Core formwork used for pouring top air passage of subway rail and construction method

A technology of rail top air duct and construction method, which is applied in the direction of formwork/formwork/work frame, building, building structure, etc., which can solve the problems of inconvenient demolition for workers, and achieve the advantages of small demolition workload, improved service life and easy demolition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

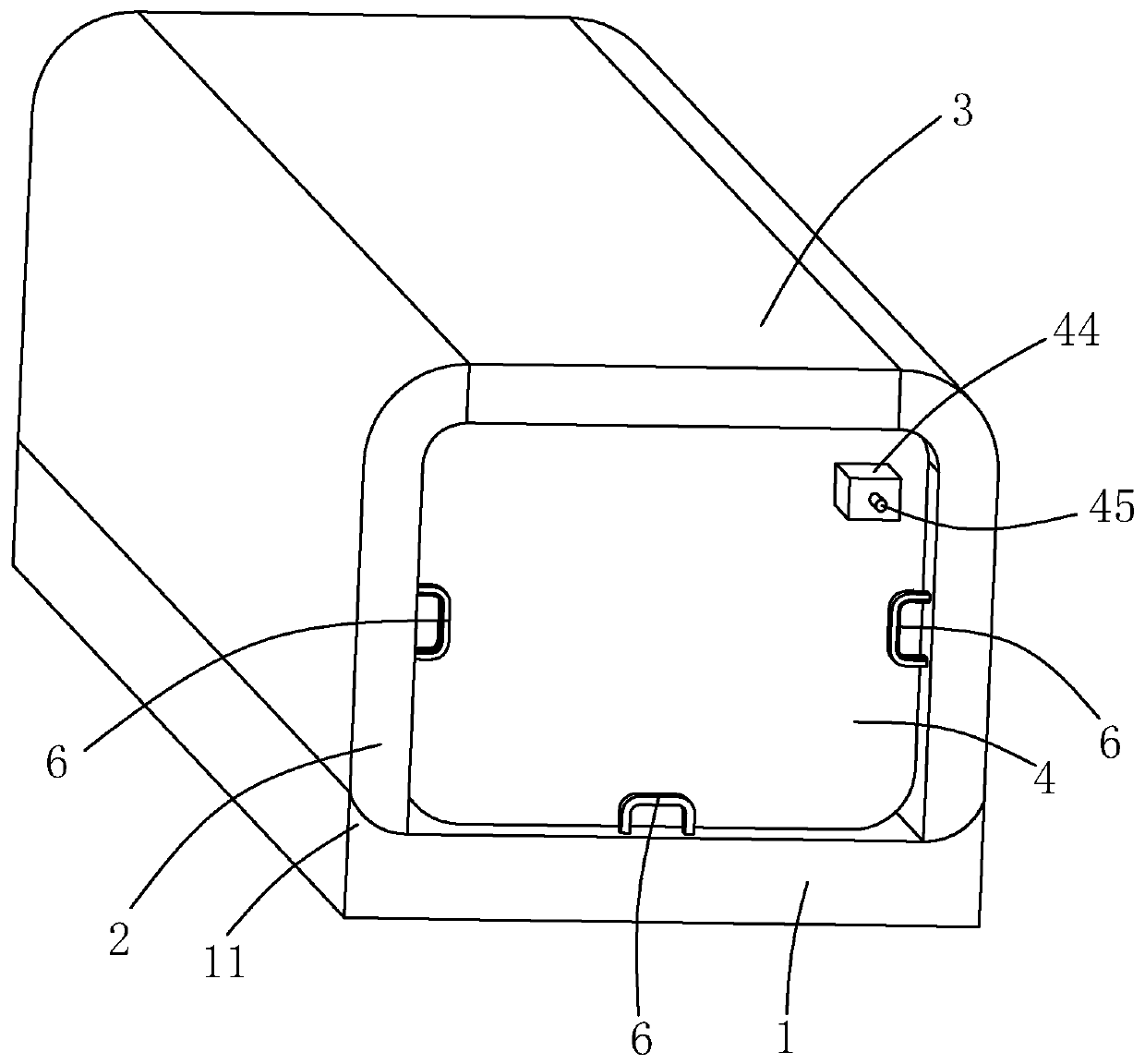

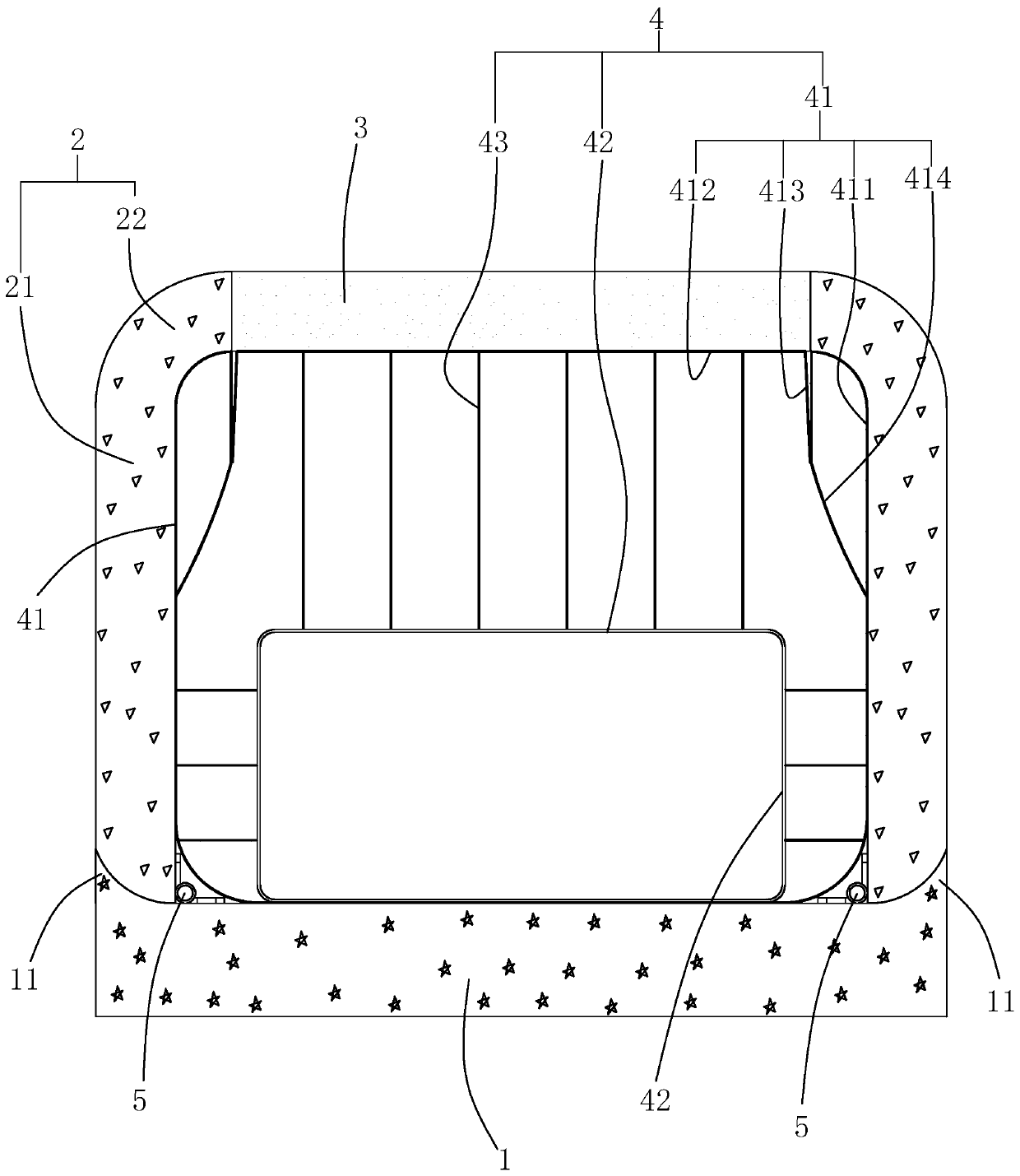

[0052] Reference figure 1 , Is a core mold for pouring a subway rail top air duct disclosed in the present invention, including a lower mold plate 1, two side mold plates hinged on both ends of the upper side of the lower mold plate 1, a supporting plate 3 located directly above the lower mold plate 1, and a The template 1, the two side templates 2 and the inflatable airbag 4 in the area enclosed by the support plate 3.

