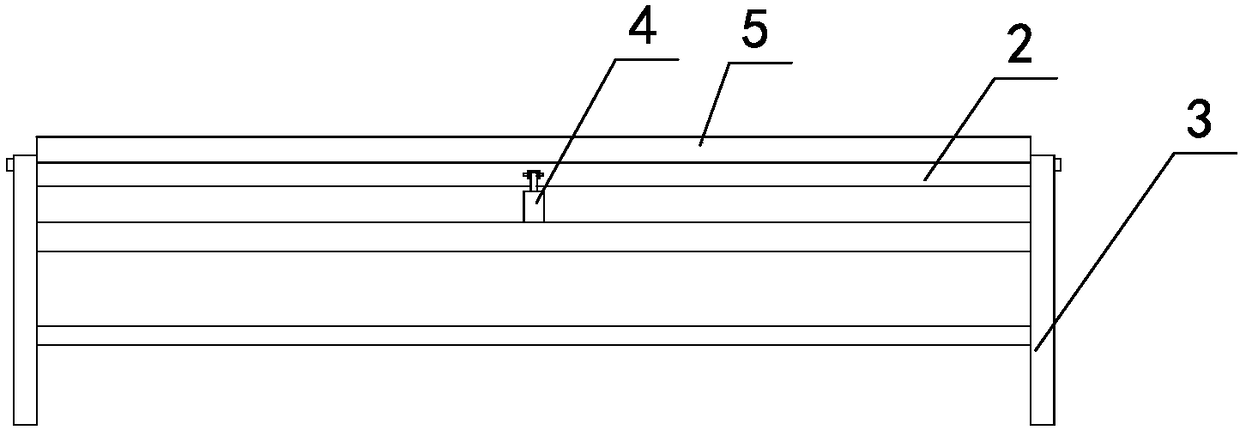

[0027] Such as figure 1 As shown, the dehydration mechanism of the fourdrinier paper machine wire section includes several groups of horizontally spaced brackets arranged horizontally, and each group of brackets includes a first bracket 3 and a second bracket 11 arranged horizontally spaced horizontally. The second bracket 11 is located at the first The left side of the bracket 3; the first bracket 3 is equipped with a rotating shaft arranged horizontally before and after, the first mounting plate 2 is installed on the rotating shaft, and corresponding to the first mounting plate 2 is provided with a handle for adjusting the rotation angle of the first mounting plate 2 Angle adjustment mechanism, a first wiper blade 5 for wiping is installed on the first mounting plate 2; a second mounting plate 8 is horizontally arranged on the front and back above the second bracket 11, and a second mounting plate 8 for wiping is installed on the second mounting plate 8. The second wiper bla...

Embodiment 2

[0039] Changes are made on the basis of Example 1, such as Figure 4 As shown, the angle adjustment mechanism and the lifting mechanism in Embodiment 1 are replaced, and the specific scheme is as follows:

[0040]Described angle adjusting mechanism comprises the rotating casing 13 that is vertically arranged on the left and right sides of first bracket 3, and threaded rod 14 is worn in the rotating casing 13, and the upper end of threaded rod 14 is hinged with first mounting plate 2, and threaded rod 14 and the rotating sleeve 13 are threaded, and the lower end of the rotating sleeve 13 is connected with a power mechanism for the rotating sleeve 13 to rotate positively and negatively; the power mechanism in this section of technology adopts a motor, and a servo motor and other motors can also be used. When in use, the rotating sleeve 13 is driven to rotate by using the positive and negative rotation of the motor. At this time, under the thread cooperation between the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com