Method for low temperature preparing lithium ion battery positive pole material fluorophosphoric acid vanadium lithium

A lithium-ion battery, lithium vanadium fluorophosphate technology, applied in battery electrodes, circuits, electrode manufacturing, etc., can solve the problem of poor electrical conductivity and cycle performance, uneven particle size distribution of synthetic materials, uneven particle size distribution of materials, etc. problem, to achieve the effect of easy control, suppression of excessive growth, and simple and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

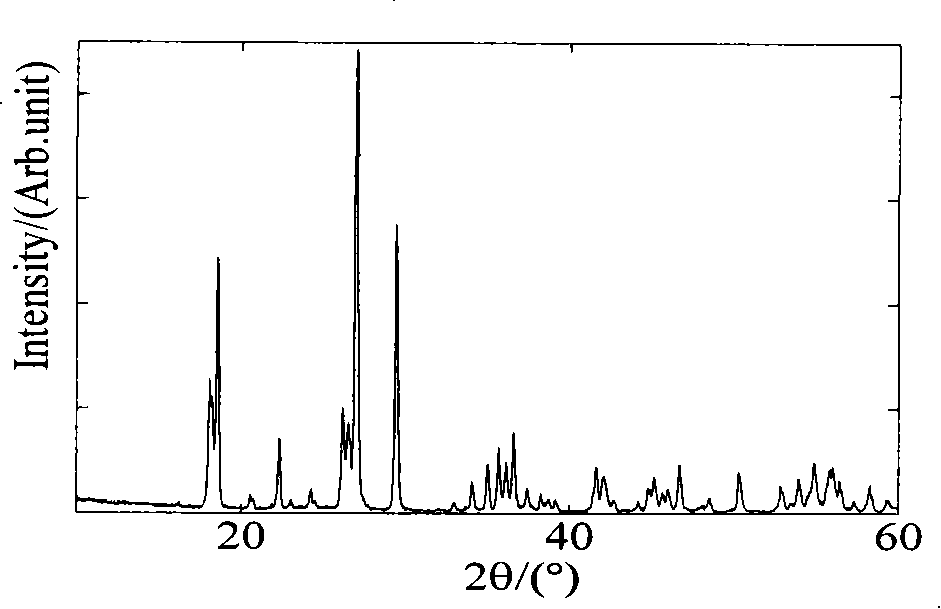

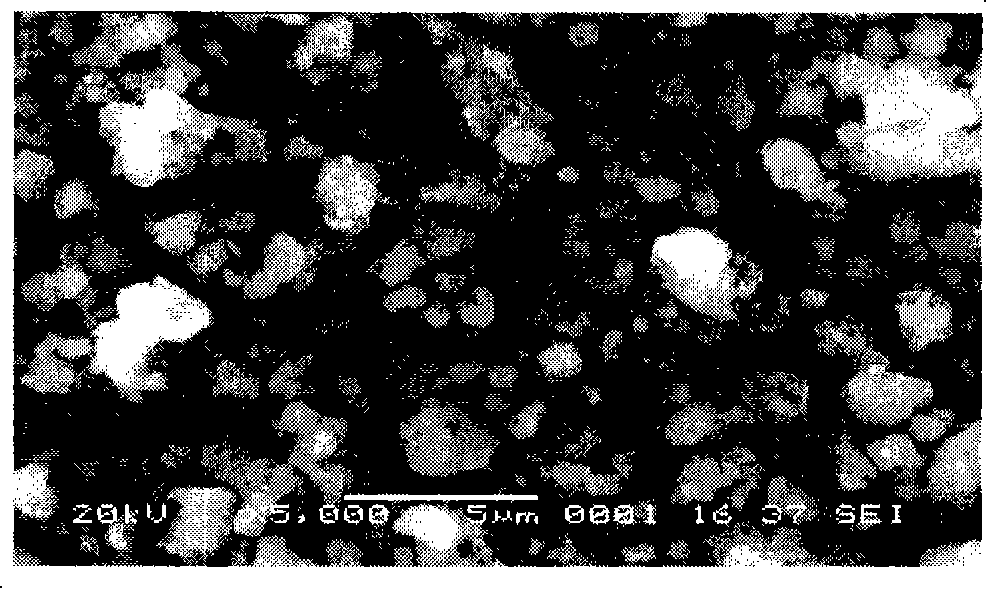

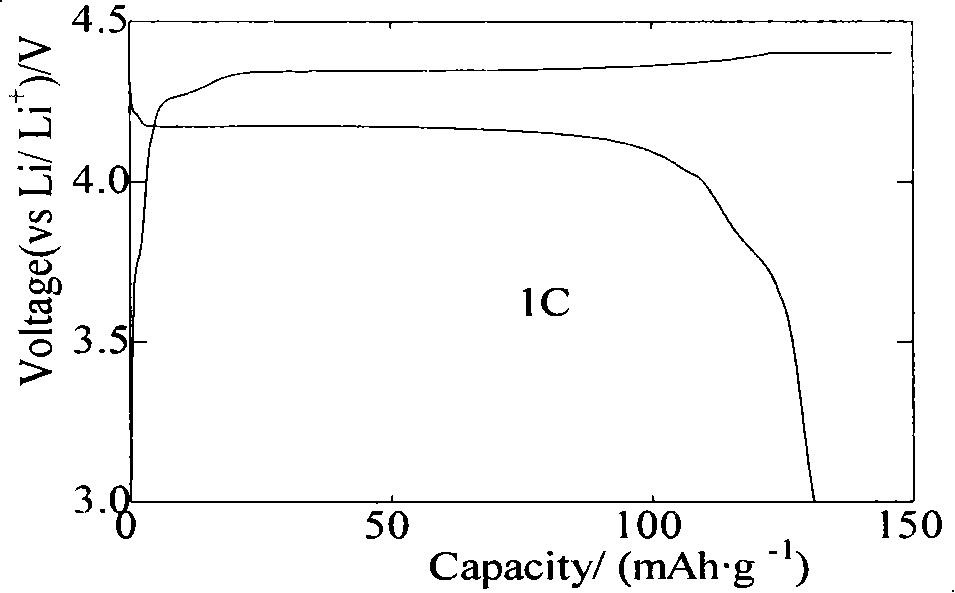

[0017] Heat 0.1mol vanadium pentoxide powder to 600°C, keep the temperature for 4 hours to make it melt, and then quickly pour it into a container filled with water to form a brownish red solution, which can be formed after standing for 16 hours. 2 o 5 ·nH 2 O wet gel. The wet gel was washed to remove most of the moisture, then vacuum-dried at 70° C. for 16 hours, and ground to obtain vanadium pentoxide gel powder. Mix the prepared vanadium pentoxide gel powder with 0.2mol of lithium acetate, 0.2mol of ammonium fluoride, 0.2mol of diammonium hydrogen phosphate and 0.24mol of acetylene black, and then place them at 400°C, 500°C, and Sintering at 600°C and 700°C for 5 hours, then finished LiVPO after cooling 4 F. The obtained products were analyzed by X-ray diffraction, showing that they were all LiVPO 4 F, without any impurity phase, the particle size of the product obtained by SEM is about 1 μm. The obtained product was assembled into an experimental button battery to me...

Embodiment 2