[0053] Reference figure 2 The side formwork 2 includes a side plate part 21 whose lower edge is hinged to the lower formwork 1 and a corner part 22 integrally formed on the upper edge of the side plate part 21. Specifically, the lower edge of the side plate 21 facing the inflatable airbag 4 is hinged with the lower template 1 through the hinge 5, and the side plate 21 is facing away from the inflatable airbag 4 so that the lower edge is processed with chamfered or rounded corners to Avoid scratching the rail top air duct when the side formwork 2 is separated fr...

Embodiment 2

[0060] This embodiment discloses a construction method for pouring a subway rail top air duct. The subway rail top air duct pouring uses a mandrel to perform part of the steps. The method includes the following steps:

[0061] Step 1. Set up steel pipe supports;

[0062] Step 2: Excavation of embedded steel bars;

[0063] Step 3. The integral steel reinforcement is installed to form a steel support and suspension structure for the air duct on the top of the rail;

[0064] Step 4. Mandrel installation, inflation and installation of external template of rail top air duct;

[0065] 4-1: Install the outer formwork on the underside and both sides of the rail top air duct;

[0066] 4-2: Insert the core mold into the steel supporting structure of the air duct on the top of the rail;

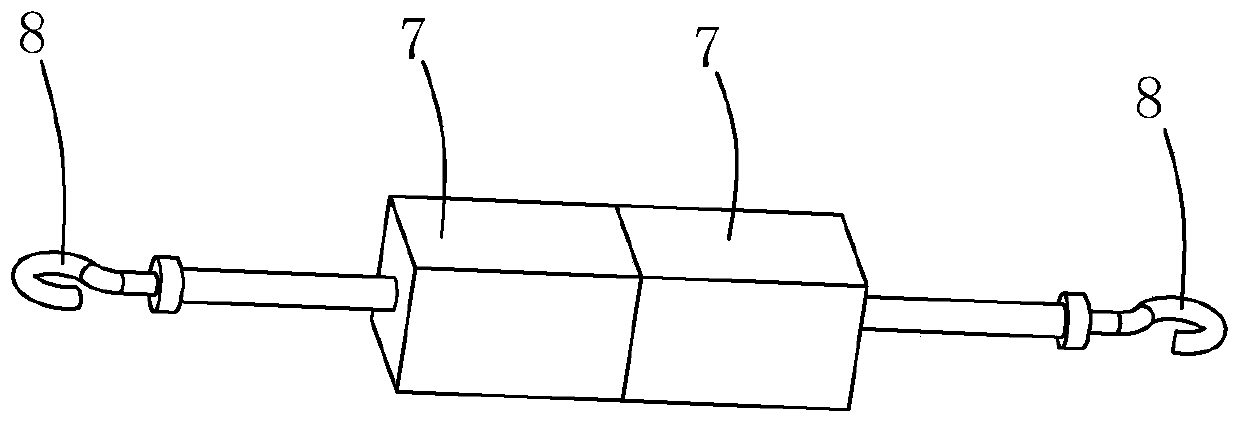

[0067] 4-3: Open the valve 44, connect the gas source to the gas nozzle 45 and inflate the gas into the inflatable airbag 4, and in the process of inflating the gas, manually adjust the position of the expenditure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com