Nano vanadium oxide and preparation method thereof

A vanadium oxide and nanotechnology, which is applied in the field of oxides and preparation, can solve problems such as easy agglomeration, small size, unfavorable excellent performance, etc., and achieve the effect of scientific preparation method, increase of specific surface area, and expansion of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific steps of preparation are:

[0030] Step 1. Put the vanadium pentoxide powder at 800° C. to melt and heat it for 24 minutes to obtain a vanadium pentoxide melt. Then, the vanadium pentoxide melt is immersed in a quenching medium under stirring for 12 hours, and then left to stand for 10 days to age; wherein the quenching medium is deionized water to obtain a vanadium pentoxide sol.

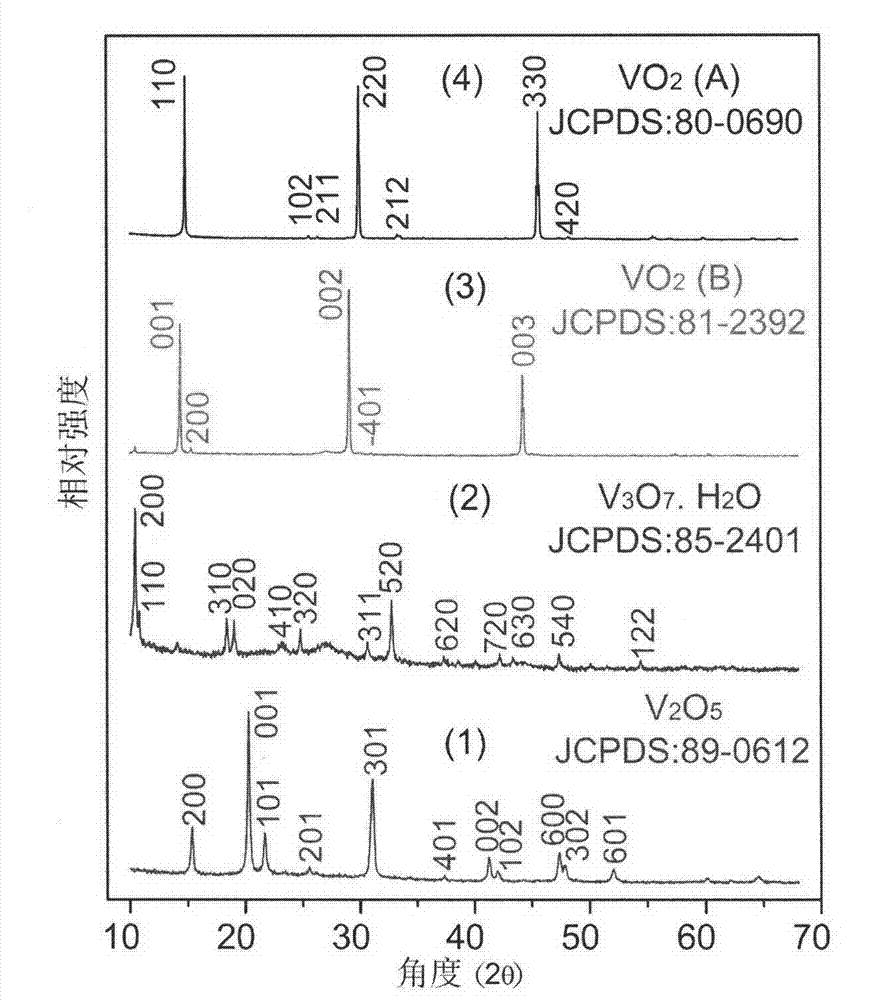

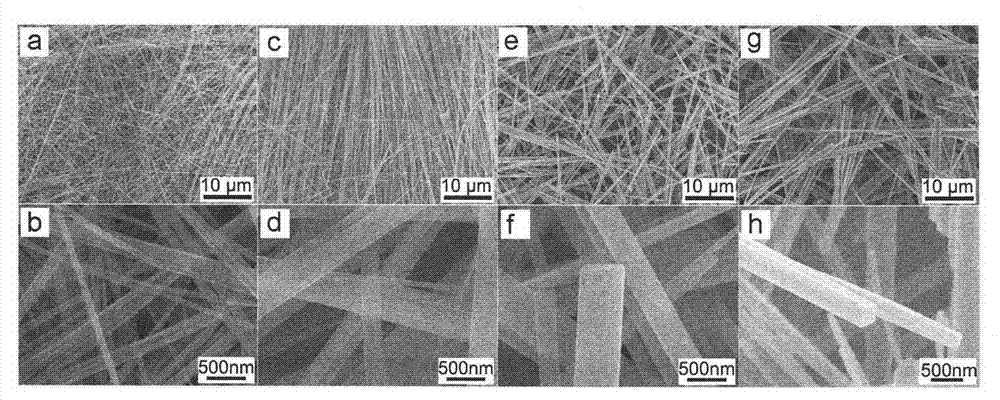

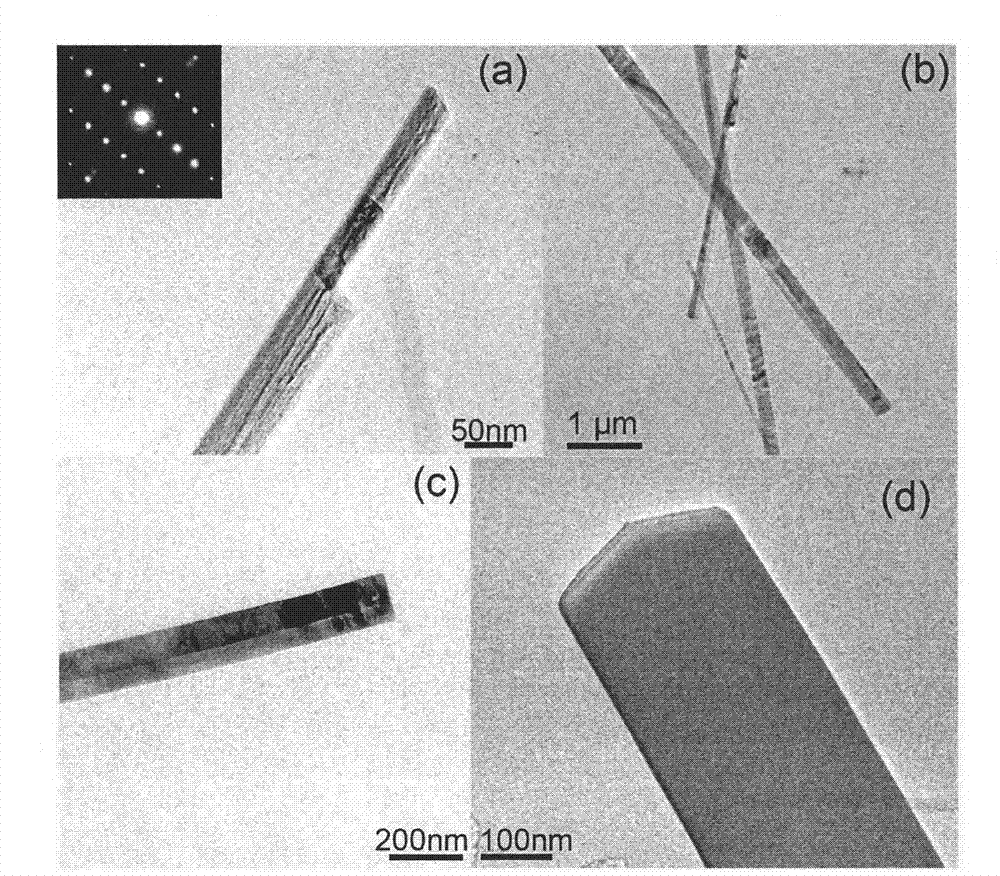

[0031] Step 2. Put the vanadium pentoxide sol in a closed state and hydrothermally react at 200°C for 6 days to prepare figure 1 As shown in curve 1 and approximate figure 2 a. figure 2 b and image 3 The nano vanadium pentoxide shown in a.

[0032] Or, first add polyethylene glycol to the vanadium pentoxide sol and stir for 2 hours; wherein the molar ratio between polyethylene glycol and vanadium pentoxide is 1:5, and polyethylene glycol is polyethylene glycol-6000 , Get a mixed solution. Then put the mixed solution in an airtight state, and hydrothermally react at 220°C for 0.5h ...

Embodiment 2

[0036] The specific steps of preparation are:

[0037] Step 1. Put the vanadium pentoxide powder at 830° C. to melt and heat it for 23 minutes to obtain a vanadium pentoxide melt. Then, the vanadium pentoxide melt was immersed in a quenching medium under stirring for 12.5 hours, and then allowed to stand and age for 10.5 d; wherein the quenching medium was distilled water to obtain a vanadium pentoxide sol.

