Mould quick replacing system of FET 1200 type skin stretching former

A technology of mold replacement and stretching machine, which is applied in the direction of forming tools, manufacturing tools, aircraft parts, etc., can solve problems such as difficulty in guaranteeing mold replacement and impact on the processing quality of skin parts, so as to reduce downtime waiting time, eliminate safety hazards, Avoid the effect of vehicle body imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

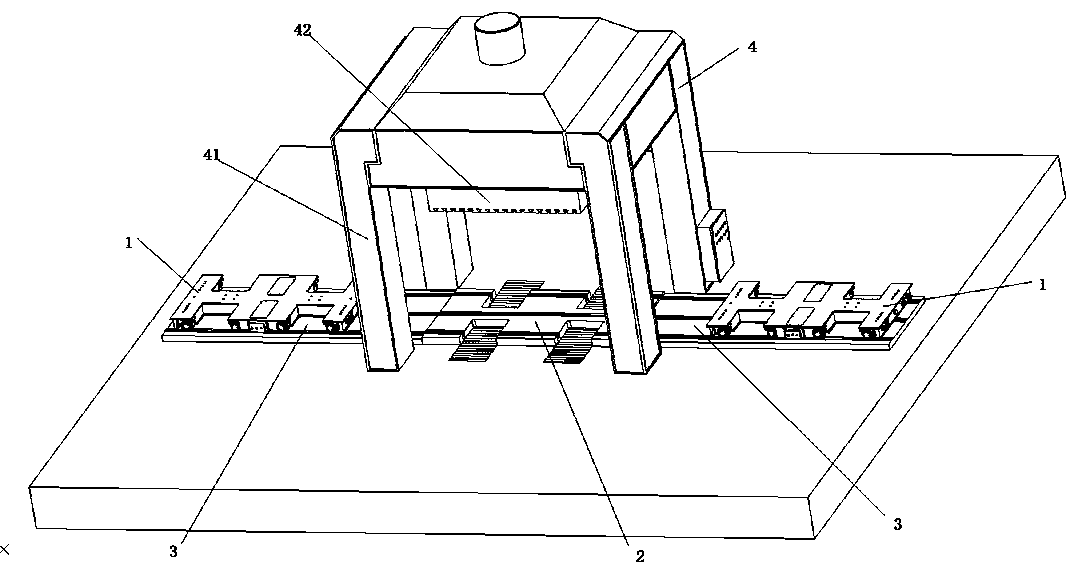

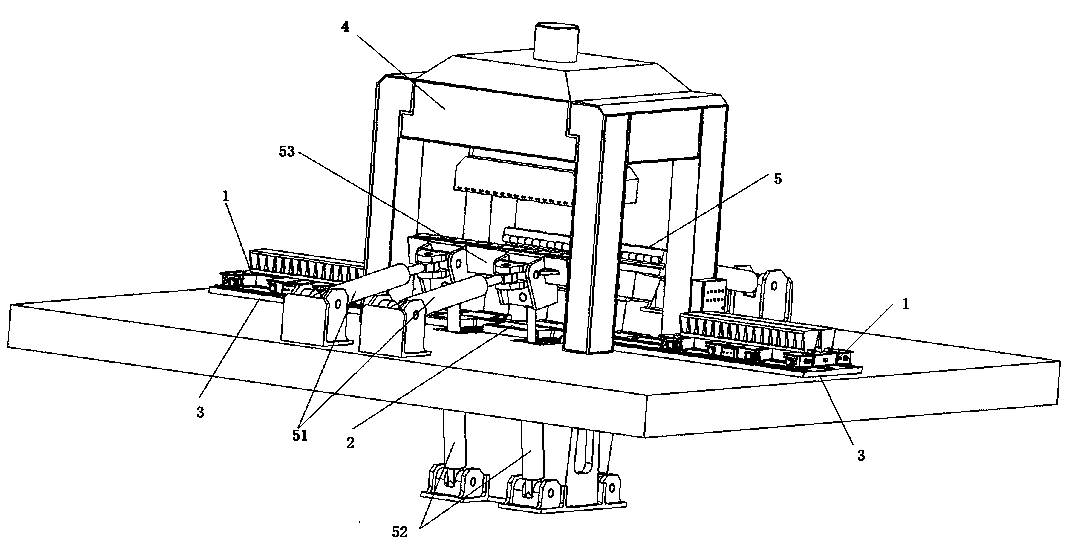

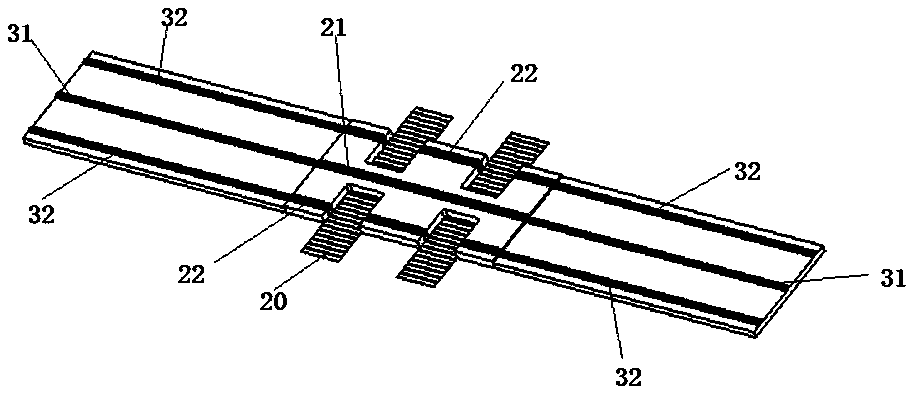

[0031] Such as Figure 5 As shown, the FET1200 skin stretching machine in the prior art mainly includes a frame, a pad 55, a mobile gantry device 54 and two sets of stretching devices 5, and the above two sets of stretching devices 5 are arranged on both sides of the pad, and Including hydraulic jaw 53, two horizontal oil cylinders 51 and two vertical oil cylinders 52. Two horizontal oil cylinders 51 are arranged on the top plane of the frame, one end of the cylinder barrel is hinged with the frame, and one end of its piston rod is hinged with the hydraulic jaw 53 . Two vertical oil cylinders 52 and horizontal oil cylinder 51 are approximately vertically arranged, and the piston rod of vertical oil cylinder 52 passes through frame, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com