Continuous production method of multi-kettle serial triazine herbicide

A technology of multi-reactor series connection and production method, applied in the direction of organic chemistry, can solve the problems of low cost performance, slow reaction titration speed, low load of a single set, etc., achieve high degree of process automation, strong continuity of production process, good The effect of social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

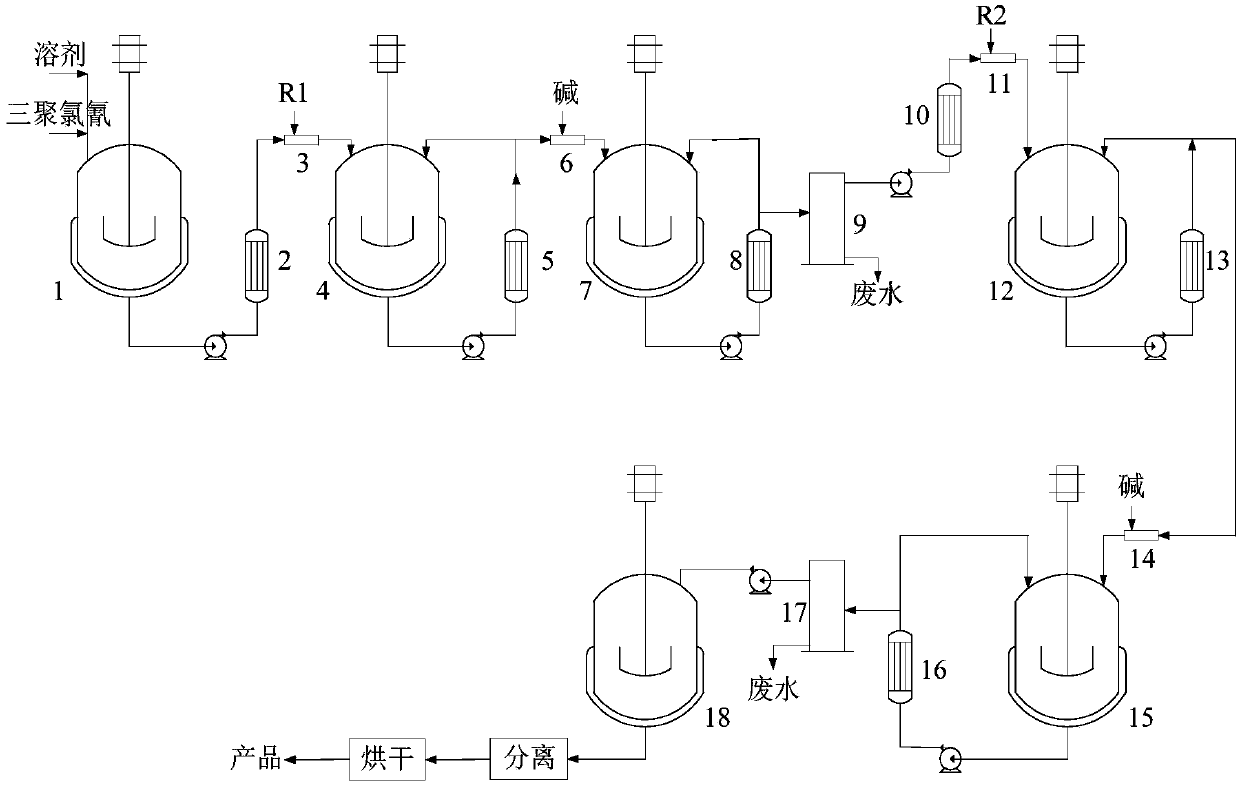

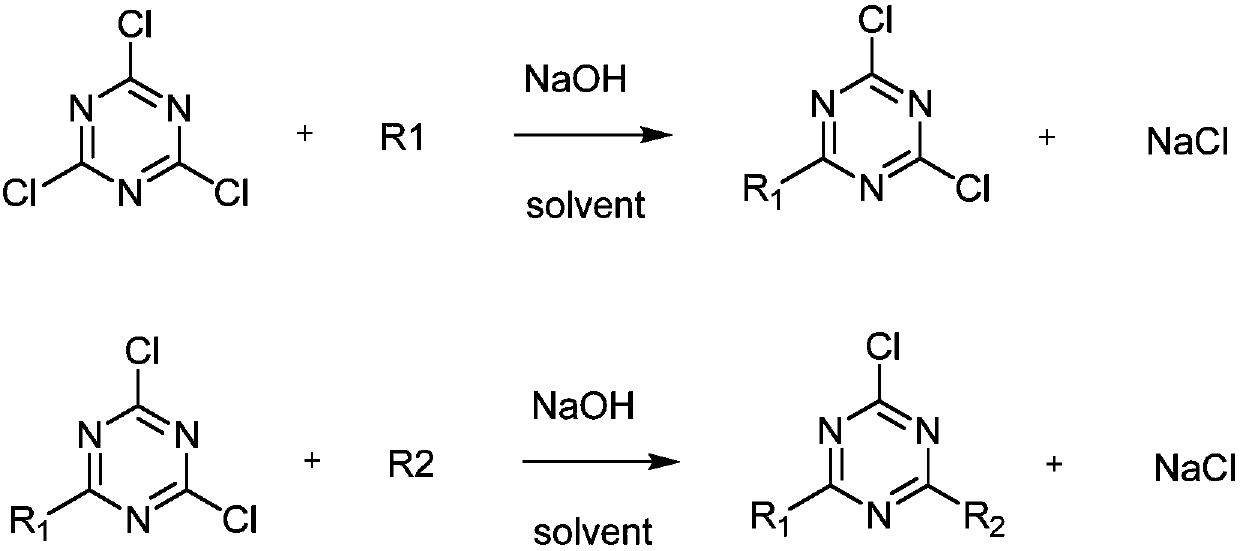

[0090] Embodiment 1: The multi-pot continuous production method of atrazine

[0091] (1) Charge a certain amount of nitrogen in the batching kettle 1 for replacement, cyanuric chloride and toluene are added to the batching kettle in a ratio of 1:5 by mass ratio, fully dissolved to obtain a toluene solution of cyanuric chloride;

[0092] (2) the above-mentioned prepared cyanuric chloride solution passes through precooler 2 according to the flow rate of 6000kg / hour (wherein cyanuric chloride 1000kg / hour), and the material outlet temperature of control precooler 2 is at 5-7 ℃, and The precisely metered 70% aqueous solution of isopropylamine is fully mixed in the mixer 3 and enters a reactor 4, and the flow rate of the aqueous solution of isopropylamine is controlled at 460kg / hour.

[0093] (3) One-stage reactor 4 (reactor volume 5m 3 ) The reaction solution enters the heat exchanger 5 through the pump (the material outlet temperature is controlled at 13-15°C) for extracorporeal ...

Embodiment 2

[0100] Embodiment 2: the multi-reactor series continuous production method of simazine

[0101] (1) Charge a certain amount of nitrogen in the batching kettle 1 for replacement, cyanuric chloride and toluene are added to the batching kettle in a ratio of 1:5 by mass ratio, fully dissolved to obtain a toluene solution of cyanuric chloride;

