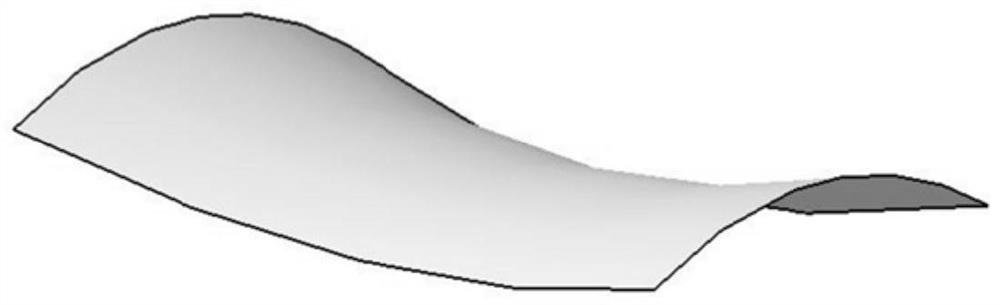

Forming method of saddle-shaped skin part

A technology of skin parts and saddle shape, which is applied in the application field of ribbed tooling, can solve the problems of rough grain, cracking, and inability to form blanks, and achieve the effects of reducing forming difficulty, increasing yield, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

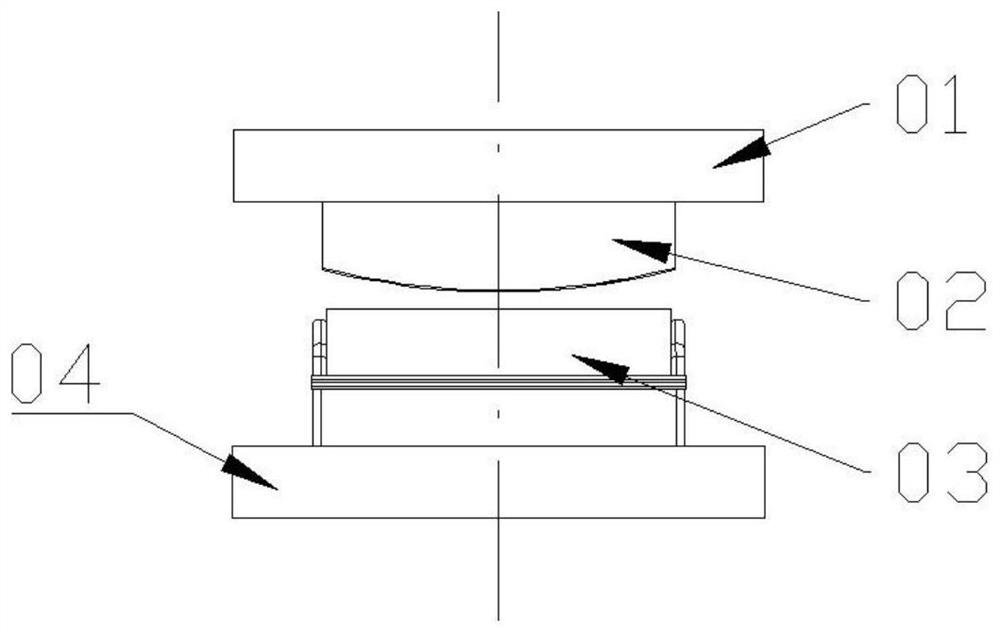

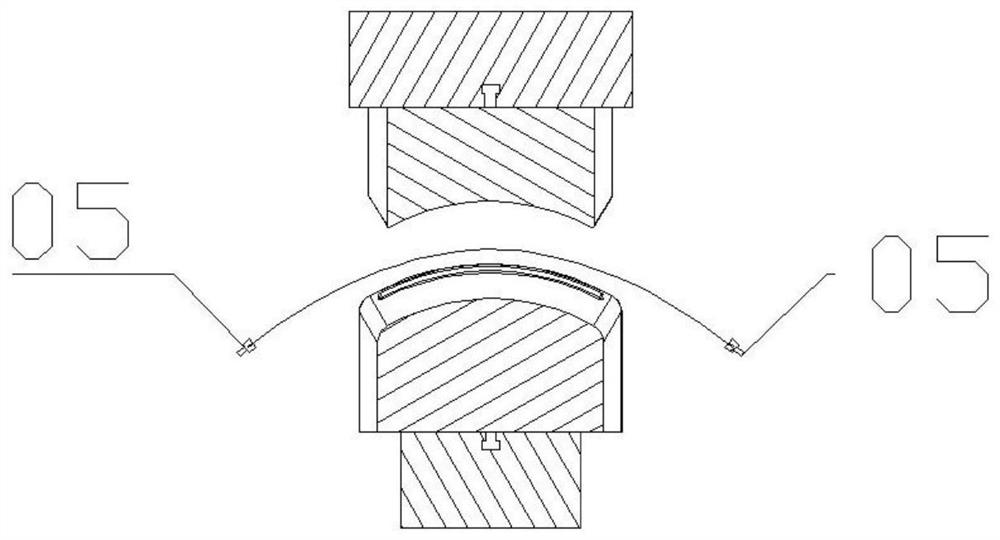

[0030] see Figure 1-Figure 4 , tooling for forming double-curvature aircraft skin parts, including the upper workbench 1 of the drawing equipment, the upper drawing die 2, the part sheet 3, the lower workbench 4 of the drawing equipment, the clamping jaw 5 of the drawing equipment, the drawing Die drawbead 6.

[0031] In this embodiment, the drawing die is made of material QT700 casting, its strength and wear resistance are more than 30% higher than that of ordinary steel, and the surface of the drawing die is ground to ensure that the roughness is not less than 1.6, reducing the sheet metal The friction between the drawing die and the drawing bead of the drawing die increases the transmission of the drawing force to facilitate the flow of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com