Method for segmented stretch forming molding of 2000-series aluminum alloy skin

An aluminum alloy and skinning technology, which is applied in the field of aviation sheet metal parts forming, can solve the problems of independent adjustment, affecting the fluidity of the skin material, and insufficient plastic deformation, so as to prevent slip lines and cracks and excellent aircraft aerodynamics Shape, an effect that improves skin quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

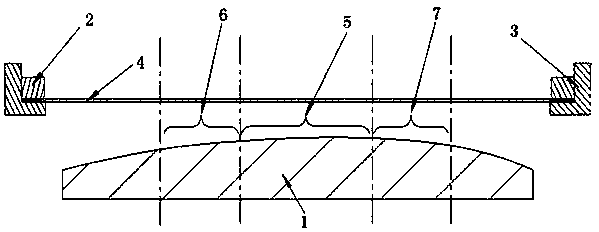

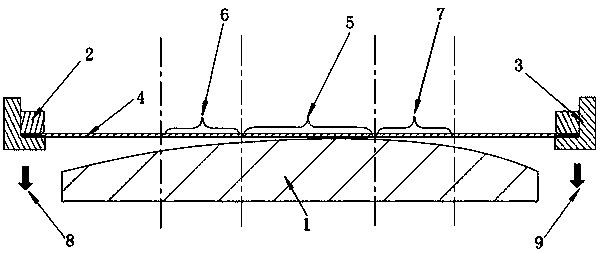

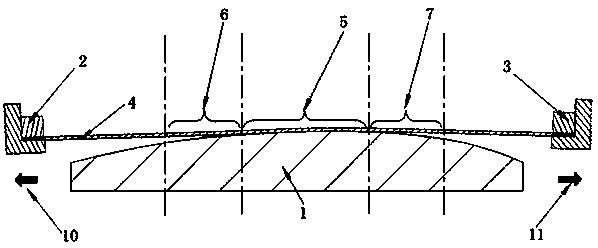

[0024] Attached below Figure 1-5 The present invention is further described in detail: a method for segmented stretch forming of a 2000 series aluminum alloy skin of a large aircraft. Similarly, the skin is stretched and formed in different steps. The stretching of each process makes the skin and the surface of the skin stretching die in a certain area completely fit. After the stretching of all processes is completed, the The surfaces of all regions of the skin and the skin stretching die are fully bonded, and the amount of tensile deformation in each process is the total deformation of the skin stretching / the number of the divided regions.

[0025] Specific steps are as follows:

[0026] Step 1: According to the shape surface size and radian characteristics of the skin drawing die 1, the shape surface of the skin drawing die 1 is divided into a plurality of drawing forming areas: the skin drawing die surface area one 5, the skin drawing Die surface area two 6, skin pullin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com