Silsesquioxane-modified melamine fire retardant and preparation method thereof

A technology of silsesquioxane and melamine, which is applied in the field of polymer materials and flame retardant chemistry, can solve the problems of complex preparation process of melamine flame retardant, influence of flame retardant performance, and inability to uniformly disperse, so as to achieve good development prospects and improve Good compatibility, mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

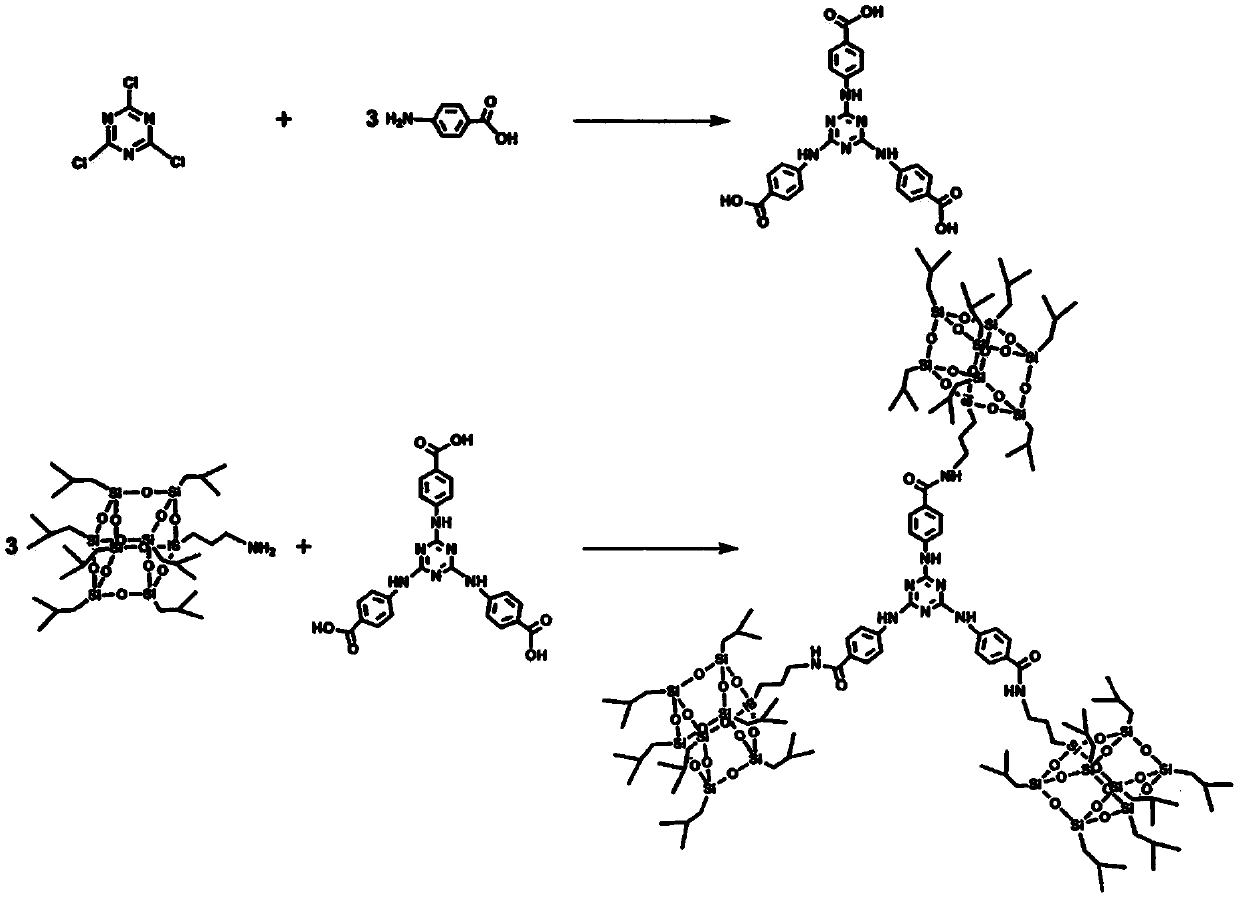

[0026] 1) Dissolve 1.3g of cyanuric chloride, 2.9g of p-aminobenzoic acid, and 1.4g of sodium hydroxide in 280mL of water, stir and react at 70°C for 24 hours, lower the reaction solution to room temperature, add concentrated hydrochloric acid to acidify, and filter the precipitate ,, 2.5 g of white powdery 4,4',4"-(1,3,5-triazine-2,4,6-triazine)tribenzoic acid was obtained after vacuum spin-drying.

[0027] 2) 2.3g of 4,4',4"-(1,3,5-triazine-2,4,6-triazol)tribenzoic acid and 4.7g of 2-ethoxy-1-ethoxy Carbonyl-1,2-dihydroquinoline was reacted at 65°C for 10 minutes in a mixed solvent of 640mL dioxane and 330mL methanol, then 12.4g of monoaminosilsesquioxane was added, and the reaction was continued for 24 hours Afterwards, it was lowered to room temperature, spin-dried in vacuo, and recrystallized twice with n-hexane to obtain 10.4 g of the target product.

Embodiment 2

[0029] 1) Dissolve 1.5g of cyanuric chloride, 3.3g of p-aminobenzoic acid, and 1.6g of sodium hydroxide in 320mL of water, stir and react at 80°C for 36 hours, lower the reaction solution to room temperature, add concentrated hydrochloric acid to acidify, and filter the precipitate , 2.8 g of white powdery 4,4',4"-(1,3,5-triazine-2,4,6-triazine)tribenzoic acid was obtained after vacuum spin-drying.

[0030] 2) 2.4g of 4,4',4"-(1,3,5-triazine-2,4,6-triazol)tribenzoic acid and 4.9g of 2-ethoxy-1-ethoxy Carbonyl-1,2-dihydroquinoline was reacted at 75°C for 20 minutes in a mixed solvent of 670mL dioxane and 340mL methanol, then 12.9g of monoaminosilsesquioxane was added, and the reaction was continued for 36 hours Afterwards, it was lowered to room temperature, spin-dried in vacuum, and recrystallized twice with n-hexane to obtain 10.9 g of the target product.

Embodiment 3

[0032] 1) Dissolve 1.8g of cyanuric chloride, 4.0g of p-aminobenzoic acid, and 2.0g of sodium hydroxide in 390mL of water, stir and react at 90°C for 48 hours, lower the reaction solution to room temperature, add concentrated hydrochloric acid to acidify, and filter the precipitate ,, 4.7 g of white powdery 4,4',4"-(1,3,5-triazine-2,4,6-triazine)tribenzoic acid was obtained after vacuum spin-drying.

[0033]2) 3.2g of 4,4',4"-(1,3,5-triazine-2,4,6-triazol)tribenzoic acid and 6.5g of 2-ethoxy-1-ethoxy Carbonyl-1,2-dihydroquinoline was reacted at 85°C for 30 minutes in a mixed solvent of 890mL dioxane and 460mL methanol, then 17.2g of monoaminosilsesquioxane was added, and the reaction was continued for 48 hours Afterwards, it was lowered to room temperature, spin-dried in vacuum, and recrystallized twice with n-hexane to obtain 14.5 g of the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com