Method for preparing vanadium pentoxide/graphene composite aerogel material

A vanadium pentoxide sol and vanadium pentoxide technology, applied in the field of electrochemistry, can solve problems affecting the overall performance of capacitors, poor aerogel conductivity, and large internal resistance of capacitors, and achieve light weight, low cost, and high power density. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

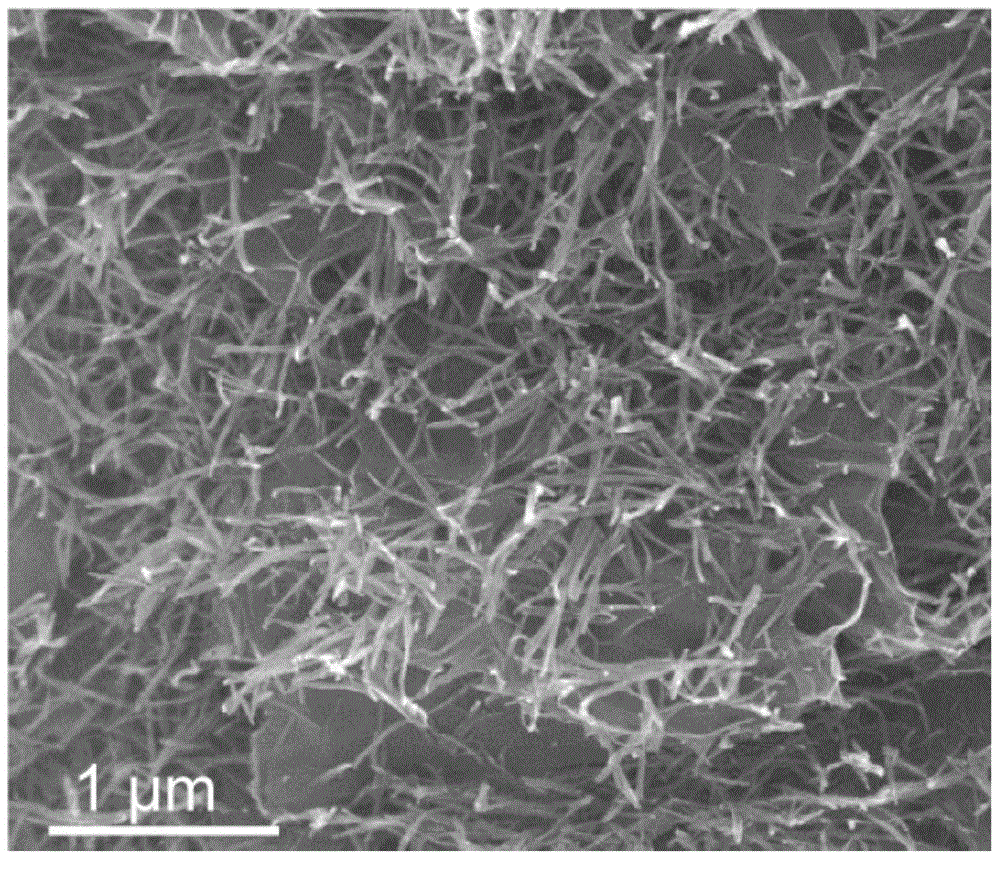

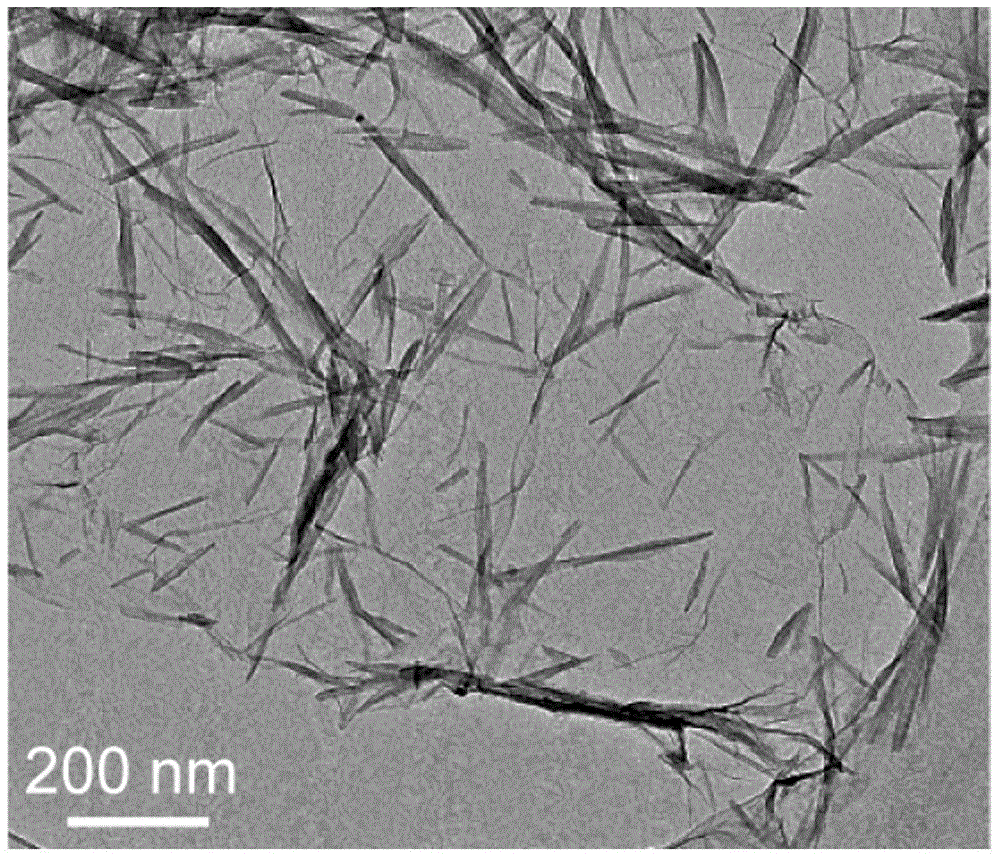

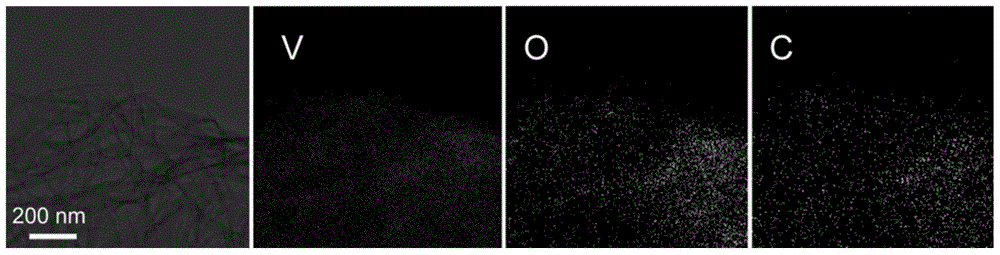

[0033] Stir and mix 30g of vanadium pentoxide powder, 17.5ml of benzyl alcohol and 500ml of isopropanol (molar ratio 1:1:40), reflux and condense at 90°C for 4 hours, filter and recover unreacted vanadium pentoxide powder to obtain Vanadium pentoxide sol. The obtained vanadium pentoxide sol was concentrated by distillation at 100°C to 1 / 2 of the original volume to obtain concentrated vanadium pentoxide sol. 15ml of graphene oxide aqueous dispersion with a concentration of 2mg / ml and 1ml of formic acid were added to the concentrated vanadium pentoxide sol, stirred for 1 minute and aged at 50°C for 2 days to obtain a vanadium pentoxide / graphene oxide wet gel. The vanadium pentoxide / graphene oxide wet gel was soaked in acetone, the solvent was replaced for 2 days, and the vanadium pentoxide / graphene oxide composite airgel was obtained after supercritical drying with carbon dioxide. The vanadium pentoxide / graphene oxide composite airgel was heat-treated in air at 300° C. for 3 ho...

Embodiment 2

