Triazine charring agent, preparation method therefor and application thereof

A technology of triazines and char-forming agents, which is applied in the field of materials, can solve the problems of low thermal stability of products, large amount of organic solvents, and difficult follow-up treatment, etc., achieve good char-forming and flame-retardant effects, short reaction cycle, Good charcoal and flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take a 2L four-neck round-bottomed flask with a stirrer, thermometer, condenser and constant pressure dropping funnel, add 132g of hypophosphorous acid aqueous solution (50% content), 210.6g diethanolamine (99.7% content), and 1056g water into the flask , start stirring, add 17g of hydrochloric acid (content 31%), then raise the temperature to 95-100°C, add 170.3g of formaldehyde aqueous solution (content 37%) dropwise for 0.5-1h, continue the reaction for 3 hours after the addition, add 126g of melamine to continue the reaction After 2 hours, cool down, filter, and dry to obtain 412.1 g of charcoal agent, with a yield of 96.7% based on hypophosphorous acid.

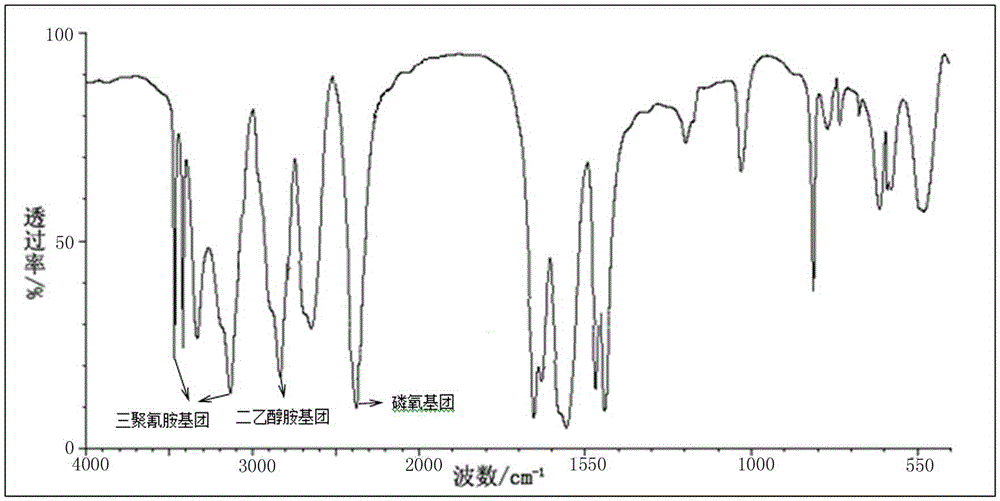

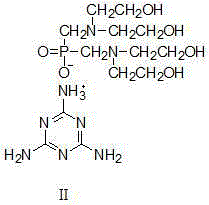

[0036] figure 1 It is the infrared spectrogram of the obtained char-forming agent. It can be seen from the figure that there are melamine groups, diethanolamine groups and phosphorus-oxygen groups, which are consistent with the structure of the new synthesized char-forming agent.

Embodiment 2

[0038] Take a 2L four-neck round bottom flask equipped with a stirrer, thermometer, condenser and constant pressure dropping funnel, add 132g of hypophosphorous acid aqueous solution (50% content), 210.6g of diethanolamine, and 1320g of water into the flask, and start stirring , add 17g of hydrochloric acid (content 31%), then raise the temperature to 95-100°C, add 170.3g of formaldehyde aqueous solution (content 37%) dropwise for 0.5-1h, continue the reaction for 3h after the dropwise addition, add 126g of melamine, continue the reaction for 2h, then cool down, Filtration and drying yielded 418.1 g of a novel char-forming agent, with a yield of 98.1% based on hypophosphorous acid.

Embodiment 3

[0040] Take a 2L four-neck round bottom flask equipped with a stirrer, thermometer, condenser and constant pressure dropping funnel, add 132g of hypophosphorous acid aqueous solution (50% content), 210.6g of diethanolamine, and 1584g of water into the flask, and start stirring , add 17g of hydrochloric acid (content 31%), then raise the temperature to 95-100°C, add 170.3g of formaldehyde aqueous solution (content 37%) dropwise for 0.5-1h, continue the reaction for 3h after the dropwise addition, add 126g of melamine, continue the reaction for 2h, then cool down, Filtration and drying yielded 417.9 g of a novel char-forming agent, with a yield of 98.1% based on hypophosphorous acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com