Triazinyl nitrogen-phosphorus flame retardant, preparation method and water-based acrylic coating

A technology of triazine-based nitrogen-phosphorus system and water-based acrylic acid, which is applied in the field of flame-retardant materials, can solve the problems of material performance degradation and affect the appearance of products, and achieve the effect of improving flame-retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

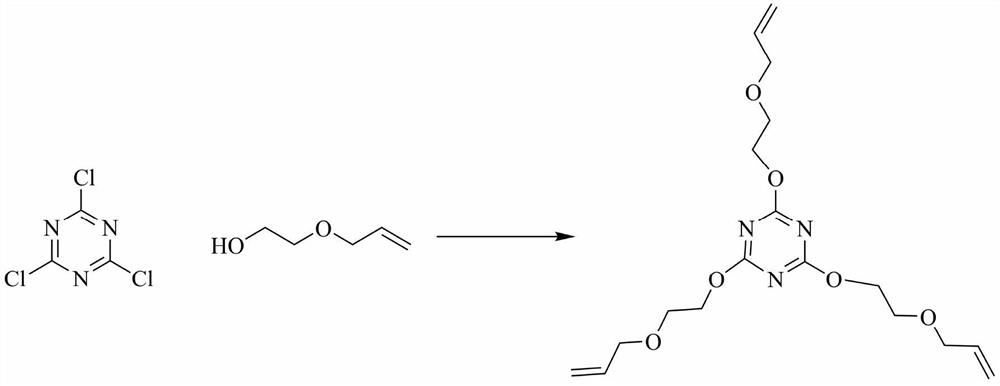

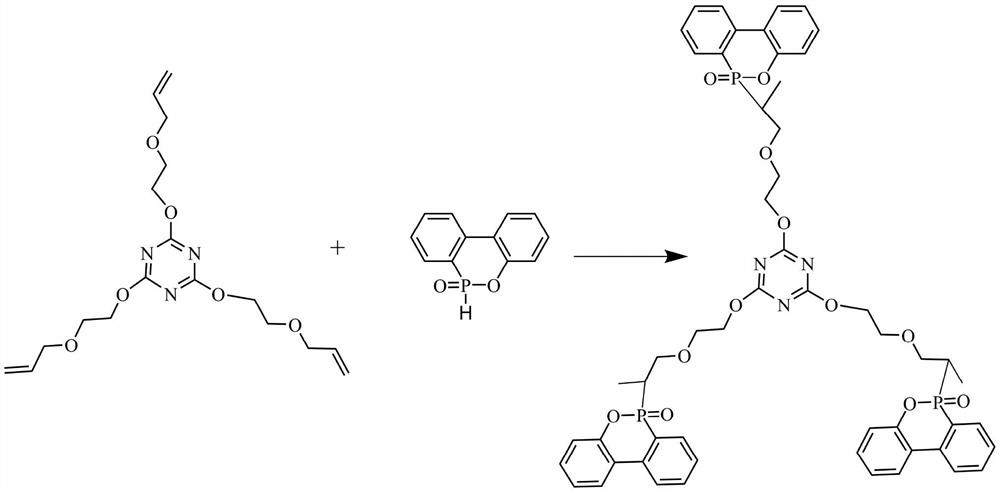

Method used

Image

Examples

Embodiment 1

[0031] 100 parts of water-based acrylic emulsion, 15 parts of triazine-based nitrogen-phosphorus flame retardant, 0.5 part of defoamer, 0.5 part of leveling agent, 1.5 parts of thickener, mix them evenly, and place them in a film-forming plate to form a film.

[0032] The limiting oxygen index (LOI) of the prepared triazine-based nitrogen-phosphorus flame-retardant waterborne acrylic coating increased from 17.8% to 27.3% compared with the blank sample (coating without flame retardant).

Embodiment 2

[0034] 100 parts of water-based acrylic emulsion, 20 parts of triazine-based nitrogen-phosphorus flame retardant, 0.5 parts of defoamer, 0.5 parts of leveling agent, 1.5 parts of thickener, mix them evenly, and place them in a film-forming plate to form a film.

[0035] The limiting oxygen index (LOI) of the prepared triazine-based nitrogen-phosphorus flame-retardant waterborne acrylic coating increased from 17.1% to 29.4% compared with the blank sample (coating without flame retardant).

Embodiment 3

[0037] 100 parts of water-based acrylic emulsion, 25 parts of triazine-based nitrogen-phosphorus flame retardant, 0.5 part of defoamer, 0.5 part of leveling agent, 1.5 parts of thickener, mix them evenly, and place them in a film-forming plate to form a film.

[0038] The limiting oxygen index (LOI) of the prepared triazine-based nitrogen-phosphorus flame-retardant waterborne acrylic coating increased from 18.9% to 33.2% compared with the blank sample (coating without flame retardant).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com