System and method for producing powdery vanadium by using chlorination process

A chlorination method and powder vanadium technology, applied in the fields of chemical industry and metallurgy, can solve the problems of low recovery rate, difficulty in rectification purification and chlorination residue treatment, and increase in production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

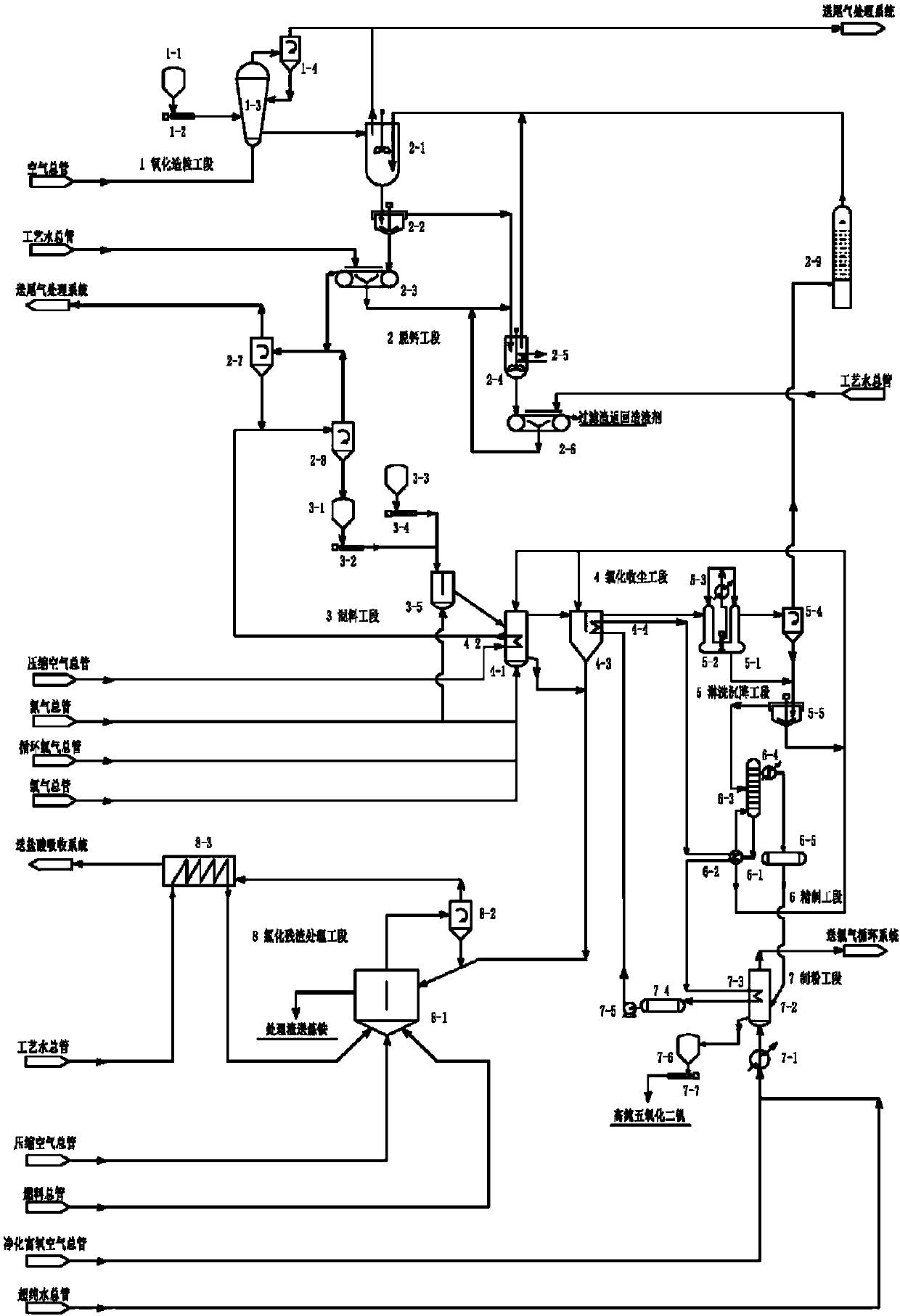

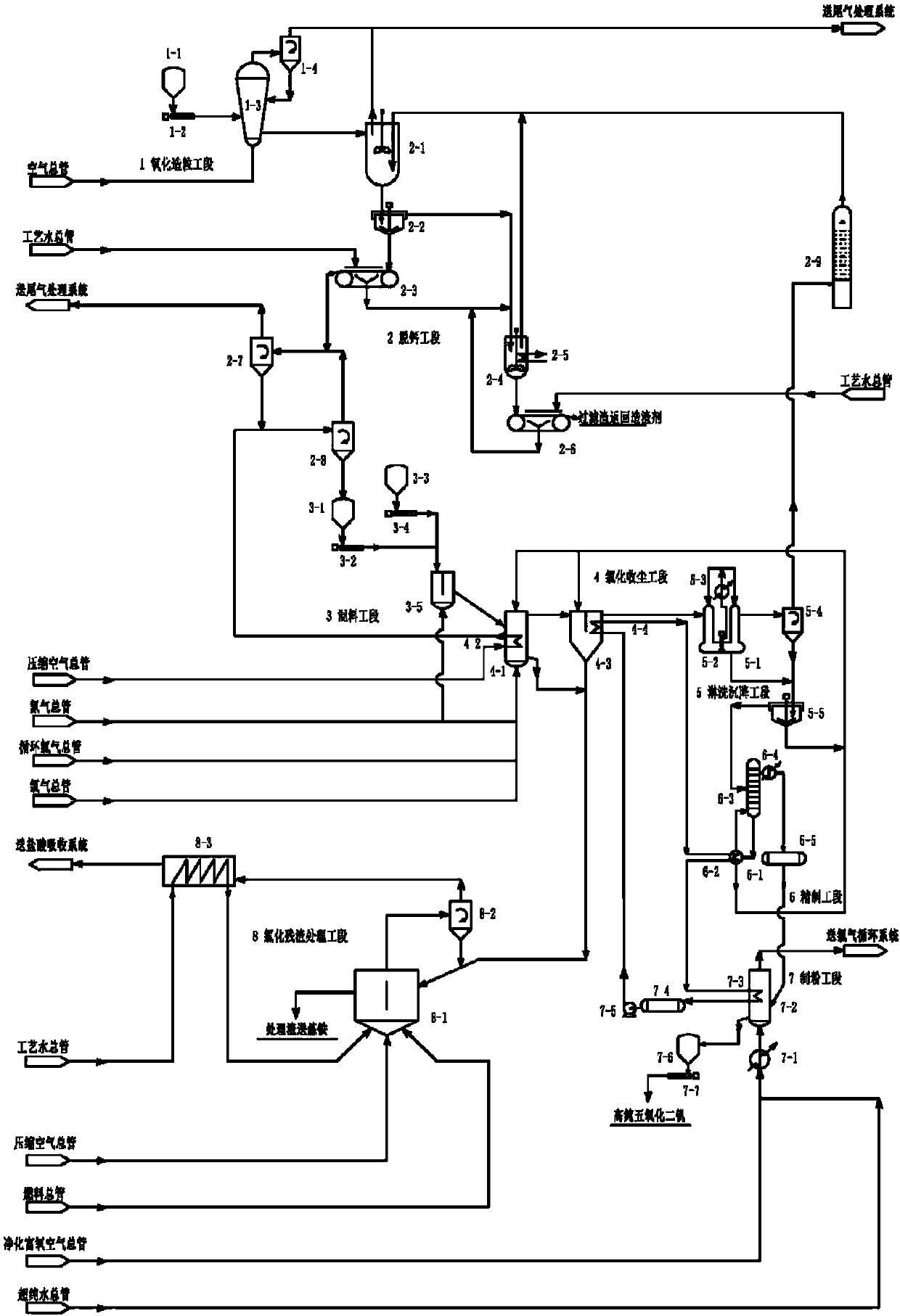

[0080] combine figure 1 , a system for producing vanadium powder by chlorination method used in this embodiment, including oxidation granulation section 1, decalcification section 2, mixing section 3, chlorination and dust collection section 4, leaching and sedimentation section 5, and refining section 6. Milling section 7 and chlorination residue treatment section 8;

[0081] Oxidation and granulation section 1 includes vanadium slag silo 1-1, vanadium slag screw feeder 1-2, oxidation granulation fluidized bed 1-3 and vanadium slag cyclone dust collection tower 1-4;

[0082] Decalcification section 2 includes decalcification stirring tank 2-1, decalcification slurry settling tank 2-2, No. 1 decalcification washing filter 2-3, decalcification evaporative crystallizer 2-4, decalcification heater 2-5 , No. 2 decalcification washing filter 2-6, No. 1 decalcification cyclone preheater 2-7, No. 2 decalcification cyclone preheater 2-8 and alkali washing tower 2-9;

[0083] Mixing ...

Embodiment 2

[0094] Adopt the system described in embodiment 1, present embodiment provides a kind of method for producing vanadium powder by chlorination, comprising the following steps:

[0095] The vanadium slag in the vanadium slag silo 1-1 enters the oxidation granulation fluidized bed 1-3 through the vanadium slag screw feeder 1-2, and undergoes an oxidation reaction with the air from the air main pipe, accompanied by particle growth; The operating temperature of oxidation granulation fluidized bed 1-3 is 400°C~1000°C; the reaction tail gas is sent to the tail gas treatment system after the dust is removed by the vanadium slag cyclone dust collection tower 1-4; The carbon dioxide-enriched distilled water from device 2-4 enters into the decalcification stirred tank 2-1 together, and carbonization reaction occurs with the carbon dioxide-enriched gas from the alkali washing tower 2-9, and the calcium oxide is converted into water-soluble carbonate; the reaction slurry The material enter...

Embodiment 3

[0099] This embodiment takes steelmaking vanadium slag as raw material, wherein the mass fraction of vanadium pentoxide is 8%, the mass fraction of calcium oxide is 2.5%, the mass fraction of phosphorus oxide is 0.1%, and the processing capacity is 1.3t / h. Oxidation granulation, decalcification treatment, mixing, chlorination dust collection, leaching and sedimentation, refining, pulverization and other processes to prepare high-purity vanadium pentoxide products, and realize industrial waste energy utilization and residue treatment through waste heat utilization and residue treatment Dechlorination treatment.

[0100]In the oxidation granulation fluidized bed 1-3, the oxidation roasting temperature is 400°C, the operating gas velocity is 0.05m / s, and the average residence time of the vanadium slag is 30min; in the decalcification section 2, the calcium decalcification The removal rate is 96%; in the fluidized bed mixer 3-5, the metallurgical coke dosage is 5% of the decalcifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com