A kind of integrated circuit board and preparation method thereof

A technology for integrated circuit boards and substrates, applied in printed circuit manufacturing, printed circuits, electrical components, etc., can solve problems affecting product yield, uneven distribution of resistance of electroplating layers, etc., to reduce losses, reduce contact resistance, improve The effect of forming uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

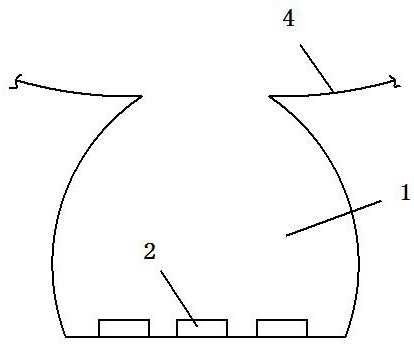

[0031] refer to figure 1 , a specific embodiment of the present invention comprises the following steps:

[0032] A. Perform pretreatment on the substrate, including cleaning and etching;

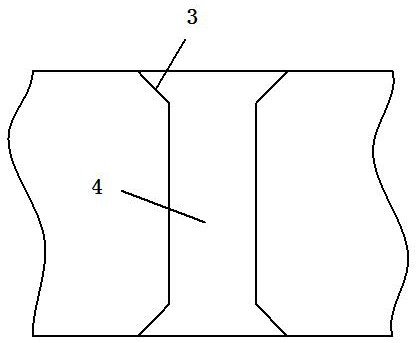

[0033] B. Perform positioning drilling on the substrate that has been pre-treated in step A, and make through holes 4;

[0034] C. Coating an isolation layer on the inner surface of the through hole 4, and then uniformly opening several grooves 1 along the axial direction on the inner surface of the through hole 4;

[0035] D. Carry out the first electroplating treatment to the groove 1 processed in step C;

[0036] E. Remove the remaining isolation layer on the inner surface of the through hole 4, and then perform a second electroplating treatment on the inner surface of the through hole 4;

[0037] F. Carry out secondary etching after cutting and laminating the substrate;

[0038] G. Coating a solder resist layer on the substrate, and then obtaining a finished integrated circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com