[0021] Heat 0.1mol vanadium pentoxide powder to 900°C, keep the temperature constant for 1 hour to melt the vanadium pentoxide, then quickly pour it into a container filled with water to form a brownish-red solution, and leave the solution for 12 hours to form V 2 o 5 ·nH 2 O wet gel. Wash the wet gel to remove most of the moisture, then vacuum-dry it at 90° C. for 12 hours, and grind it to obtain vanadium pentoxide gel powder. After mixing the prepared vanadium pentoxide gel powder with 0.2mol lithium fluoride, 0.2mol sodium fluoride, 0.2mol ammonium dihydrogen phosphate and 0.24mol acetylene black, they were sintered at 600°C under the protection of argon for 5 , 10, 15 and 20h, after cooling, the finished product LiVPO 4 F. The obtained products were analyzed by X-ray diffraction, showing that they were all LiVPO 4 F, without any impurity phase, the particle size of the product obtained by SEM is about 1 μm. The obtained product was assembled into an experimental butt...

Embodiment 3

[0025] Heat 0.1mol vanadium pentoxide powder to 800°C, keep the temperature constant for 2 hours to melt it, then quickly pour it into a container filled with water to form a brown-red solution, and the solution can be formed after standing for 4 hours. 2 o 5 ·nH 2 O wet gel. The wet gel was washed to remove most of the water, then vacuum-dried at 100° C. for 8 hours, and ground to obtain vanadium pentoxide gel powder. After mixing the prepared vanadium pentoxide gel powder with 0.2mol lithium chloride, 0.2mol potassium fluoride, 0.2mol potassium phosphate and 0.24mol acetylene black, they were heated at 450°C and 550°C under the protection of argon , 650°C, 700°C sintering for 20h, after cooling, the finished LiVPO 4 F. The obtained products were analyzed by X-ray diffraction, showing that they were all LiVPO 4 F, without any impurity phase, the particle size of the product obtained by SEM is about 1 μm. The obtained product was assembled into an experimental button bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com