Triazine lignin-based magnetic adsorption material and preparation method thereof

A magnetic adsorption material, lignin-based technology, applied in the field of material science, can solve the problems of refractory degradation, secondary environmental pollution, and high cost of substrates, and achieve the effects of high-capacity adsorption, fast and efficient separation, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the triazine-type lignin-based magnetic adsorption material is characterized in that it specifically includes the following steps:

[0032] lignin and magnetic Fe 3 o 4 Uniformly disperse in the solvent, add cyanuric chloride and alkali catalyst, stir and react at 0-120°C for 2-48 hours. After the reaction is completed, filter, and the solid filtrate is washed to remove unreacted substances, and dried to obtain a triazine-type lignin-based magnetic adsorption material.

[0033] The lignin is any one or more of alkali lignin, organic soluble lignin, acetic acid lignin, lignosulfate, lignosulfonate, high boiling alcohol lignin and enzymatic lignin.

[0034] The magnetic Fe 3 o 4 is hydroxyl magnetic Fe 3 o 4 , Amino magnetic Fe 3 o 4 , Carboxyl magnetic Fe 3 o 4 or mercapto magnetic Fe 3 o 4 any one or more of them.

[0035] The solvent is any one or more of N,N-dimethylacetamide, tetrahydrofuran, 1,4-dioxane, dimethylsulfoxide, tolu...

Embodiment 1

[0040] Add 2.0g alkali lignin, 0.4g magnetic Fe 3 o 4 , 0.4g of potassium carbonate and 100mL of tetrahydrofuran, stirred evenly at room temperature, then added 0.2g of cyanuric chloride, heated to 65°C for 12h. After the reaction was completed, it was cooled to room temperature, and a gray solid was precipitated. After filtering, the filtered solid was washed with tetrahydrofuran, water, and ethanol in sequence to remove unreacted substances, and dried under vacuum at 60° C. to obtain a brown lignin-based magnetic adsorption material (yield 76%).

