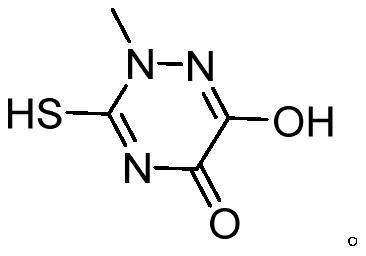

Preparation method of triazine ring

A technology of triazine ring and methyl thiosemicarbazide, applied in directions such as organic chemistry, can solve problems such as high cost, complicated process, inconvenient operation, etc., and achieve the effects of easy recovery and processing, cheap and easy-to-obtain raw materials, and avoiding difficulty in recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

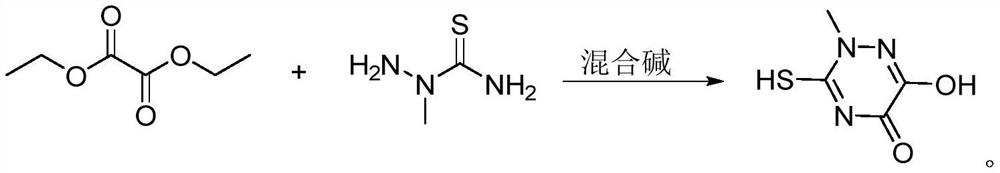

Method used

Image

Examples

Embodiment 1

[0036] Add 10.5 g of 2-methylthiosemicarbazide, 15.3 g of diethyl oxalate, 31.5 g of methanol, and 31.5 g of ethanol to the reaction flask, drop to 15° C., dropwise add a mixed alkali catalyst (including 36.8 g of sodium methoxide, 0.05 g of DMAP, TMEDA 0.05g) for 1.5h, after the dropwise addition, the temperature was raised to 55°C for cyclization reaction for 2.5h, acidified with hydrochloric acid to pH=1.0, cooled to 5°C and suction filtered to obtain a crude triazine ring. The crude product was dissolved in 63g of distilled water at 70°C and cooled down. Crystallization at 15°C, suction filtration to obtain a triazine ring wet product, and drying at 100°C for 3 hours to obtain 14.75 g of a triazine ring dry product with a purity of 99.6% and a yield of 92.7%.

Embodiment 2

[0038] Add 10.5 g of 2-methylthiosemicarbazide, 16.1 g of diethyl oxalate, 15.8 g of methanol, and 36.8 g of ethanol to the reaction flask, drop to 5°C, and dropwise add a mixed alkali catalyst (including 26.3 g of sodium methoxide, 0.01 g of DMAP, TMEDA 0.01g) 0.5h, the temperature was raised to 45°C for cyclization reaction for 4h after the dropwise addition, acidified with hydrochloric acid to pH=0.5, cooled to 0°C and suction filtered to obtain a crude triazine ring. The crude product was dissolved in 52.5g of distilled water at 65°C, and the temperature was lowered. Crystallization at 10°C, suction filtration to obtain a triazine ring wet product, and drying at 90°C for 5 hours to obtain 14.66 g of a triazine ring dry product with a purity of 99.7% and a yield of 92.1%.

Embodiment 3

[0040] Add 10.5 g of 2-methylthiosemicarbazide, 15.6 g of diethyl oxalate, 24 g of methanol, and 36 g of ethanol to the reaction flask, drop to 10°C, and dropwise add a mixed alkali catalyst (30 g of sodium methoxide, 0.02 g of DMAP, 0.03 g of TMEDA) ) 1h, the temperature was raised to 50°C for 3h after the dropwise addition, and the hydrochloric acid was acidified to pH=0.7, cooled to 3°C and suction filtered to obtain a crude triazine ring. The crude product was dissolved in 60 g of distilled water at 68°C, cooled to 13°C for crystallization , suction filtration to obtain the triazine ring wet product, which is dried at 95° C. for 4 hours to obtain 14.72 g of the triazine ring dry product with a purity of 99.6% and a yield of 92.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com