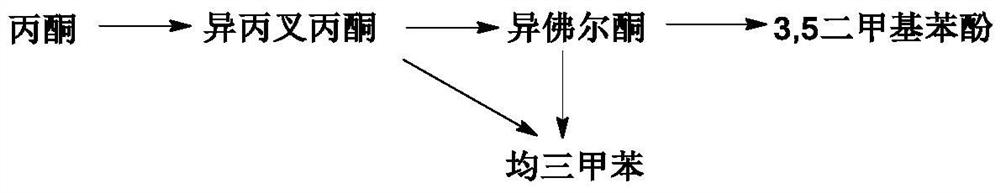

Solid base catalyst for synthesis of 3, 5-dimethylphenol from acetone by vapor phase method, and preparation method and application thereof

A solid base catalyst, dimethylphenol technology, applied in catalyst activation/preparation, preparation of organic compounds, chemical elements of heterogeneous catalysts, etc., can solve the problems of low yield of 3,5 dimethylphenol, etc. The effect of high product selectivity, easy product and less carbon formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) ZrOCl 2 ·8H 2 O 104.6g (0.325mol) was dissolved in distilled water to prepare a solution with a Zr concentration of 0.1mol / L, and La(NO) was added. 3 ) 3 0.32g (0.000985mol), heated in a water bath to 70°C, add 10wt% ammonia water dropwise under stirring at 300rpm to adjust the pH to 9-10, continue stirring for 1.5h to fully react to obtain a suspension, and then at room temperature Aged at 25°C for 20h, the reaction solution was filtered and washed until no chloride ions were present, then dried at 100°C for 10h, and ZrO with a particle size of 3-5mm was sieved after grinding. 2 / La 2 O 3 composite carrier;

[0059] (2) Take Sr (NO 3 ) 2 , Ca(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O 3.67g (0.01734mol), 6.58g (0.04012mol), 2.966g (0.01019mol), wherein strontium: calcium: cobalt mass ratio is 1: 1.05: 0.4, after mixing, add 200g distilled water to prepare a solution, step ( 1) ZrO 2 / La 2 O 3 40 g of the composite carrier was added to the solution, left to sta...

Embodiment 2

[0062] (1) Zr (SO 4 ) 2 91.95g was dissolved in distilled water to prepare a solution with a Zr concentration of 0.06mol / L, and La(NO) was added. 3 ) 3 0.66g, heated in a water bath to 70°C, add 15% ammonia water dropwise under stirring to adjust pH to 9-10, continue stirring to fully react for 1.5h to obtain a suspension, and then age at room temperature for 25h, the reaction The liquid was filtered and washed until there was no chloride ion, and then dried at 110 °C for 8 hours. After grinding, ZrO with a particle size of 3 to 5 mm was sieved. 2 / La 2 O 3 composite carrier.

[0063] (2) Take Sr(Cl) respectively 2 , Ca(Cl) 2 , Co(Cl) 2 3.60g, 6.53g, 1.96g, wherein the mass ratio of strontium: calcium: cobalt is 1: 1.18: 0.45, after mixing, add 200g of distilled water to prepare a solution, mix the ZrO of step (1) 2 / La 2 O 3 40 g of the composite carrier was added to the solution, left to stand for 14 hours of immersion, taken out and dried at 100 °C for 8 hours,...

Embodiment 3

[0066] (1) ZrOCl 2 ·8H 2 O 104.6g was dissolved in distilled water to prepare a solution with a Zr concentration of 0.08mol / L, and La(NO) was added. 3 ) 3 0.40g, heated in a water bath to 70°C, add 15% ammonia water dropwise under stirring to adjust pH to 9-10 to make it fully react, continue stirring for 1.5h to obtain a suspension, then age at room temperature for 25h, The reaction solution was filtered and washed until there was no chloride ion, and then dried at 110 °C for 8 hours. After grinding, ZrO with a particle size of 3 to 5 mm was sieved. 2 / La 2 O 3 composite carrier.

[0067] (2) Take SrSO separately 4 , Ca(NO 3 ) 2 , CoSO 4 1.53g, 3.78g, 1.42g, wherein the mass ratio of strontium: calcium: cobalt is 1:1.27:0.74, after mixing, add 200g of distilled water to prepare a solution, mix the ZrO of step (1) 2 / La 2 O 3 40 g of the composite carrier was added to the solution, left to stand for 16 hours, dried at 100 °C for 8 hours, and then heated to 750 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com