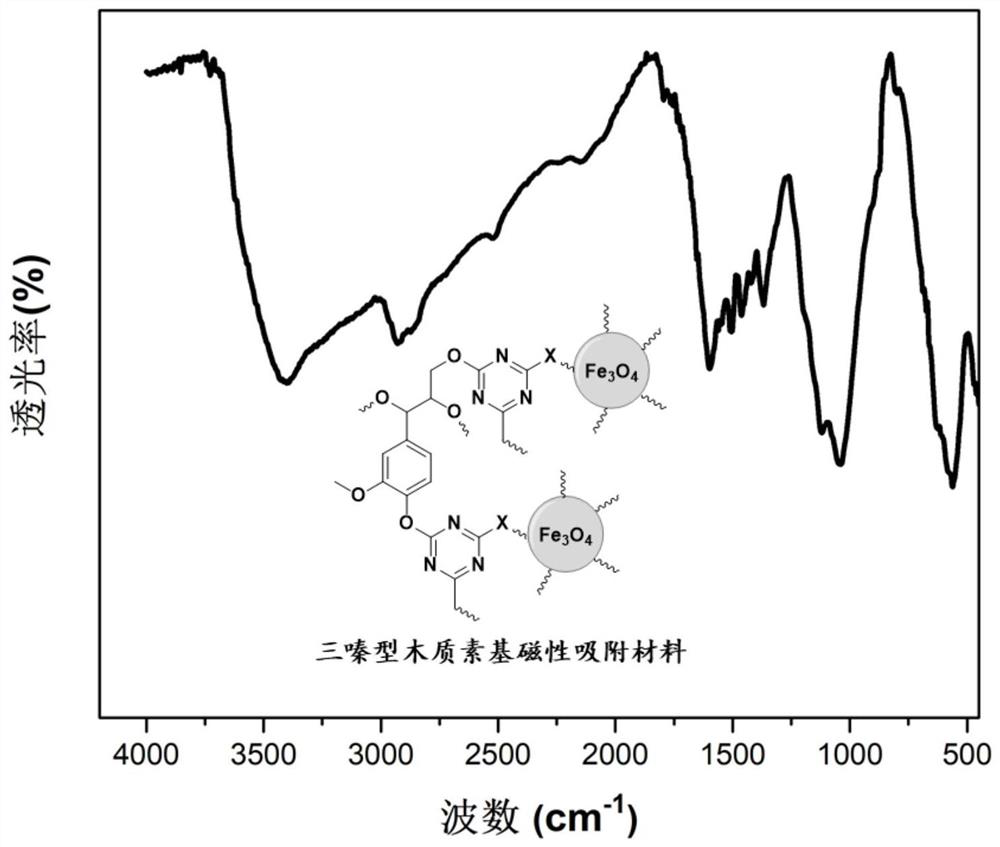

[0041] According to infrared spectrum analysis, the molecular structure of lignin-based magnetic adsorption materials contains functional groups such as hydroxyl and triazine rings ( figure 1 ).

