Preparation method of homopolymerized organosilicon resin microspheres

A technology of resin microspheres and polyorganosilicon, which is applied in the chemical industry, can solve the problems of wide particle size distribution and limited application, and achieve the effect of strong production process continuity, narrow particle size distribution and particle size reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

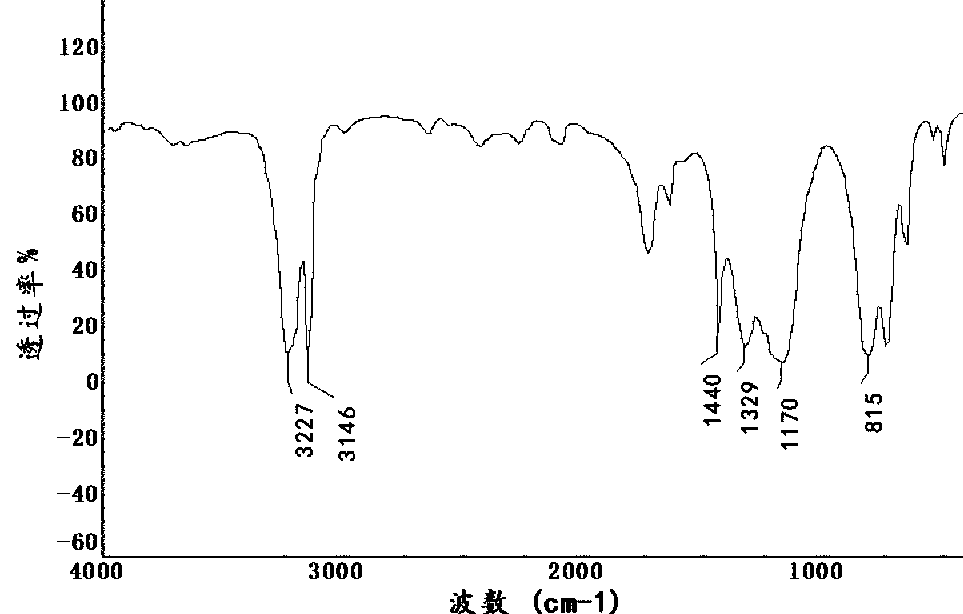

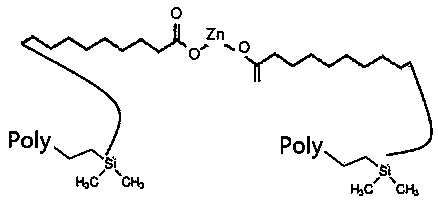

Image

Examples

Embodiment 1

[0023] A preparation method of homopolymeric silicone resin microspheres, the operation steps are:

[0024] Put 80g of methyltrimethoxysilane and 350g of deionized water into the reactor, add hydrochloric acid with a mass percentage concentration of 10 to adjust the pH value to 3, stir evenly, heat up to 40°C, and keep it warm for 60min for hydrolysis reaction; then add 0.1g of Metal silane particle size control agent, after stirring and mixing evenly, add 0.3g of 8% NaOH solution, adjust the pH value to 8, and carry out polycondensation reaction; after heat preservation polycondensation reaction for 60 minutes, add 5%-dilute sulfuric acid to adjust the pH value to neutral, and discharge , dehydration; then washing the slurry, drying at 100° C., and crushing to obtain the homopolymeric silicone resin microspheres.

[0025] Described metallocene silane particle size control agent is processed according to the following methods:

[0026] Get 3g of 2-methyl-2-[(1-oxo-2-propenyl)...

Embodiment 2

[0032] A preparation method of homopolymeric silicone resin microspheres, the operation steps are:

[0033] Put 90g of methyltrimethoxysilane and 50g of deionized water into the reactor, add hydrochloric acid with a mass percentage concentration of 14 to adjust the pH value to 5, stir evenly, heat up to 60°C, and keep it warm for 80min for hydrolysis reaction; then add 0.5g of Metal silane particle size control agent, after stirring and mixing evenly, add 0.5g of 10% NaOH solution, adjust the pH value to 9, and carry out polycondensation reaction; after heat preservation polycondensation reaction for 90min, add 8% dilute sulfuric acid to adjust the pH value to neutral, discharge, Dehydration; then washing the slurry, drying at 110°C, and crushing to obtain the homopolymeric silicone resin microspheres.

[0034] Described metallocene silane particle size control agent is processed according to the following methods:

[0035] Get 5g of 2-methyl-2-[(1-oxo-2-propenyl)amino]-1-pro...

Embodiment 3

[0043] A preparation method of homopolymeric silicone resin microspheres, the operation steps are:

[0044] Put 100g of methyltrimethoxysilane and 800g of deionized water into the reactor, add hydrochloric acid with a mass percentage concentration of 20 to adjust the pH value to 6, stir evenly, heat up to 80°C, and keep it warm for 90min for hydrolysis reaction; then add 1g of metallocene Silane particle size control agent, after stirring and mixing evenly, add 0.6g of 12% NaOH solution, adjust the pH value to 10, and carry out polycondensation reaction; after 120 minutes of heat preservation polycondensation reaction, add 10% dilute sulfuric acid to adjust the pH value to neutral, discharge, Dehydration; then washing the slurry, drying at 120°C, and crushing to obtain the homopolymeric silicone resin microspheres.

[0045] Described metallocene silane particle size control agent is processed according to the following methods:

[0046] Get 8g of 2-methyl-2-[(1-oxo-2-propenyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com