[0036]30g of vanadium pentoxide powder, 35ml of benzyl alcohol and 750ml of isopropanol (molar ratio 1:2:60) were stirred and mixed, refluxed and condensed at 95°C for 4 hours, filtered and unreacted vanadium pentoxide powder was recovered to obtain five Vanadium oxide sol. The obtained vanadium pentoxide sol was concentrated by distillation at 100°C to 1 / 3 of the original volume to obtain concentrated vanadium pentoxide sol. 15ml of graphene oxide aqueous dispersion with a concentration of 4mg / ml and 1ml of acetic acid were added to the concentrated vanadium pentoxide sol, stirred for 1 minute and aged at 50°C for 3 days to obtain a vanadium pentoxide / graphene oxide wet gel. The vanadium pentoxide / graphene oxide wet gel was soaked in methanol, the solvent was replaced for 2 days, and the vanadium pentoxide / graphene oxide composite airgel was obtained after freeze-drying. The vanadium pentoxide / graphene oxide composite airgel was heat-treated in air at 350° C. for 3 hours to ...

Embodiment 3

[0039] 30g of vanadium pentoxide powder, 70ml of benzyl alcohol and 500ml of isopropanol (molar ratio 1:4:40) were stirred and mixed, refluxed and condensed at 100°C for 4 hours, filtered and unreacted vanadium pentoxide powder was recovered to obtain five Vanadium oxide sol. The obtained vanadium pentoxide sol was concentrated by distillation at 100°C to 2 / 5 of the original volume to obtain concentrated vanadium pentoxide sol. 15ml of graphene oxide aqueous dispersion with a concentration of 6mg / ml and 2ml of acetic acid were added to the concentrated vanadium pentoxide sol, stirred for 2 minutes and aged at 50°C for 3 days to obtain a vanadium pentoxide / graphene oxide wet gel. The vanadium pentoxide / graphene oxide wet gel was soaked in ethanol, the solvent was replaced for 2 days, and the vanadium pentoxide / graphene oxide composite airgel was obtained after freeze-drying. The vanadium pentoxide / graphene oxide composite airgel was heat-treated at 400° C. in the air for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com