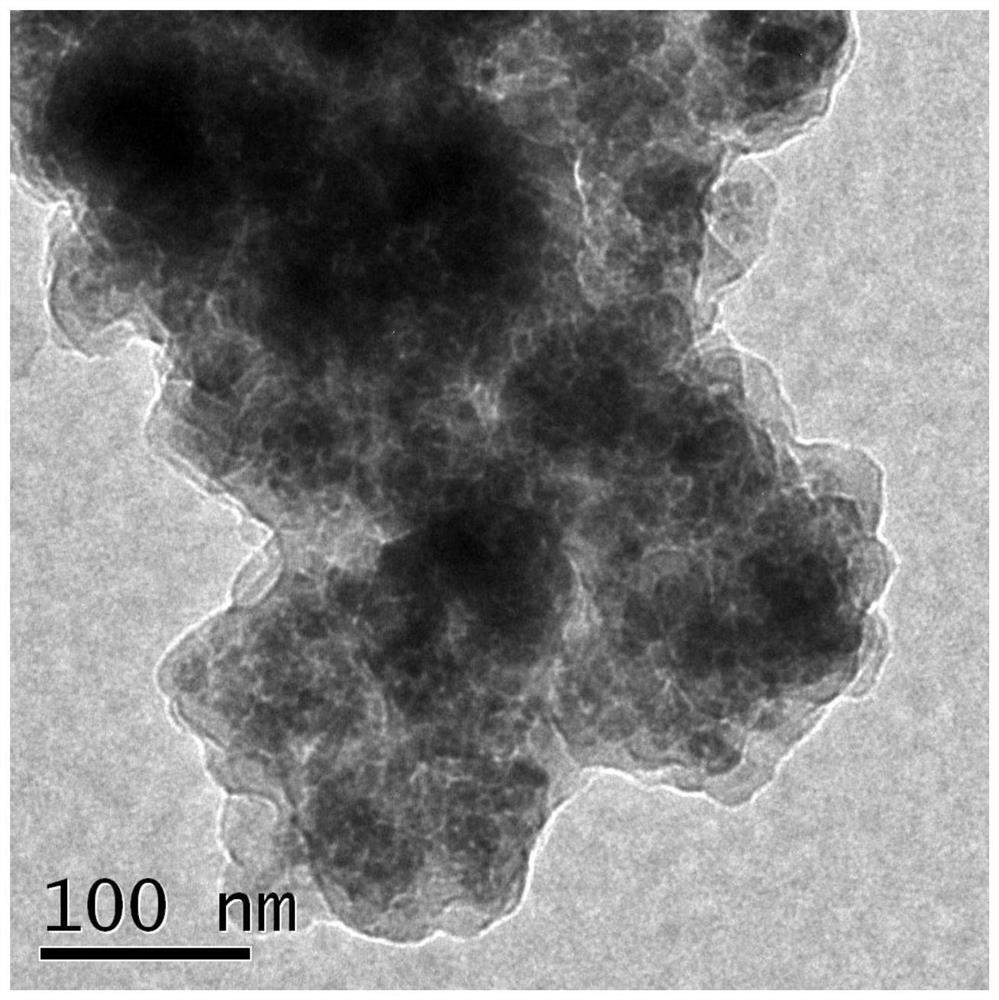

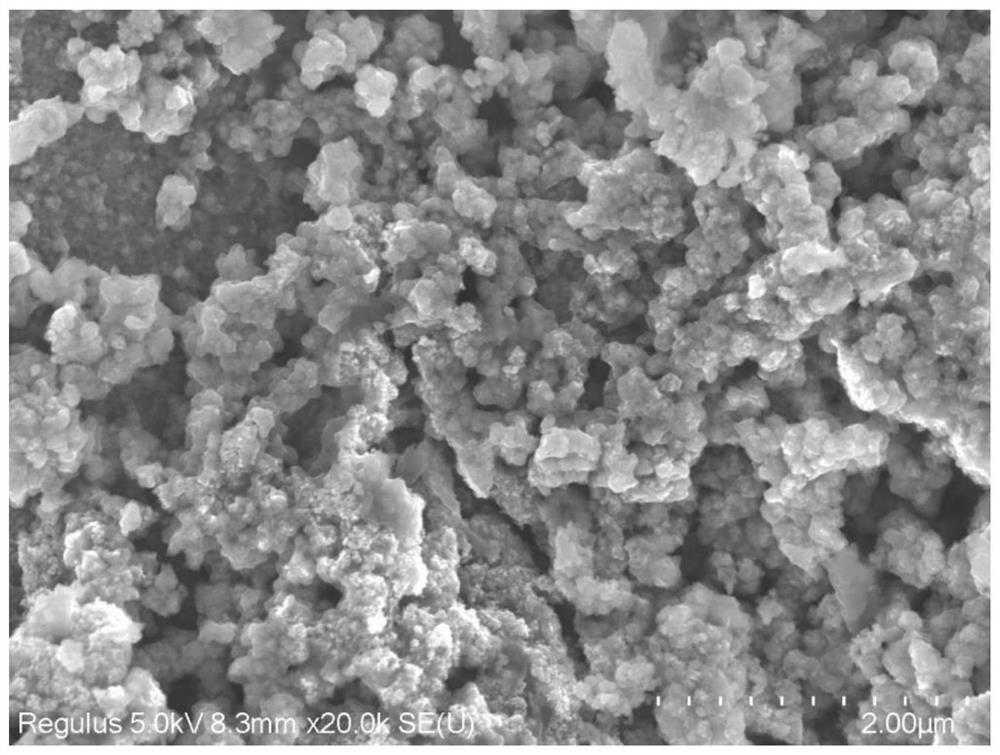

[0042] According to BET analysis, the specific surface area of lignin-based magnetic adsorption material is 137m 2 / g.

[0043] According to the analysis by inductively coupled plasma spectroscopy, the adsorption capacity of the li...

Embodiment 2

[0045] Add 0.55g lignin acetate, 1.1g amine-based magnetic Fe to the three-neck flask 3 o 4 , 0.4g sodium carbonate and 100mL 1,4-dioxane, stirred evenly at room temperature, then added 0.16g cyanuric chloride, heated to 90°C for 10h. After the reaction was completed, it was cooled to room temperature, and a black solid was precipitated. Filtration, the filtered solid was washed with 1,4-dioxane, water, and ethyl acetate to remove unreacted substances, and vacuum-dried at 70°C to obtain a black lignin-based magnetic adsorption material (71% yield) .

[0046] According to BET analysis, the specific surface area of lignin-based magnetic adsorption material is 103m 2 / g.

[0047] According to the analysis by inductively coupled plasma spectroscopy, the adsorption capacity of the lignin-based magnetic adsorption material for Pb(II) ions in an aqueous solution of pH=6 is 137 mg / g.

[0048] The lignin-based magnetic adsorption material has an adsorption capacity of 118 mg / g f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com