Binding agent, application of binding agent, composite product, and preparation method and application of composite product

A technology of composite products and binders, applied in chemical instruments and methods, binder additives, non-polymer binder additives, etc., which can solve problems such as differences in adhesion and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

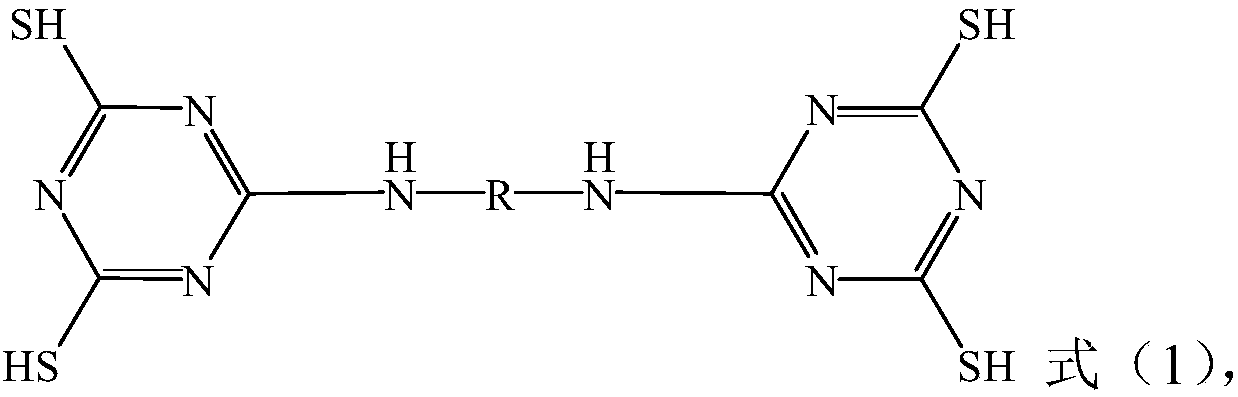

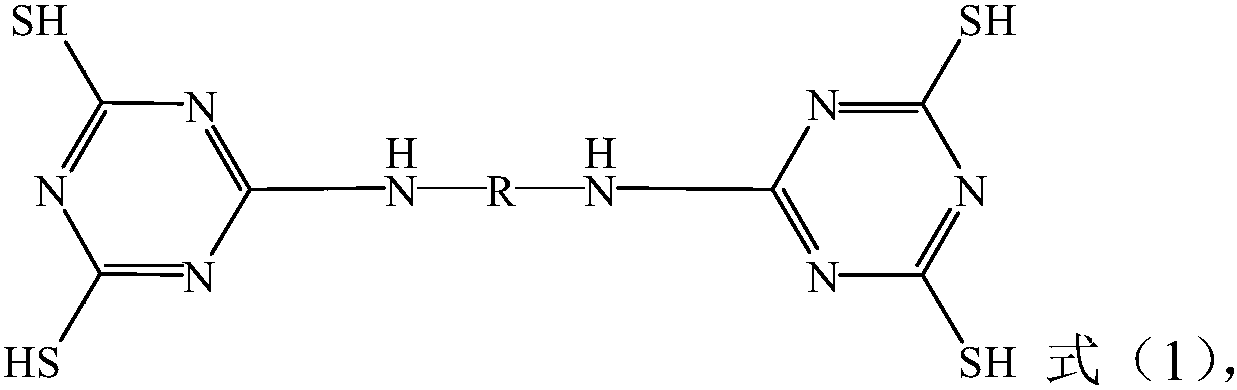

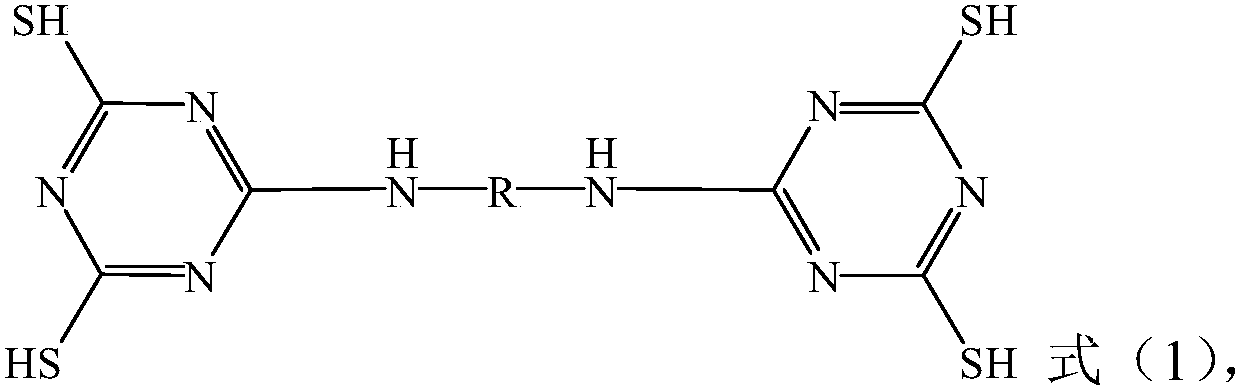

[0020] According to a preferred embodiment of the present invention, the bistriazine thiol compound is prepared according to the following method:

[0021] (1) cyanuric chloride and general formula are NH 2 -R-NH 2 The diamine-based compound is subjected to the first reaction at 0-15°C;

[0022] (2) After the first reaction product is mixed with sodium sulfide and hydrochloric acid, the second reaction is carried out at 0-10° C. and the third reaction is carried out under reflux conditions.

[0023] Concrete reaction process is as follows:

[0024]

[0025] The present invention does not specifically limit the reaction time of each stage in the preparation process of the bistriazine thiol compound. The time for the first reaction is preferably 1-5 hours, more preferably 2-4 hours. The time for the second reaction is preferably 1-3 hours, more preferably 1-2 hours. The time for the third reaction is preferably 2-6 hours, more preferably 3-5 hours.

[0026] According to...

specific Embodiment approach

[0031] According to a specific embodiment of the present invention, the bis-triazine thiol compound is prepared according to the following method:

[0032] (1) In a dry round bottom flask, dissolve cyanuric chloride in an organic solvent (the mass ratio of organic solvent to cyanuric chloride is 8-12:1, preferably 9-11:1), then cool to 0-5°C, preferably cooling to 0-3°C, to obtain a cyanuric chloride solution. Diamine-based compound (the molar ratio of cyanuric chloride to diamine-based compound is 1-5:1, preferably 2-3:1, more preferably 2.2-2.8:1) is slowly added to the above-mentioned cyanuric chloride In the solution, then react at low temperature (0-15°C, preferably 5-13°C) for 1-5h, preferably 2-4h, to form an intermediate, and the by-product is HCl;

[0033] (2) sodium sulfide (Na 2 The mol ratio of S to cyanuric chloride is 1-5:1, preferably 2-4:1, more preferably 2.2-3:1) dissolved in water, slowly add hydrochloric acid aqueous solution (the hydrochloric acid aqueou...

preparation example 1

[0051] This preparation example is used to illustrate the preparation method of the bis-triazine thiol compound having the structure represented by formula (1) provided by the present invention.

[0052] (1) In a dry round bottom flask, dissolve 55.35g (0.3mol) of cyanuric chloride with 498.15g of acetone (the mass ratio of acetone to cyanuric chloride is 9:1), cool to 0°C to obtain three polychloride solution. Slowly add 8.18g (0.136mol) of ethylenediamine (the molar ratio of cyanuric chloride to ethylenediamine is 2.2:1) into the above cyanuric chloride solution, and react at 5°C for 4h to form intermediate A1, The by-product is HCl.

[0053] (2) 51.48g (0.66mol) of Na 2 S(Na 2 The molar ratio of S to cyanuric chloride is 2.2:1) dissolved in water, slowly add 264ml of 2mol / L hydrochloric acid aqueous solution (HCl and Na 2 The molar ratio of S is 0.8:1), then intermediate A1 was added, reacted at 0°C for 2h, and then heated to reflux for 3h. The reaction product was was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com