A kind of synthetic method of chlorophenoxyacetic acid or chlorophenol

The technology of a chlorophenoxyacetic acid and a synthesis method is applied in the field of synthesis of chlorophenoxyacetic acid or chlorophenol, and can solve the problems of increased product difficulty, poor chlorination selectivity, and high cost of hydrochloric acid, and can reduce the chlorination activity. , Improve chlorination selectivity, simplify the effect of chlorination process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

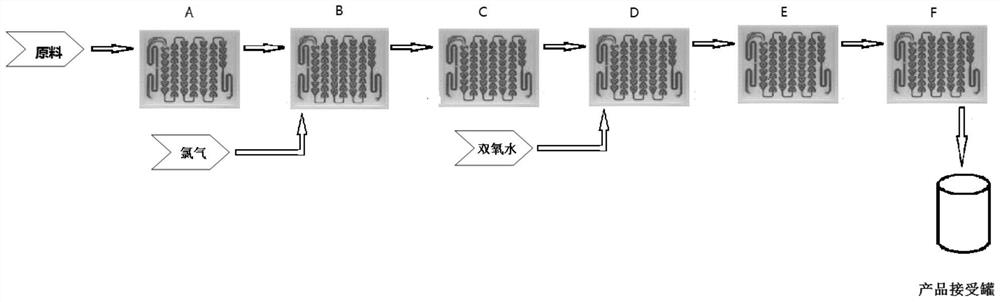

Method used

Image

Examples

Embodiment 12

[0033] Embodiment 1 2, the synthesis of 4-dichlorophenol

[0034] In a 1000 ml four-necked flask equipped with stirring, thermometer, reflux condenser and dropping funnel, add 380 g of phenol (4 moles, mass content 99%), stir and heat to 60 ° C, start to feed chlorine gas, and feed chlorine gas to 35 g (0.5 moles), start to add hydrogen peroxide (30%) dropwise, feed 355g (5 moles) to chlorine gas, add 360g (3.2 moles) to hydrogen peroxide dropwise, stop logical chlorine gas and drip hydrogen peroxide, continue to insulate for 1 hour to stop the reaction, keep warm The layers were separated, and the organic phase was cooled to obtain 646 g of the product 2,4-dichlorophenol, with a mass content of 99% detected by HPLC and a yield of 98.1%; the water phase was sent to a waste water treatment station.

Embodiment 2

[0035] The synthesis of embodiment 2 2-methyl-4-chlorophenol

[0036] Add o-cresol 218g (2 moles, mass content 99%) in a 1000 milliliter four-necked bottle equipped with stirring, thermometer, reflux condenser and dropping funnel, heat to 65 ℃, start logical chlorine gas, logical chlorine gas to 11g (0.15 mole), simultaneously drip hydrogen peroxide (content 30%), feed 85g (1.2 mole) to chlorine gas, hydrogen peroxide drips and add 80g (0.7 mole), stop logical chlorine gas and drip hydrogen peroxide, continue to insulate for 0.5 hour to stop reaction, After heat preservation and standing for stratification, the organic phase was cooled to obtain 284.3 g of the product, the mass content of which was detected by HPLC was 98.5%, and the yield was 98.2%; the water phase was sent to the wastewater treatment station.

Embodiment 3

[0037] Embodiment 3 2, the synthesis of 4-dichlorophenoxyacetic acid

[0038] In a 2000ml reaction bottle, add 1000g of phenoxyacetic acid dichloroethane solution [containing 152g (1 mole) of phenoxyacetic acid] and heat to 75°C, start to pass chlorine gas, and pass chlorine gas to 21g (0.3 mole), while adding Hydrogen peroxide (content 30%), until 80g (1.15 mol) of chlorine gas is passed into, 90g (0.80 mol) of hydrogen peroxide is added dropwise, stop the flow of chlorine gas and dropwise addition of hydrogen peroxide, continue to keep warm for 1 hour to stop the reaction, leave to stand and separate, and the organic phase is concentrated and recovered solvent to obtain 220 g of the product 2,4-dichlorophenoxyacetic acid, the mass content of which was detected by HPLC was 98.7%, and the yield was 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com