[0102] (2) the above-mentioned prepared cyanuric chloride solution passes through precooler 2 according to the flow rate of 6000kg / hour (wherein cyanuric chloride 1000kg / hour), and the material outlet temperature of control precooler 2 is at 5-7 ℃, and The precisely metered 70% aqueous solution of isopropylamine is fully mixed in the mixer 3 and enters a reactor 4, and the flow rate of the aqueous solution of monoethylamine is controlled at 350 kg / hour.

[0103] (3) One-stage reactor 4 (reactor volume 5m 3 ) The reaction solution enters the heat exchanger 5 through the pump (the material outlet temperature is controlled at 8-10°C) for extr...

Embodiment 3

[0110] Embodiment 3: the continuous production method of terbutyline in series with multiple reactors

[0111] (1) Charge a certain amount of nitrogen in the batching kettle 1 for replacement, cyanuric chloride and toluene are added to the batching kettle in a ratio of 1:5 by mass ratio, fully dissolved to obtain a toluene solution of cyanuric chloride;

[0112] (2) the above-mentioned prepared cyanuric chloride solution passes through precooler 2 according to the flow rate of 6000kg / hour (wherein cyanuric chloride 1000kg / hour), and the material outlet temperature of control precooler 2 is at 5-7 ℃, and The precisely metered 70% aqueous solution of tert-butylamine is fully mixed in the mixer 3 and enters the first-stage reactor 4, and the flow rate of the aqueous solution of tert-butylamine is controlled at 566.5 kg / hour.

[0113] (3) One-stage reactor 4 (reactor volume 5m 3 ) The reaction liquid enters the heat exchanger 5 through the pump (the material outlet temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com