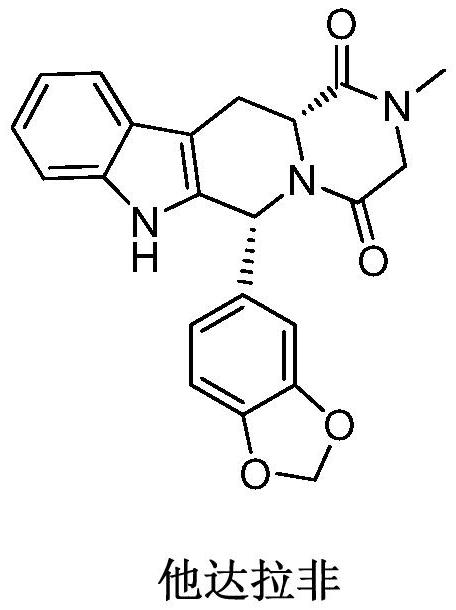

A kind of preparation method of tadala amorphous form I

A technology of tadalafil and crystal form, which is applied in the field of chemical pharmacy, can solve the problems of high cost of recovery and application of mixed solvents, high requirements for labor protection of workshop workers, and difficult removal of acetic acid residues, so as to be beneficial to energy saving, emission reduction and environmental protection , The effect of low labor protection requirements and low cost in the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of tadalafil crude product is according to literature:

[0031] Yao Shaobo, Cai Mingde, Lu Xiaoyi, etc. Synthesis of Tadalafil, Fine Chemical Intermediates[J].2010,40(6):39-42.

[0032] 520 g of crude tadalafil was prepared, and the product purity (HPLC normalization method, the same below): 98.99%.

Embodiment 1

[0034] Under nitrogen protection, add 150mL of acetonitrile aqueous solution (10:1 by volume), 10.0g of crude tadalafil, and 0.05g of SDS to the three-neck flask successively, stir for 10min, heat to 65-70°C, the system is dissolved, and then depressurize About 30mL of solvent was distilled off. After the evaporation was complete, the temperature of the system was lowered to -5-0°C, crystallized for 1 hour, filtered, washed with purified water at 40-50°C, and the filter cake was dried under reduced pressure at 50-60°C to obtain tadalafil ( Crystal form I) 9.16g, yield 91.6%.

Embodiment 2

[0036] Under the protection of nitrogen, 100mL of acetonitrile aqueous solution (volume ratio 6:1), 10g of crude tadalafil, and 0.25g of SDS were successively added to the three-neck flask, stirred for 10min, heated to 70-80°C, the system was dissolved, and then evaporated under reduced pressure. About 33mL of solvent was removed, after evaporation was complete, the system was cooled to 0-5°C, crystallized for 3 hours, washed with purified water at 40-50°C, filtered, and the filter cake was dried under reduced pressure at 50-60°C to obtain tadalafil (crystalline form Ⅰ) 9.29g, yield 92.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com