[0038] Step 2. Put the vanadium pentoxide sol in a closed state and hydrothermally react at 205°C for 4.5 days to obtain figure 1 As shown in curve 1 and approximate figure 2 a. figure 2 b and image 3 The nano vanadium pentoxide shown in a.

[0039] Or, first add polyethylene glycol to the vanadium pentoxide sol and stir for 2.5 hours; wherein the molar ratio between polyethylene glycol and vanadium pentoxide is 1:12, and polyethylene glycol is polyethylene glycol- 6000, to obtain a mixed solution. Then put the mixed solution in a closed state, hydrothermally react at 230℃ ...

Embodiment 3

[0041] The specific steps of preparation are:

[0042] Step 1. Put the vanadium pentoxide powder at 850° C. to melt and heat it for 22 minutes to obtain a vanadium pentoxide melt. Then, the vanadium pentoxide melt was immersed in the quenching medium under stirring for 13 hours, and then allowed to stand and age for 11 days; where the quenching medium was deionized water, a vanadium pentoxide sol was obtained.

[0043] Step 2. Put the vanadium pentoxide sol in a sealed state, and hydrothermally react at 210°C for 3 days to obtain figure 1 As shown in curve 1 in figure 2 a. figure 2 b and image 3 The nano vanadium pentoxide shown in a.

[0044] Or, first add polyethylene glycol to the vanadium pentoxide sol and stir for 3 hours; wherein the molar ratio between polyethylene glycol and vanadium pentoxide is 1:18, and polyethylene glycol is polyethylene glycol-6000 , Get a mixed solution. Then put the mixed solution in a closed state, hydrothermally react at 240℃ for 11h, or 48h, or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com